Hi, what do you think about the inductors, the air core ones are better than the conventional ones and for the frequency cut-off of the MKP or electrolytic BP condenser bass?

You need to provide a bit more background about your xover and loudspeaker. Can you maybe post a circuit and some information about your loudspeaker?

Saying "air core inductors are better than iron cores" is like saying that "beer is better than a burger". However, the right choice really depends on what you need... if you are thirsty, I'd recommend the beer. If you're hungry, go for the burger.

Saying "air core inductors are better than iron cores" is like saying that "beer is better than a burger". However, the right choice really depends on what you need... if you are thirsty, I'd recommend the beer. If you're hungry, go for the burger.

Learn about air-core and core inductors here: https://cdn.shopify.com/s/files/1/0809/2387/files/Inductors_for_passive_filtercircuits.pdf?5141

Regarding MKP and electrolytic capacitors: A capacitor with the lowest dissipation factor* shows the least signal distortions. For crossover applications, polypropylene dielectric versions are, in principle, the most suitable as they have the lowest dissipation factor.

*Dissipation factor is a measure of the energy loss in a capacitor. Energy is lost because the AC signal causes the polarity of the dielectric (e.g. polypropylene) to change continuously and the resulting friction in its molecular structure converts electrical energy into heat.

Regarding MKP and electrolytic capacitors: A capacitor with the lowest dissipation factor* shows the least signal distortions. For crossover applications, polypropylene dielectric versions are, in principle, the most suitable as they have the lowest dissipation factor.

*Dissipation factor is a measure of the energy loss in a capacitor. Energy is lost because the AC signal causes the polarity of the dielectric (e.g. polypropylene) to change continuously and the resulting friction in its molecular structure converts electrical energy into heat.

Air core coils don’t suffer from saturating problems, so they are the “best”. However it all depends on the application, there are situations where the only sensible component to use is a correct sized cored coil.

The same principle works for caps. Even if MKP caps should be preferred for crossover duties there are situations where an electrolytic cap is fine, or is the most sensible component to use. Even Troels Gravesen, who is a fan of exotic caps, uses electrolytic caps in some situations. Again, a schematic of the crossover and the drivers involved would allow to pick the better components for the task.

Ralf

The same principle works for caps. Even if MKP caps should be preferred for crossover duties there are situations where an electrolytic cap is fine, or is the most sensible component to use. Even Troels Gravesen, who is a fan of exotic caps, uses electrolytic caps in some situations. Again, a schematic of the crossover and the drivers involved would allow to pick the better components for the task.

Ralf

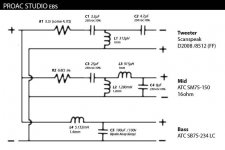

The schematic is over on the OP's 'Proac crossover' thread, Ralf - presuming he is still referring to this speaker.

Attachments

Last edited:

crossover proac ebs

If that is the scheme though I still have the problem of replacing the sm75-150 16h atc media speaker with an 8ohm one which I have made several changes and I don't think it sounds like the original one

If that is the scheme though I still have the problem of replacing the sm75-150 16h atc media speaker with an 8ohm one which I have made several changes and I don't think it sounds like the original one

Air core coils don’t suffer from saturating problems

Sure. And they need much more wire to get to the same inductance than an iron-core inductor. Air cores therefore have much higher DC resistance. It is possible to compensate this by using a larger diameter wires, but there are limits. For instance, I have never seen a 6.8 mH / 0.2 Ohm air-core inductor.

The schematic is over on the OP's 'Proac crossover' thread, Ralf - presuming he is still referring to this speaker.

Unfortunately this schematic does not specify the DC resistance of the inductors. This would be required to provide some useful advice about suitable inductor types. However, at least for L4, a part with low DC resistance would be advised. I would highly recommend an iron core over an air core for L4!

If that is the scheme though I still have the problem of replacing the sm75-150 16h atc media speaker with an 8ohm one which I have made several changes and I don't think it sounds like the original one

You want to replace an SM75-150-16 with an SM75-150-8!? And you are worried about air core vs iron core? I am sorry if this sounds rude, but I'd recommend you to take a deep breath and think again about your priorities... changing the SM75 16 Ohm to an SM75 8 Ohm will require a major redesign of the xover. Why don't you just stick to the 16 Ohm version? The two SM75 versions are both equally "good".

Not posting here the schematic is a lazy approach IMHO.

Anyway, apart the problem of the non standard values, I’d use MKP caps and air cored coils for the mid and tweeter filters. For the bass, I’d definitely use a cored coil and an electrolytic cap (size and cost play a big role, and also DCR for the coil).

Ralf

Anyway, apart the problem of the non standard values, I’d use MKP caps and air cored coils for the mid and tweeter filters. For the bass, I’d definitely use a cored coil and an electrolytic cap (size and cost play a big role, and also DCR for the coil).

Ralf

crossover proac ebs

When I bought the speakers the media was bad and I could only get 8ohm so I still want to adapt it to the original crossover

When I bought the speakers the media was bad and I could only get 8ohm so I still want to adapt it to the original crossover

The voice coil units can be replaced quite easily. Just swap out your 8 Ohm version for a 16 Ohm unit. You can get the parts from ATC. Or you could try to convince me to check my stock of ATC SM75 for a pair of 16 Ohm units. I might be open for an exchange.

Anything around 1 mH and lower; air core is best; the heavier the wire gauge, the better. Once you go above 1 mH; and much higher in inductance; you should choose a cored type because the DC resistance starts to get too high with air core (many extra windings). The cored type increases the inductance without having to have so many extra wire turns as compared to air core. Again; I always choose the heaviest wire gauge in my intended budget. There are powdered type "Ferrite", "Permite", etc. cores other than just laminated steel so many options out there.

NOW; having said all of that, it is important to stay as close to the original X/O design when re-building an older unit. Sometimes, a smaller wire gauge on the inductor is used on purpose to help increase the Qt of a woofer (this is one example). If you stray too far from the original design, you may adversely affect the performance and quality. If an original crossover used electrolytic capacitors; I recommend changing to higher quality metalized poly', etc. UNLESS, the capacitance is very large then the cost goes way up and your goal is to stick to a tight budget...

NOW; having said all of that, it is important to stay as close to the original X/O design when re-building an older unit. Sometimes, a smaller wire gauge on the inductor is used on purpose to help increase the Qt of a woofer (this is one example). If you stray too far from the original design, you may adversely affect the performance and quality. If an original crossover used electrolytic capacitors; I recommend changing to higher quality metalized poly', etc. UNLESS, the capacitance is very large then the cost goes way up and your goal is to stick to a tight budget...

Ok, I just checked: I have a pair of SM75-150-SUPER 8 Ohm, but no STD 16 Ohm.

I would suggest you get in touch with ATC and explain that you need to change your 8 Ohm drivers to 16 Ohm. The ATC guys are quite helpful. They sent me a replacement voice-coil kit, which I used to repair a broken driver. The kits are available as 16 Ohm, so you could just use this for your driver.

I would suggest you get in touch with ATC and explain that you need to change your 8 Ohm drivers to 16 Ohm. The ATC guys are quite helpful. They sent me a replacement voice-coil kit, which I used to repair a broken driver. The kits are available as 16 Ohm, so you could just use this for your driver.

- Home

- Loudspeakers

- Multi-Way

- Crossover component