Hi there.

I am in the process of reutilizing a chassis and faceplate from an old MCS amplifier. I really like the faceplate, switches, etc...

I have already decided on using the ljm 12-2 amp, and have a pair of them and a power supply board that have been wanting a home. But...i really want to use this as a receiver, so I am trying to find a way to cram the rest of the stuff into the limited space left to me...

I would like to add:

Elliot preamp stuff - P05, P06, P99, P88.

and.. a bluetooth receiver module.

I was thinking about going "vertical" with the boards, or vertically stacking. But in any event, things would get crammed pretty close to the transformer.

Should I be shielding the transformer within the chassis? And, do i need to worry about the spacing between the boards?

Or - is this a scenario where it would be better to take all of the ESP stuff above, and combine into one or two large boards? (I would much rather buy the boards if possible).

Or - is this a recipe for disaster due to to some board-to-board field effects that I don't understand?

thanks!

I am in the process of reutilizing a chassis and faceplate from an old MCS amplifier. I really like the faceplate, switches, etc...

I have already decided on using the ljm 12-2 amp, and have a pair of them and a power supply board that have been wanting a home. But...i really want to use this as a receiver, so I am trying to find a way to cram the rest of the stuff into the limited space left to me...

I would like to add:

Elliot preamp stuff - P05, P06, P99, P88.

and.. a bluetooth receiver module.

I was thinking about going "vertical" with the boards, or vertically stacking. But in any event, things would get crammed pretty close to the transformer.

Should I be shielding the transformer within the chassis? And, do i need to worry about the spacing between the boards?

Or - is this a scenario where it would be better to take all of the ESP stuff above, and combine into one or two large boards? (I would much rather buy the boards if possible).

Or - is this a recipe for disaster due to to some board-to-board field effects that I don't understand?

thanks!

I really like building Rod's ESP designs- I have built the power supply and the RIAA phono pre-amp, and can attest they are most excellent.

What kind of transformer are you using? Toroidal, or E-I frame? Is the transformer already enclosed in a shield? I'm guessing it's going to be a pretty big one to really unleash the amplifiers.

Coupling effects should not be your first concern. That's a second order refinement that can be dealt with in many ways. Coupling sources are wherever there is high current variation- like the leads between the transformer and rectifier, the speaker outputs, traces on the amplifier PCB, etc. Coupling between high current variation and sensitive circuits is a concern, but shielding is a great option even in tight spaces, and good PCB placement to avoid the problem in the first place, if you can. All of the pre-amp stuff is going to be regulated and will live nicely next to each other even in a tight space.

My first concern is thermals. Those 12-2 amps need a lot of heat sinking and airflow. Do you have any pics of your chassis?

What kind of transformer are you using? Toroidal, or E-I frame? Is the transformer already enclosed in a shield? I'm guessing it's going to be a pretty big one to really unleash the amplifiers.

Coupling effects should not be your first concern. That's a second order refinement that can be dealt with in many ways. Coupling sources are wherever there is high current variation- like the leads between the transformer and rectifier, the speaker outputs, traces on the amplifier PCB, etc. Coupling between high current variation and sensitive circuits is a concern, but shielding is a great option even in tight spaces, and good PCB placement to avoid the problem in the first place, if you can. All of the pre-amp stuff is going to be regulated and will live nicely next to each other even in a tight space.

My first concern is thermals. Those 12-2 amps need a lot of heat sinking and airflow. Do you have any pics of your chassis?

I have done this before back in the day.

Finally, you have NO IDEA how many interconnecting wires you will need for such a project, its going to be a massive birds nest (at least for me!) connecting all those boards together and with the power supplies each needs as well.... and also connecting with the very nice front panel controls and/or lights/LEDs on your MCS unit, and the rear panel ins and outs.

Wires, and the amount of them, are going to be a lot! Try to plan this out and color code your wires.

Good luck, this sounds like a very nice project!

- plan everything out and place boards slowly one at a time to see how things sound, maybe preamp first, then amp?

- run the thing with just a few boards for awhile and then add more but do it slowly and make sure its all working.

Finally, you have NO IDEA how many interconnecting wires you will need for such a project, its going to be a massive birds nest (at least for me!) connecting all those boards together and with the power supplies each needs as well.... and also connecting with the very nice front panel controls and/or lights/LEDs on your MCS unit, and the rear panel ins and outs.

Wires, and the amount of them, are going to be a lot! Try to plan this out and color code your wires.

Good luck, this sounds like a very nice project!

Both you guys have provided much needed input, and very timely indeed.

wparks - I was about to take a photo to send you, and realized that, in fact, i was an idiot. I had the capacitors for the main PS about an inch from the amps heatsinks. whoops.

lgreen - you couldn't be more correct...especially since I appear to be trying to do everything at once. in one tiny box. I was logging in to reply to wparks, and then i saw your recent post...and decided to zig, and demote this chassis to a preamp only.

my thinking is to basically put my faith and trust in ESP P05, P06, P99,and maybe his P146 in this box...and then back to square 0 on the amp....but I think this makes intuitive sense. Then, I can play with the amps separately...and have a base to compare.

do you guys have an opinion on a bluetooth receiver module? good idea, bad idea, receommendation?

i should have time tomorrow to mock up a layout with cardboard.

thanks!

wparks - I was about to take a photo to send you, and realized that, in fact, i was an idiot. I had the capacitors for the main PS about an inch from the amps heatsinks. whoops.

lgreen - you couldn't be more correct...especially since I appear to be trying to do everything at once. in one tiny box. I was logging in to reply to wparks, and then i saw your recent post...and decided to zig, and demote this chassis to a preamp only.

my thinking is to basically put my faith and trust in ESP P05, P06, P99,and maybe his P146 in this box...and then back to square 0 on the amp....but I think this makes intuitive sense. Then, I can play with the amps separately...and have a base to compare.

do you guys have an opinion on a bluetooth receiver module? good idea, bad idea, receommendation?

i should have time tomorrow to mock up a layout with cardboard.

thanks!

and.. a bluetooth receiver module.

Your amp will benefit from shielding and using an existing enclosure is a good way to upcycle it. However, your BT receiver needs its antenna (or probably the whole module) be outside of it, otherwise you can't receive any BT signal.

i thought about that. My plan was to repurpose the front av2 input/output (~36mm square). I think this could provide a window for the antenna.

scratches not mine....but they appear to come out quite well with one of those magic eraser sponges. however...i am thinking about if it is a good idea to sand down the front so as to be able to relabel.

scratches not mine....but they appear to come out quite well with one of those magic eraser sponges. however...i am thinking about if it is a good idea to sand down the front so as to be able to relabel.

Attachments

Your thought of how it works doesn't apply to the physics. So, no, that won't work. But you are of course free to try it out yourself.

Hi ICG,

I am not sure what the physics concern you have would be? Can you please elaborate?

It is abosolutely true that the cheap, off the shelf options (https://www.data-alliance.net/antenna-2-4ghz-2dbi-directional-patch-adhesive-mount-w-rp-sma/) are a couple of mm too wide. But can't I enlarge the cutout in my faceplate?

Or, are you implying that I am incapable of soldering a ceramic chip antenna? (not a bad bet). But, while I haven't looked, these certainly fall within the 36x36 existing cutout (for example: https://www.taoglas.com/product/wlp-2450-25-4-a-02-2-4ghz-bluetooth-wlan-zigbee-patch-antenna-25mm/).

I don't see why either of these options would not work hidden behind a smoked polycarbonate window or other such facing material.

Am I missing something?

thx,

jeff

I am not sure what the physics concern you have would be? Can you please elaborate?

It is abosolutely true that the cheap, off the shelf options (https://www.data-alliance.net/antenna-2-4ghz-2dbi-directional-patch-adhesive-mount-w-rp-sma/) are a couple of mm too wide. But can't I enlarge the cutout in my faceplate?

Or, are you implying that I am incapable of soldering a ceramic chip antenna? (not a bad bet). But, while I haven't looked, these certainly fall within the 36x36 existing cutout (for example: https://www.taoglas.com/product/wlp-2450-25-4-a-02-2-4ghz-bluetooth-wlan-zigbee-patch-antenna-25mm/).

I don't see why either of these options would not work hidden behind a smoked polycarbonate window or other such facing material.

Am I missing something?

thx,

jeff

Hi ICG,

I am not sure what the physics concern you have would be? Can you please elaborate?

Sure. A metal enclosure blocks high frequency interference. That's good. However, BlueTooth is dependent on having communication on the 2,4 GHz band. If you have your BT receiver within the enclosure, it will not be able to communicate with any BT device. So that makes the good enclosure for the amp bad for the BT device. And if your amp is the device that's the BT receiver, you can't have any shielding of the amp at all because that's preventing it from its function.

Wouldn't putting the ground plane for the rf behind the window basically keep the seal "rf tight?"

Your concern is noted, but I don't see the same challenge as you. I feel that my metal work is at the level of creating effective chokes around any gaps I create.

However, I still think the look of the black "glass" acting as a receiver on my 70s face will make it look positively modern, indeed. Also like it came with an IR remote!

And I know I am not the first one down the path of moderinizing these old faces. If you are correct in that his is a physical impossibility, then I will feel very good when I have a solution to post.

Tomorrow I hope to mock up the board layout in cardboard before executing my PO.

Perhaps then you will see what my intent is, and then perhaps your concern will not be an issue.

Your concern is noted, but I don't see the same challenge as you. I feel that my metal work is at the level of creating effective chokes around any gaps I create.

However, I still think the look of the black "glass" acting as a receiver on my 70s face will make it look positively modern, indeed. Also like it came with an IR remote!

And I know I am not the first one down the path of moderinizing these old faces. If you are correct in that his is a physical impossibility, then I will feel very good when I have a solution to post.

Tomorrow I hope to mock up the board layout in cardboard before executing my PO.

Perhaps then you will see what my intent is, and then perhaps your concern will not be an issue.

I think you will realize that the BT receiver will not be impressed like I will because that's a skill I haven't mastered fully yet but a BT receiver doesn't have an eye for at all. However, the receiver does have a keen eye on metal shielding and that's why your BT will not work. That means, no matter how skilled you are at metal working, unless you put the BT receiver outside of the enclosure, you cannot expect it to work. Physics doesn't make exceptions for skilled craftsmanship, unfortunately. I'm a carpenter and I had to learn that too.

Of course a closed metal casing will make the BT stuff not functioning right. Faradays cage. Simple stuff.

What I see is some brands cut out a piece at the front and replace it for plastic. Or they use a display with enlarged window and place the BT modules antennas behind it. Or they simply use an external antenna (most effective and simplest!). Or they have the module at the back of the device covered by a plastic cover which I think is worse as then one can be sure that dreaded RF straying in on mains cables, interconnects etc. In short: there is a need for an opening in the metal casing for BT antennas signals when using an internal BT module with PCB antenna.

* BT is a pain if you like good sound without RF creeping everywhere polluting power supplies. It will take quite some time and energy to filter out that self-inflicted RF (if you manage at all). One trades quality for convenience.

What I see is some brands cut out a piece at the front and replace it for plastic. Or they use a display with enlarged window and place the BT modules antennas behind it. Or they simply use an external antenna (most effective and simplest!). Or they have the module at the back of the device covered by a plastic cover which I think is worse as then one can be sure that dreaded RF straying in on mains cables, interconnects etc. In short: there is a need for an opening in the metal casing for BT antennas signals when using an internal BT module with PCB antenna.

* BT is a pain if you like good sound without RF creeping everywhere polluting power supplies. It will take quite some time and energy to filter out that self-inflicted RF (if you manage at all). One trades quality for convenience.

Last edited:

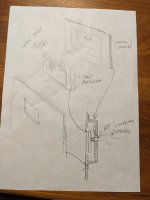

Is your concern from the BT module itself or the antenna portion. today got away from me, and so no cardboard model, but I made a sketch for my intention of the panel front. I still need to hear back from TE regarding my potting strategy. their antennas are not the cheapest...but it comes with a skilled engineer on the other end ;-).

the idea is is simple to me, and i have used this in other scenarios at higher frequencies and much higher power. i don't see leakage through this, and my intent was to use a shielded antenna cable to the board. in all honesty, i had not thought about that one junction on the board as creating an issue. and this conversation did make me consider that.

I do appreciate that maybe you are being "grounded in reality". But you are right jean-paul, this is a pain. But so is needing to match jfets. people still do it. true, not for bluetooth quality.

in my case, this is not a production model, nor intended to be. I have been putting off building a system for far too long. this is supposed to be fun!

i suspect this is something that is of interest to one, maybe two or three folks. but like i said. i think it would look cool. and so, let it be my windmill to tilt at.

Helpful suggestions would be welcome. things like "you really need a separate power supply line feeding the data side". (I don't know, perhaps his is true). Or, more likely - "you should cage that sucker entirely and feed a signal out through a 1:1 stage". something with a reason behind it. I don't know, haven't built anything yet. And...the time I should have spent building the cardboard layout (so i can buy the boards...)..well, I spent that thinking about how to respond, and whether to.

Note that in my design, the potting material is yet to be confirmed, and the formed back will be simple bent steel. In theory, the BT module could be buried under this as well, but I would rather not. I had started thinking that way, but would like to keep this separate. Even if it mean needing to shield the receiver module.

I don't show the use of copper scrubby, which may or may not be needed as a gasket depending on my bending skills.

For you guys who appear to be not on the BT bandwagon, I would ask that maybe keep an open mind, and maybe with a little more positive help my project can prove you wrong. If you want to be really helpful, you could recommend a BT receiver module. pref one with a built in antenna socket.

I am a ways away from the build. And I do think that this conversation needs a conclusion of some sorts. While it was never in my plans, I do have access to a source meter and a scope. I have not thought about what testing would be needed to be done to answer your concerns. If you would like to propose something reasonable that might settle the issue, I would be more than happy to consider.

the idea is is simple to me, and i have used this in other scenarios at higher frequencies and much higher power. i don't see leakage through this, and my intent was to use a shielded antenna cable to the board. in all honesty, i had not thought about that one junction on the board as creating an issue. and this conversation did make me consider that.

I do appreciate that maybe you are being "grounded in reality". But you are right jean-paul, this is a pain. But so is needing to match jfets. people still do it. true, not for bluetooth quality.

in my case, this is not a production model, nor intended to be. I have been putting off building a system for far too long. this is supposed to be fun!

i suspect this is something that is of interest to one, maybe two or three folks. but like i said. i think it would look cool. and so, let it be my windmill to tilt at.

Helpful suggestions would be welcome. things like "you really need a separate power supply line feeding the data side". (I don't know, perhaps his is true). Or, more likely - "you should cage that sucker entirely and feed a signal out through a 1:1 stage". something with a reason behind it. I don't know, haven't built anything yet. And...the time I should have spent building the cardboard layout (so i can buy the boards...)..well, I spent that thinking about how to respond, and whether to.

Note that in my design, the potting material is yet to be confirmed, and the formed back will be simple bent steel. In theory, the BT module could be buried under this as well, but I would rather not. I had started thinking that way, but would like to keep this separate. Even if it mean needing to shield the receiver module.

I don't show the use of copper scrubby, which may or may not be needed as a gasket depending on my bending skills.

For you guys who appear to be not on the BT bandwagon, I would ask that maybe keep an open mind, and maybe with a little more positive help my project can prove you wrong. If you want to be really helpful, you could recommend a BT receiver module. pref one with a built in antenna socket.

I am a ways away from the build. And I do think that this conversation needs a conclusion of some sorts. While it was never in my plans, I do have access to a source meter and a scope. I have not thought about what testing would be needed to be done to answer your concerns. If you would like to propose something reasonable that might settle the issue, I would be more than happy to consider.

Attachments

I think your idea, putting the BT antenna behind the door for the tape connectors is worth a try. Just fix the door and put the antenna behind it, using some thin tape. If it works you can permanently glue it all up. Maybe try to do that with a complete BT module and put a shield behind it. I have some small, 10$ things that work remarkable well. Just got to find the antenna side by experimenting or opening it up.

I have found BT working in the most stupid situations and making problems in seemingly perfect locations. Same with BT induced noise problems. For our kind of hobby developments try and error are the only way to go with certain things, as stupid it may seem.

I'm usually the planer type of guy, not the "let's try it, maybe it will work" happy idiot. With HF radiation in the GHz region experimenting will be the only way to get truth. With HF even a few centimeter can make a the difference between OK and screw up.

I would get a complete BT module and put it on the rear panel, as far away as possible from connectors. So you only run NF signal and power inside the amp. Cheapest option and if not working, you still got a useable BT for some other task.

PS post #3 is most valueable, that is how I ususally do it too. Fix one problem at a time.

I have found BT working in the most stupid situations and making problems in seemingly perfect locations. Same with BT induced noise problems. For our kind of hobby developments try and error are the only way to go with certain things, as stupid it may seem.

I'm usually the planer type of guy, not the "let's try it, maybe it will work" happy idiot. With HF radiation in the GHz region experimenting will be the only way to get truth. With HF even a few centimeter can make a the difference between OK and screw up.

I would get a complete BT module and put it on the rear panel, as far away as possible from connectors. So you only run NF signal and power inside the amp. Cheapest option and if not working, you still got a useable BT for some other task.

PS post #3 is most valueable, that is how I ususally do it too. Fix one problem at a time.

You want helpful comments and got them I think? There is no escaping electrical laws though. And yes, having clean power supplies is a challenge when jumping the BT bandwagon as you put a RF transmitter in or near analog circuits. A bit like adding a bit of gasoline to the milk of your cereal and then trying to get rid of the gasoline taste. I even notice that the sequel how stuff is stacked makes a difference. If the device with BT is on the upper side of the stack and all devices have steel casings things can go reasonably well. If you keep an open mind you will see that many things are invented to make money and not with quality in mind.

https://en.wikipedia.org/wiki/Faraday_cage

https://en.wikipedia.org/wiki/Faraday_cage

Last edited:

sorry for the reply. i very much got side tracked...and thanks for the input.

my current plan is to have the antenna and receiver up front in the cutout in the aluminum face (shielded from the inside, and directionally outward. most likely candidate for the antenna is (https://www.ebay.com/itm/1959593468...nLVaREWi4cZwuiKNNSOmX7ZzOEUhZ6N0i1L-UN1xNUfZk ), based on the fact it is cheap, easy, and the right size. This will feed the receiver (also within the shielded front), and then I2S back into the box. So..the only thing head back into the chassis proper is the I2S signal, and the 5v or so line feeding the receiver.

It was specifically the bluetooth I2S dac that I was hoping to get some input on. Though I can tell by the conversation that the bluetooth signal is not something to take lightly.

I am still vacillating on the preamp circuitry, because I really want to have working treble and bass knobs - and so I haven't ordered the stuff yet. but hopefully before the end of the week.

my current plan is to have the antenna and receiver up front in the cutout in the aluminum face (shielded from the inside, and directionally outward. most likely candidate for the antenna is (https://www.ebay.com/itm/1959593468...nLVaREWi4cZwuiKNNSOmX7ZzOEUhZ6N0i1L-UN1xNUfZk ), based on the fact it is cheap, easy, and the right size. This will feed the receiver (also within the shielded front), and then I2S back into the box. So..the only thing head back into the chassis proper is the I2S signal, and the 5v or so line feeding the receiver.

It was specifically the bluetooth I2S dac that I was hoping to get some input on. Though I can tell by the conversation that the bluetooth signal is not something to take lightly.

I am still vacillating on the preamp circuitry, because I really want to have working treble and bass knobs - and so I haven't ordered the stuff yet. but hopefully before the end of the week.

Place your Bluetooth antenna under the amp chassis with two sided tape. Simple, you just need a small hole for the coax. It is out of sight and in open air.

FWIW - I got impatient, and ordered this (https://www.aliexpress.com/item/1005005455956921.html), which should let me avoid the need to learn how to deal with i2S. So very much like the approach Nico Ras has suggested, except will be using a different antenna.

- Home

- Design & Build

- Construction Tips

- cramming boards into an existing chassis