surely some mistake in the circuit? MPSA56 and MJE350 positions swapped?

In circuits like this (asymmetrical) I have seen thermal oscillations cause DC bias drifts. Plastic transistors are worse than metal cans (longer time constants) but metal cans need isolating from each other when using a common heat clip. If circuit behaved better in the past then I would suspect the electroltyics.

I'm now convinced that this is a design error as all of the Classe amplifiers from the era show the same positions of the MPSA56 and MJE350. I have confirmed that this is the case on my DR-25 and the schematic MATCHES the actual circuit. More information on this confusing mistake can be found here:

http://www.diyaudio.com/forums/solid-state/278883-classe-dr-25-25-repair.html

I have still not looked at changing these devices around on my amp but will investigate it at some point soon.

Well that doesn't look trivial even for a professional! It would be too convenient if both transistors used the same package! But no.

Sent from my GT-I9505 using Tapatalk

Sent from my GT-I9505 using Tapatalk

So this 'thermal oscillation' would be produced purely by a circuit flaw and has no causal or contributory effect from physical proximity of a sensitive component to a heat emitting component? Is that it?

Sent from my GT-I9505 using Tapatalk

Sent from my GT-I9505 using Tapatalk

So this 'thermal oscillation' would be produced purely by a circuit flaw and has no causal or contributory effect from physical proximity of a sensitive component to a heat emitting component? Is that it?

Sent from my GT-I9505 using Tapatalk

Does the DC offset bounce around the same with the lid on the amp and it away from any air flow sources?

I'll check and let you know, but 3 readings per second on the DMM seems a bit quick and could only be equal or worse with the lid on, don't you think?

Sent from my GT-I9505 using Tapatalk

Sent from my GT-I9505 using Tapatalk

I'll check and let you know, but 3 readings per second on the DMM seems a bit quick and could only be equal or worse with the lid on, don't you think?

Sent from my GT-I9505 using Tapatalk

The input stage is very susceptible to airflow and can cause fluctuation in the DC offset. I am going to bet it will be more stable with the lid on.

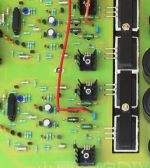

Ok. Will check. Also, I notice scorch marks on the Wimas next to the MJE340's, and the MPSA06/56 are next to the MJE350's. I'm wondering if there is any mileage in exploring larger heatsinks, or even slightly bending them away from each other. ...Or that could end in grief with broken leads?

I have also seen offset shift due to RF getting rectified, coming in on the inputs or the loudspeaker outputs.

Cellphone/cordless phone/WiFi/AM/FM the RF gets in. If the offset problem suddenly disappears then reappears, when you change cabling or someone's phone is nearby etc. It can be periodic too.

TI sboa128a.pdf

Analog Devices MT-096.pdf

Input filter prevents instrumentation-amp RF-rectification errors EDN

Cellphone/cordless phone/WiFi/AM/FM the RF gets in. If the offset problem suddenly disappears then reappears, when you change cabling or someone's phone is nearby etc. It can be periodic too.

TI sboa128a.pdf

Analog Devices MT-096.pdf

Input filter prevents instrumentation-amp RF-rectification errors EDN

If those transistors are swapped would it then not make sense to move the heatsink to the other transistor, the one that does the heavy lifting? That in itself could fix it. As I see it, the wrong transistor is heatsunk and the non-heatsunk one gets hot.

Can you check the temp of those transistors, just touching to see if tehre is a large difference, and to find which one is actually getting hot?

Jan

Can you check the temp of those transistors, just touching to see if tehre is a large difference, and to find which one is actually getting hot?

Jan

So this 'thermal oscillation' would be produced purely by a circuit flaw

That is the real question then, isn't it? Whether the amp left the factory trimmed down to the impossibly low 1mV as the service manual states, or it was always a bit shaky.

Just to confirm: you are testing the offset with the input shorted, right?

The problem with MPSA56/06 are that they are TO-92 package. I can see that a heatsink is made for these, but not so common perhaps? They don't seem hot. The other heatsink is for a TO-126 and completely incompatible.If those transistors are swapped would it then not make sense to move the heatsink to the other transistor, the one that does the heavy lifting? That in itself could fix it. As I see it, the wrong transistor is heatsunk and the non-heatsunk one gets hot.

Can you check the temp of those transistors, just touching to see if tehre is a large difference, and to find which one is actually getting hot?

Though I'd not come across the shorting recommendation for DC Offset testing, it made no difference here.That is the real question then, isn't it? Whether the amp left the factory trimmed down to the impossibly low 1mV as the service manual states, or it was always a bit shaky.

Just to confirm: you are testing the offset with the input shorted, right?

Well that was interesting and a bigger difference than expected, by putting the lid on, per Ungie's recommend, settled things right down. I was able to get the DC Offset down to 0 +/-1.5mV. But only measuring with the lid on. It's still bouncing constantly but the swings are much smaller. It's a little fiddly lifting the lid to adjust and setting it back down to wait a few minutes each time and measure, but am feeling a bit more comfortable with my readings.The input stage is very susceptible to airflow and can cause fluctuation in the DC offset. I am going to bet it will be more stable with the lid on.

Another storm in a teacup 🙄

Sorry.

It is interesting to me that the Offset readings are very different (20-40mV) with the lid off than on, not to mention the bouncing.

Also it was helpful to me that the Classe Audio circuit flaw was identified, and the voltage variations and heat issues from the schematic. While the Model 70 schematic says 10,000uF/63v, the cans are 75v and the rail is 58.5v rather than 44.5v spec'd. I already knew this, but the link in to the Model 25 thread connected some dots for me.

Sorry you had to come along for the ride.

Sorry.

It is interesting to me that the Offset readings are very different (20-40mV) with the lid off than on, not to mention the bouncing.

You have clearly not built a Paradise phono preamp then 😀

Admittedly it has a much better reason for this behaviour as the dc gain is dramatically different.

Anyway, it has been and interesting thread for me.

The "problem" is obviously very common and if you look at the LTP of high priced products such as a late model Naim amplifier, you find the old design has been given a cute little plastic hat to reduce the effects of thermal drift and fluctuation of the offset. Really, when the spec is only +/- 30 mV, it seems redundant but there are those who believe that there is something important about having an offset that is stable and always reads zero to the limits of their DMM. 🙄

The black objects on the left side are the covers on each channel's LTP. I dare say anything similar that fits securely over your transistors, such as an HDMI or USB plug cover, will do fine.

The black objects on the left side are the covers on each channel's LTP. I dare say anything similar that fits securely over your transistors, such as an HDMI or USB plug cover, will do fine.

Attachments

Caps spec'd around trimpot?

A question about the caps next to the offset trimpot:

Could someone look at the circuit attached and tell me which is more helpful at C105, an electrolytic at 100uF/25v or a polyfilm at 100nf/250v?

C105 in the schematic is 100uF/25v, but on the board is a Wima film 100nf/250v (like C115). Given Classe Audio's history, either could easily be wrong.

I changed out the trimpots and now I'm able to adjust one channel somewhat predictably, but the other channel seems pretty resistant to adjustment -- so suspecting the caps on either side of the trimpot.

A question about the caps next to the offset trimpot:

Could someone look at the circuit attached and tell me which is more helpful at C105, an electrolytic at 100uF/25v or a polyfilm at 100nf/250v?

C105 in the schematic is 100uF/25v, but on the board is a Wima film 100nf/250v (like C115). Given Classe Audio's history, either could easily be wrong.

I changed out the trimpots and now I'm able to adjust one channel somewhat predictably, but the other channel seems pretty resistant to adjustment -- so suspecting the caps on either side of the trimpot.

Attachments

C115 is supply rail decoupling. Don't change it.

C105 is a stabilising cap on the cascode voltage. Don't change it.

Who invented the new values for C108, C109 & C110? They don't have a clue, revert back to Classe original values.

C105 is a stabilising cap on the cascode voltage. Don't change it.

Who invented the new values for C108, C109 & C110? They don't have a clue, revert back to Classe original values.

OK, on the C105/C115 -- leave at film 100nF 250v and replace with like.

The C108, C109, & C110 were misreadings 7 years back of what was written on the caps. Don't know what I was reading back then, maybe needed reading glasses and hadn't realised it yet!

Thank you

The C108, C109, & C110 were misreadings 7 years back of what was written on the caps. Don't know what I was reading back then, maybe needed reading glasses and hadn't realised it yet!

Thank you

The thread is approaching the one month mark now, and the owner of the amp hasn't tried any of the dozen hypothetical fixes that were suggested. 3 times per second isn't really specific and might even be your meter's update rate. A strange symptom does not always mean a faulty part, but rather just the right combination of part tolerances. In that case changing any of the parts will change the symptom in some way. Take measurements, try what seems logical, and keep a notebook.

RA

RA

The thread is approaching the one month mark now, and the owner of the amp hasn't tried any of the dozen hypothetical fixes that were suggested. 3 times per second isn't really specific and might even be your meter's update rate. A strange symptom does not always mean a faulty part, but rather just the right combination of part tolerances. In that case changing any of the parts will change the symptom in some way. Take measurements, try what seems logical, and keep a notebook.

RA

I'm rather confused why you make this assertion. I can't find a dozen hypothetical fixes suggested. And the ones suggested were all acted upon, addressed appropriately, or warned against by others. Notes are being taken, and the previous question was asking for what was logical on a particular decision.

So I am left asking what you read in this thread the supports the above comments, or makes them helpful?

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Constantly bouncing DC Offset?