I have been thinking about a replacement for the high frequency section of our horn sound system. Currently we use 3 *40 degree 8+1” coaxial horns horizontally arrayed >400Hz (the top horn of this orbit top).

We already don’t use the lower folded horn instead using 15” midbass horns 100-400Hz: https://www.diyaudio.com/community/threads/mega-midbass-straight-horn-139db.349105/

Then above this I have been designing a horn for M200 midrange compression drivers ( https://www.diyaudio.com/community/...per-scripts-and-m200-fun.385493/#post-7003214 ). My plans have moved forward a little since this thread and I now plan on making this a dual driver horn covering up to 3kHz. I would like to mount a vertically arrayed tweeter array coaxial to this horn (at the mouth). This would be something like the Void Incubus which appears to use a constant curvature array composed of line array waveguides:

My aim would be 90 degree horizontal dispersion and 4-6 elements vertical so 10-15 degree vertical . However when I look at the data for a line array waveguide like the B&C ME102 I see that the horizontal is very wide and the vertical is not displaying constant directivity behavior (although is B&C quoting -12dB contour rather than -6dB?):

The horizontal dispersion of the B&C ME102 depends on the horn to which the ME102 waveguide is attached. The graph in the data sheet appears to be taken with a 90 degrees horn.I would like to mount a vertically arrayed tweeter array coaxial to this horn (at the mouth). This would be something like the Void Incubus which appears to use a constant curvature array composed of line array waveguides:

The given data appears to be the directivity of a single unit. The vertical dispersion will change when used in an array, as stated in the data sheet:My aim would be 90 degree horizontal dispersion and 4-6 elements vertical so 10-15 degree vertical . However when I look at the data for a line array waveguide like the B&C ME102 I see that the horizontal is very wide and the vertical is not displaying constant directivity behavior (although is B&C quoting -12dB contour rather than -6dB?):

B&C ME102 data sheet said:Vertical coverage depends on configuration

Last edited:

It hadn't occurred to me that the ME102 was intended to be used with another horn, is it best thought of as a device that changes the compresion driver throat into a plane wave orginating from a rectangular throat?The horizontal dispersion of the B&C ME102 depends on the horn to which the ME102 waveguide is attached. The graph in the data sheet appears to be taken with a 90 degrees horn.

Yes 🙂

Horizontally the ME102 throat is so small that it has no directivity on its own, at least up to 5 kHz.

Vertically the wavefront is (designed to be) either flat or slightly curved, to meet with the wavefront of the adjacent ME102.

Horizontally the ME102 throat is so small that it has no directivity on its own, at least up to 5 kHz.

Vertically the wavefront is (designed to be) either flat or slightly curved, to meet with the wavefront of the adjacent ME102.

https://www.bcspeakers.com/resources/suggested-designs/

B&C now have some suggested extension horns for their line array waveguides, as you would expect from the above discussion they are quite basic conical horns.

B&C now have some suggested extension horns for their line array waveguides, as you would expect from the above discussion they are quite basic conical horns.

BMS 5530 is smaller at 72mm.

Probably best to stick with commercial waveguides for best HF performance.

I've thought about using a stack of BMS drivers on truncated B&C ME10's. It would still have a lot of comb filtering at high frequencies compared to the plane wave devices.

Probably best to stick with commercial waveguides for best HF performance.

I've thought about using a stack of BMS drivers on truncated B&C ME10's. It would still have a lot of comb filtering at high frequencies compared to the plane wave devices.

Your post made me recall DSL switched from Eminence to a Faital Pro HF driver in the J7-95 a few years ago.I don't know if this driver is new but I haven't seen it before HF106 it looks ideal for array applications as its very compact. I should probobly resist the temptation to design my own hf waveguides for it to achive higher packing density...

The J7-95 employs 8 HF drivers with narrow conical horn throats deployed in a vertical curvature coupled to a two-part conical horn, all parts could be cut with standard woodworking tools.

EAW use a similar format of horn in their Anya and Anna line arrays, though rather than using constant curvature, they use individual amplification and DSP for each driver pair in the flat front array to describe the vertical coverage desired for the particular venue.

EAW's approach is quite expensive and the horn parts difficult to DIY in wood.

DSL's approach would be fairly simple, and avoids all the bendy pathways the "line array optimized" waveguide couplers employ, far more "straight ahead" than the Paraline devices in previous "J" (Jericho Horn) series.

Art

found some more pictures of the ANYAs horns. It looks like the HF horns are veritcaly stacked and have no vertical expansion which makes sense if you want to make a steerable array. However this does mean however to get a reasonable array length an obscene number of compresion drivers is requried. 22 in the case of the ANYA.

interesting internal structure pic of the LA-WG14. Looks to be a conical horn with pins to alter the effective density of the medium to delay the wavefront more at the middle.

I've been thinking of building a constant curvature array myself. Seems like the best compression driver waveguide would radiate at the desired radius of curvature for the whole array. I havent tried yet but want to buy a few cheap waveguides and try to measure the wavefront along the length of the exit to see how "curved" it is over its bandwidth.

In the EAW and DSL approach, it appears that the drivers are alternating directions while stacked. If the J7 is 90x50 with 8 HF drivers and the drivers are stacked in alternating directions, how are they coupling if they point in different directions? I guess what I'm asking is what would it take to build a HF horn section that accomplishes coupling between that many stacked drivers without the comb filtering that would happen with stacked line array waveguides?Your post made me recall DSL switched from Eminence to a Faital Pro HF driver in the J7-95 a few years ago.View attachment 1100645

The J7-95 employs 8 HF drivers with narrow conical horn throats deployed in a vertical curvature coupled to a two-part conical horn, all parts could be cut with standard woodworking tools.

EAW use a similar format of horn in their Anya and Anna line arrays, though rather than using constant curvature, they use individual amplification and DSP for each driver pair in the flat front array to describe the vertical coverage desired for the particular venue.

View attachment 1100646

EAW's approach is quite expensive and the horn parts difficult to DIY in wood.

DSL's approach would be fairly simple, and avoids all the bendy pathways the "line array optimized" waveguide couplers employ, far more "straight ahead" than the Paraline devices in previous "J" (Jericho Horn) series.

Art

Or would there not be much comb filtering with the Void design above since there's little to no overlap?

So if I'm understanding correctly, the goal is for the sound to reach the top and bottom of the horn at the same time as the center. And the medium in the middle helps that happen by bending the waves in the center before the exit to give them a longer path length. Would that be correct?View attachment 1115770

interesting internal structure pic of the LA-WG14. Looks to be a conical horn with pins to alter the effective density of the medium to delay the wavefront more at the middle.

yes this seems like an intuative way of thinking about it and the pins are elongated in the direction of propagation so perhaps their distribution can be computed by working out the effective path length increase of a pin?So if I'm understanding correctly, the goal is for the sound to reach the top and bottom of the horn at the same time as the center. And the medium in the middle helps that happen by bending the waves in the center before the exit to give them a longer path length. Would that be correct?

yes perhaps a pin based waveguide could be 3D printed to make this curve.I've been thinking of building a constant curvature array myself. Seems like the best compression driver waveguide would radiate at the desired radius of curvature for the whole array. I havent tried yet but want to buy a few cheap waveguides and try to measure the wavefront along the length of the exit to see how "curved" it is over its bandwidth.

I think with the left right pointing on the J7 the effect is minor so it can be assumed they are 'straight on'. comb filtering hmm not so sure, at the higher frequency range of the waveguides there is effectivly no overlap, also how audiable is extemely high frequency comb filtering as at some point the notches must be less than the ears critical bandwidth.

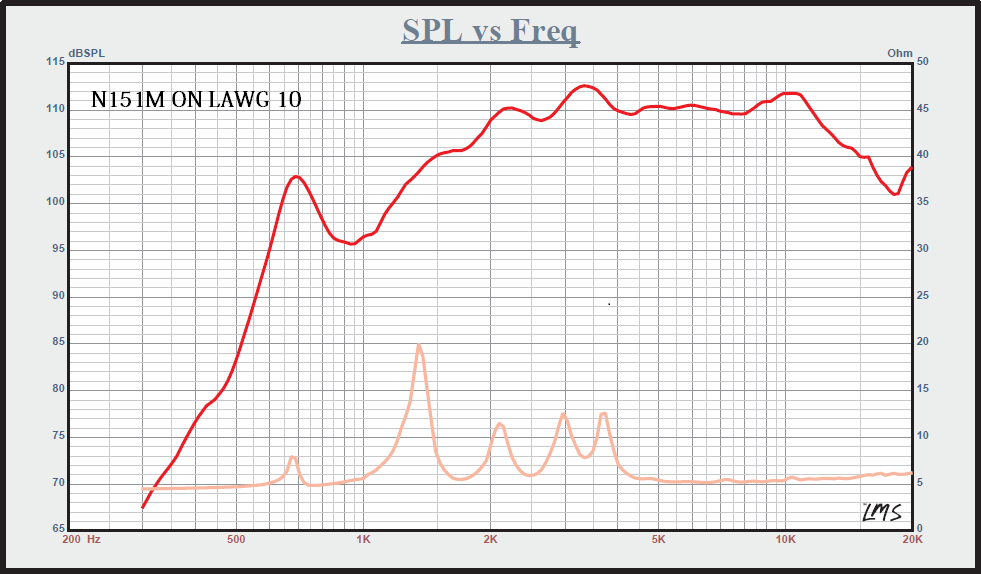

To speed things along I ordered 10 of '2020 Tweeter Line Array Speaker Horn Wave Guide Throat for Home Theater Audio Device' this appears to be a clone of the B&C ME102, the external dimensions match the B&C drawing. This also looks like the Eminence LA-WG10 which is OEM sourced, the frequency response plot posted looks promising:

Last edited:

To speed things along I ordered 10 of '2020 Tweeter Line Array Speaker Horn Wave Guide Throat for Home Theater Audio Device' this appears to be a clone of the B&C ME102, the external dimensions match the B&C drawing. This also looks like the Eminence LA-WG10 which is OEM sourced, the frequency response plot posted looks promising:

View attachment 1145212

Even cheaper here, just in case you need more https://www.aliexpress.us/item/3256...tewayAdapt=glo2usa4itemAdapt&_randl_shipto=US

To speed things along I ordered 10 of '2020 Tweeter Line Array Speaker Horn Wave Guide Throat for Home Theater Audio Device' this appears to be a clone of the B&C ME102, the external dimensions match the B&C drawing. This also looks like the Eminence LA-WG10 which is OEM sourced, the frequency response plot posted looks promising:

View attachment 1145212

What size is the throat hole on the knock-off waveguide? 1" or 1.4"? B&C says the ME102 is 1" but Eminence says theirs is 1.4"

These recent updates on your end have actually reignited my DIY interest in the J7 & J8 designs. Best I can tell, there is a short horn for each driver. Given that they're now using the Faital HF108, that gives a rough estimate of a 3.5" mouth if they're being packed as tight as possible. This would track with the straight-on pic of the J7 where you can see the circular driver throat down one of the horns. In that image, you can see that the driver is in the center of what appears to be a short horn.View attachment 1100724

found some more pictures of the ANYAs horns. It looks like the HF horns are veritcaly stacked and have no vertical expansion which makes sense if you want to make a steerable array. However this does mean however to get a reasonable array length an obscene number of compresion drivers is requried. 22 in the case of the ANYA.

I had previously thought that the J7 HF horns must have a sort of bend to them in order to fit properly, and that made sense with the size and arrangement of the BMS drivers. However, with the Faitals, that bend may not be needed anymore and I'm not positive, but I don't think it exists at all in the new versions or in the J8. I believe these are exponential horns that end up at 90°, but with a gradual flare rate that doesn't begin the 90° until hitting the main horn that the rest of the drivers feed into.

Horizontally, that would mean an 11.25° flare, then 22.5°, and then 45° when it hits the main horn. That would appear to be what's going on just from looking at it. Not too hard to build knowing the dimensions of the HF108. So I built one out of cardboard tonight.

The only thing I'm not positive on is the vertical expansion. Numbering the drivers 1 through 8 top-to-bottom, one could assume that the space between the center two drivers (4 & 5) is a 0° plane. If it is 0°, then the other half could be 6.25°. if each horn has 0° on one end and 6.25° on the next, then four from center would leave 25° on each side, giving it 50° total, hence the 50° coverage pattern of the J7. The only problem is that it doesn't "look" like that's what's going on here. It looks like there is an equal expansion rate for both sides of the vertical plane, which would lead to overlap between the horns. That may not even be noticable for such a short horn, so I'm not sure that it matters much.

The other problem with the 0° & 6.25° horn size is that the drivers may end up running into each other with the curve needed to line up one horn's 0° against the previous horn's 6.25° side. Gotta build another cardboard model to see what's going on.

Curiously, after seeing that EAW uses 15" drivers, I'm wondering why Danley went with 10" LF drivers on the J7. Stacking three 6.5" drivers would even leave room for a single 18" to match in size and driver compliment further down the horn path. You'd need a much larger slot to get those frequencies out though.

- Home

- Live Sound

- PA Systems

- Constant curvature tweeter array