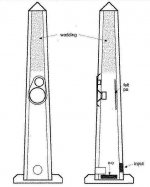

I am currently building a pair of conical speakers (see picture link). They are about 60 cm tall (24 inch) and 30 cm in diameter (12 in).

I am going to use SEAS elements, a 5 inch and a 3/4 inch tweeter.

The cones are made out of 24 pieces of wood (maple) glued together.

I have put together the first cone and I'm right now in the process of deciding how the speaker elements are going to be oriented. Far up? close together? far down? in the middle?

Also I am trying to figure out how I should deal with potential resonance- how to eliminate potential problems due to the fact that they are made of wood and not some kind of board.

Does anyone have any good ideas?

A picture of the speaker

Thanks a lot!!!

I am going to use SEAS elements, a 5 inch and a 3/4 inch tweeter.

The cones are made out of 24 pieces of wood (maple) glued together.

I have put together the first cone and I'm right now in the process of deciding how the speaker elements are going to be oriented. Far up? close together? far down? in the middle?

Also I am trying to figure out how I should deal with potential resonance- how to eliminate potential problems due to the fact that they are made of wood and not some kind of board.

Does anyone have any good ideas?

A picture of the speaker

Thanks a lot!!!

The design of your speakers is stunning. What an excellent concept.

Worried about the speaker being made of wood? Almost all good speakers used to be made of wood. MDF or particle board came later and saves money, and yes, it is somewhat denser, but you can still make a usable enclosure out of hardwood. In your case, the shape both strengthens the enclosure and cuts way down on internal resonances.

A conical enclosure made of wood is much stronger than a box made of MDF if the material is of comparable thickness. How thick are the walls of the cone going to be?

If you have the woodworking skills to execute that visually brilliant and acoustically outstanding design, my hat is off to you.

Go to it!

Worried about the speaker being made of wood? Almost all good speakers used to be made of wood. MDF or particle board came later and saves money, and yes, it is somewhat denser, but you can still make a usable enclosure out of hardwood. In your case, the shape both strengthens the enclosure and cuts way down on internal resonances.

A conical enclosure made of wood is much stronger than a box made of MDF if the material is of comparable thickness. How thick are the walls of the cone going to be?

If you have the woodworking skills to execute that visually brilliant and acoustically outstanding design, my hat is off to you.

Go to it!

A while back i did some render/sketches of a conical voigt pipe throwing it out as a thot experiment.

Well, a fellow in Australia decided to build them. he is using the stacks of mdf slices method of construction -- i am attempting to get some pics of his progress.

dave

Well, a fellow in Australia decided to build them. he is using the stacks of mdf slices method of construction -- i am attempting to get some pics of his progress.

dave

Hi There, I'm the madman from Oz

Hi Dave and other !

yep I'm the dumby who said he would build a 6ft tal conical tapered pipe.

Anyway, in case you didn't know, I nearly dislodged a finger while using a hole saw *different project), and I am really only just getting back to things again now. The "Conehead"s are at about 3' tall at the moment and progressing slowly.

I have access to a digital camera sometimes, so I will see if I can do something about pics for you real soon I hope !!!

To the question in hand, to avoid lobing problems through the cross-over region you must keep the mid/woof and tweeter as close together as possible.

Hi Dave and other !

yep I'm the dumby who said he would build a 6ft tal conical tapered pipe.

Anyway, in case you didn't know, I nearly dislodged a finger while using a hole saw *different project), and I am really only just getting back to things again now. The "Conehead"s are at about 3' tall at the moment and progressing slowly.

I have access to a digital camera sometimes, so I will see if I can do something about pics for you real soon I hope !!!

To the question in hand, to avoid lobing problems through the cross-over region you must keep the mid/woof and tweeter as close together as possible.

Attachments

Progress so far:

As of right now I have managed to put one of the speakercones together.

The material thickness is about 2 cm (4/5 in).

My next quest is to trim the top and bottom and build the the "lid"-part on top and the botton. I'll probably use MFD for the bottom since it won't be seen anyway and it's quite stiff.

Still would like to know how to position the elements.

I have also added a picture from the progress in my work...

The elements in the pictures "mockups", just a black sheat of paper in order to try out how different positons visually.

As of right now I have managed to put one of the speakercones together.

The material thickness is about 2 cm (4/5 in).

My next quest is to trim the top and bottom and build the the "lid"-part on top and the botton. I'll probably use MFD for the bottom since it won't be seen anyway and it's quite stiff.

Still would like to know how to position the elements.

I have also added a picture from the progress in my work...

The elements in the pictures "mockups", just a black sheat of paper in order to try out how different positons visually.

Attachments

sorry didn't see the reply about position of the elements. Makes sense to put them close together? Is 2 inches to far apart?

drivers and wadding

The pic above still has the drivers too far apart IMO. Lift the woof an inch or so then lower the tweet to as close as you can get it. Which tweet are you using btw. A beefy tweet with a lower Fs, will allow you to cross slightly lower and maybe use a bit more separation of the woof and tweet if it is necessary for construction purposes.

Now the wadding. This is a normal loudspeaker. is it vented btw?

You will need to treat it as normal and apply wadding to all interior faces. The internal standing waves in this should be fairly well dispersed, so the main purpose of the wadding will be to dampen any cabinet resonances. I would suggest a layer of carpet foam (or similar) glued to the inside then a thin layer of poly wadding. Oh, and if its vented, keep the wadding away from the inner end vent opening by at least 4 if you can.

(the tapered pipe is a different fish completely, which is why the wadding is only at he top in the diagram above)

Have fun !!

The pic above still has the drivers too far apart IMO. Lift the woof an inch or so then lower the tweet to as close as you can get it. Which tweet are you using btw. A beefy tweet with a lower Fs, will allow you to cross slightly lower and maybe use a bit more separation of the woof and tweet if it is necessary for construction purposes.

Now the wadding. This is a normal loudspeaker. is it vented btw?

You will need to treat it as normal and apply wadding to all interior faces. The internal standing waves in this should be fairly well dispersed, so the main purpose of the wadding will be to dampen any cabinet resonances. I would suggest a layer of carpet foam (or similar) glued to the inside then a thin layer of poly wadding. Oh, and if its vented, keep the wadding away from the inner end vent opening by at least 4 if you can.

(the tapered pipe is a different fish completely, which is why the wadding is only at he top in the diagram above)

Have fun !!

The speaker are going to be vented. The pipe will come out in the back, quite far down. The pipe is 48 mm wide (almost 2 in) and 100 mm long (4 in).

As I said earlier, I´m using Seas elements:

P14 RCY, woofer

size (inch): 5

element type: Polypropylen

Impedans (ohm): 8

Frekvency (Hz): 45-4000

Power: 250W

Sensitivity: 90 dB/SPL

Resonance frek (Hz): 40

Vas: 18.9

Qts: 0.19

Seas P14 RCY spec. from Seas homepage

and

H 225 19TNF, tweeter:

size (inch) 3/4

element type: polyamid

Impedans (ohm) 8

Frekvency (Hz) 4000 - 20 000

Power (W/Hz) 200/5000

sensitivity (dB/SPL) 90

Resonanse frekvency (Hz) 1700

(haven't found any datasheet on this one but since it is ony 3/4 it is probably not very beefy).

After ordering the elements I have realized that they might be a little to small for the volume so it will probably not be very strong in the lows. But since the cone is circular I cannot put too large elements on it.

As I said earlier, I´m using Seas elements:

P14 RCY, woofer

size (inch): 5

element type: Polypropylen

Impedans (ohm): 8

Frekvency (Hz): 45-4000

Power: 250W

Sensitivity: 90 dB/SPL

Resonance frek (Hz): 40

Vas: 18.9

Qts: 0.19

Seas P14 RCY spec. from Seas homepage

and

H 225 19TNF, tweeter:

size (inch) 3/4

element type: polyamid

Impedans (ohm) 8

Frekvency (Hz) 4000 - 20 000

Power (W/Hz) 200/5000

sensitivity (dB/SPL) 90

Resonanse frekvency (Hz) 1700

(haven't found any datasheet on this one but since it is ony 3/4 it is probably not very beefy).

After ordering the elements I have realized that they might be a little to small for the volume so it will probably not be very strong in the lows. But since the cone is circular I cannot put too large elements on it.

volume...

..and the volume will be about 9 liters before any of the elements and circuitries are put in it...

..and the volume will be about 9 liters before any of the elements and circuitries are put in it...

...volume

...And the speakers volume will be about 9 liters before I have put any of the elements and circuiting in it.

...And the speakers volume will be about 9 liters before I have put any of the elements and circuiting in it.

more vent length....

My calculations in WINISD and BB6 seem to indicate that what you have at the moment will give you a bass peak in the 60-75 region, not good !! Have you used WIN ISD at all? Its a free download from http://www.linearteam.dk/winisd.html and has your driver in its database. Its pretty easy to use and generally gives pretty good results for bass alignment.

It seems to indicate lengthening the vent to about 180mm. If this is too long, try reducing the radius.

My calculations in WINISD and BB6 seem to indicate that what you have at the moment will give you a bass peak in the 60-75 region, not good !! Have you used WIN ISD at all? Its a free download from http://www.linearteam.dk/winisd.html and has your driver in its database. Its pretty easy to use and generally gives pretty good results for bass alignment.

It seems to indicate lengthening the vent to about 180mm. If this is too long, try reducing the radius.

...bass peak

I don't think I can get the speakers much lower than 65 Hz which according to my calculations is what I will get. I am likely to get a muddy sound...

As for the project it's coming along nicely. I'm going to make holes for the elements tomorrow...

The element will end up sitting quite close together, a bit less than 2 in (4,5 cm) apart....

I don't think I can get the speakers much lower than 65 Hz which according to my calculations is what I will get. I am likely to get a muddy sound...

As for the project it's coming along nicely. I'm going to make holes for the elements tomorrow...

The element will end up sitting quite close together, a bit less than 2 in (4,5 cm) apart....

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Conical speakers