I got my 600VA 24V AnTek transformer today. I was surprised to notice that the input wires are 18awg while the output wires are 12awg. I would have expected them to be equal, or even for the output to be smaller. Why the large size jump?

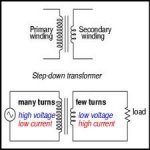

Input is High Voltage and Low Current and the Transformer Transforms to Lower Voltage and thus Higher Current capability so needs an increased current carrying wire capacity .

That's my simplistic answer...I'm sure there will be others more knowledgeable than I along to explain it more fully...😀

Transformers | Explaining The Basics of Transformers

That's my simplistic answer...I'm sure there will be others more knowledgeable than I along to explain it more fully...😀

Transformers | Explaining The Basics of Transformers

Attachments

Last edited:

What drone7 said 🙂I got my 600VA 24V AnTek transformer today. I was surprised to notice that the input wires are 18awg while the output wires are 12awg. I would have expected them to be equal, or even for the output to be smaller. Why the large size jump?

To put some numbers into it:

Voltage ratio is 120VAC (mains) to 24VAC= 120/24= 5:1

So for same VA or power, Current ratio is also 5:1

So needed copper section/area is 5:1

But area is proportional to diameter squared, so diameter ratio is sqrt 5 = 2.236:1

IF secondary is 12AWG it´s 2.053 mm diameter

So primary should be 2.053/2.236=0.918 mm diameter

They used 18AWG which is 1.024 mm diameter so slightly thicker than calculated.

Why?

Math is fine, and the basis of Tech decisions (at least it should 😉 ) but often practical or cost decisions must be considered.

18AWG is a very common and much used wire size, would not be surprised at all that it actually costs less than 0.918mm diameter wire which would be 19AWG , or they simply might have a lot of 18AWG in stock.

Can´t complain,they are giving you *more/better* for the same price 😀

I got my 600VA 24V AnTek transformer today. I was surprised to notice that the input wires are 18awg while the output wires are 12awg. I would have expected them to be equal, or even for the output to be smaller. Why the large size jump?

Input: 600VA at 120V is 5 Amps

Output: 600VA at 24V is 25 Amps

Safe wire size is related to current.

So why would a 5A wire be same size as a 25A wire?

In fact #18 in a tight bunch would burn-up with prolonged 25 Amps.

Current is one factor. Voltage is important too. The insulation is the important thing. Is the 120V insulation thicker than the 24V insulation? Why (not)?

18AWG is a very common and much used wire size, would not be surprised at all that it actually costs less than 0.918mm diameter wire which would be 19AWG , or they simply might have a lot of 18AWG in stock.

Can´t complain,they are giving you *more/better* for the same price 😀

Flexible insulated wire usually only comes in even number AWG, and they round up. I’m sure you/they could *get* #19, but it would be some silly expensive special order, even for a manufacturer. Even and odd are equally as available for the *magnet wire*, as you need to get the diameter as close as possible to the desired size to get the windings to fit. And they make just as much of one AWG as they do any other.

What drone7 said 🙂

......

But area is proportional to diameter squared, so diameter ratio is sqrt 5 = 2.236:1

.....

😀

Ahem, area of the circle is r squared x 3,14 where r is radius.

Then you must choose how many Amps for square mm you want use.

Am i wrong?

Ahem, area of the circle is r squared x 3,14 where r is radius. ... Am i wrong?

r=d/2

pi * r^2 is same as (d^2) * (pi/4) or pi * (d/2)^2

14' diameter

7' radius

7'^2 is 49, times pi makes 153.938..

14'^2 is 196, times pi is 615.752, divide by 4 is 153.938...

And yes area is "proportional to" linear dimension squared.

Sometimes it is easier to work in diameter than radius. Wire and many other things it is easier to measure over the outside than some phantom point in the center.

Not technically wrong, at all, but maybe needing a little bit more of practical/"street" experience 🙂Ahem, area of the circle is r squared x 3,14 where r is radius.

Then you must choose how many Amps for square mm you want use.

Am i wrong?

I am comparing wires used, literally what the OP asked or is worried about not making a final design by any means, so I am talking:

which of course is true.area is proportional to diameter squared

At the same time, when you go to a shop to buy wire, it is sold by AWG number (which is also a diameter scale) in USA or by diameter in mm, both in Europe and Argentina (in general we follow European rules), a shop assistant will look at you sideways or maybe even not understand if you mention "radius". 😱

As a side note, I talked "diameters" because the Math and comparison is straightforward and quick to understand as an example; now if you buy stranded wire it is sold by "section" meaning "area", first because it does not have *one* diameter but many strands and second because it´s more practical for the Electrician who is doing a Home or Shop installation.

Again, your Math is fine.

- Home

- Amplifiers

- Power Supplies

- Confused about transformer wire gauge