Besides the tall can e-caps that are not reliable at this age, you have a selenium rectifier. The big square thing in the amp chassis (with the transformer). I replaced the one in my 1961 power amp twice, the second one lasted about 8 years at ~2000 hours per year. They leak backwards, which 1n4003 almost never do. Which I recommend as a replacment, on solder terminal strips (cinch) from tubesandmore.com, triodeelectronics.com or mcmelectronics.com. I use radial lead caps mounted on terminal stripsinstead of those cans, they are a lot cheaper and they come with an hours rating. I try not to buy any e-caps rated less than 3000 hours service life. You'll need some 600 v rated wire, also available from the first two vendors (not mcm). With all those hookup harnesses, it might be easier to replace in place rather than take the amp out and pack it up.

A power strip, a grounded wall outlet, a power cord replacement plug, some wire, the resistor, capacitor and meter from the hammond service manual, are what is required for the leakage test. use clip leads for the probes and don't touch anything with the power on. A DVM should work on this test, instead of the analog one.

A power strip, a grounded wall outlet, a power cord replacement plug, some wire, the resistor, capacitor and meter from the hammond service manual, are what is required for the leakage test. use clip leads for the probes and don't touch anything with the power on. A DVM should work on this test, instead of the analog one.

Thanks again for the tips everyone.

I decided to do all the cleaning, and bond with this thing before I plunge into any testing or fixing. It'll be slow going for a while. Today I did the vacuum/brush/qtip job on the oscillators/amp and it looks 1000% better.

Indianajo, thanks for so much for your pointers. Selenium rectifier...you mean the disk above the fuse mount , right?

And regarding replacing the caps in the cans...you just use single electrolytics of the same rating, as each in the can, right? As well as the paper caps...2 of those orange paper caps exterior rotates....that can't be good.... you just use single electrolytics of the same rating? Anything special there?

It will be awhile before I get to that, but...I'm making plans....

Thanks again, more later,

Walt

I decided to do all the cleaning, and bond with this thing before I plunge into any testing or fixing. It'll be slow going for a while. Today I did the vacuum/brush/qtip job on the oscillators/amp and it looks 1000% better.

Indianajo, thanks for so much for your pointers. Selenium rectifier...you mean the disk above the fuse mount , right?

And regarding replacing the caps in the cans...you just use single electrolytics of the same rating, as each in the can, right? As well as the paper caps...2 of those orange paper caps exterior rotates....that can't be good.... you just use single electrolytics of the same rating? Anything special there?

It will be awhile before I get to that, but...I'm making plans....

Thanks again, more later,

Walt

Attachments

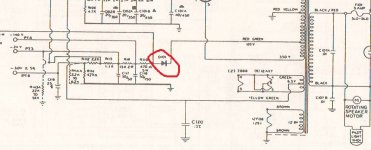

Cleaning up nicely. I see the big square thing was a metal shim for the fuse holder, not the selenium rectifier I thought I saw in the picture much dirt ago.

The "IR 2E4" grey disk is probably selenium rectifier, but even if a germanium one, a silicon rectifier like 1n4003 would be better. The plus on the old ones is the side away from the line on the new ones.

The paper wrapper on old tubular electrolytic caps did rotate, the sleeve rotation is not the problem but 50 year old rubber seals is.

However many sections are in a tall can capacitor, that is how many individual radial lead caps will be required to replace it. this is where the extra wire comes in, you'll need more negatives anyway. Most tall cans the sections are plus, but there were a few rare ones that had a negative section, watch out for that.

If an electrolytic is used of 10 uf or under, those can be replaced by film dielectric caps these days. Film is dry and should be a permanent replacement.

Note the values have changed, with new values typically +-20% and the old values typically +80% -20% unless marked with a tighter tolerance. So I usually replace 500 uf with 560 uf these days, for example. A little more voltage than originally specified is okay, but not more than 100%. Except, any 3 v rated caps, you can't buy those anymore, you have to use 25 v caps.

The "IR 2E4" grey disk is probably selenium rectifier, but even if a germanium one, a silicon rectifier like 1n4003 would be better. The plus on the old ones is the side away from the line on the new ones.

The paper wrapper on old tubular electrolytic caps did rotate, the sleeve rotation is not the problem but 50 year old rubber seals is.

However many sections are in a tall can capacitor, that is how many individual radial lead caps will be required to replace it. this is where the extra wire comes in, you'll need more negatives anyway. Most tall cans the sections are plus, but there were a few rare ones that had a negative section, watch out for that.

If an electrolytic is used of 10 uf or under, those can be replaced by film dielectric caps these days. Film is dry and should be a permanent replacement.

Note the values have changed, with new values typically +-20% and the old values typically +80% -20% unless marked with a tighter tolerance. So I usually replace 500 uf with 560 uf these days, for example. A little more voltage than originally specified is okay, but not more than 100%. Except, any 3 v rated caps, you can't buy those anymore, you have to use 25 v caps.

Hahaha turk! Good one!... I appreciate your concern! Nah I'm here. Been a month since the organ has seen power. Right now I just have a few hours on the weekend to work on it. And I don't want to load up the thread with "thanks!" replies to each reply. But I do appreciate all the suggestions and I will be back for some sanity checks before I start testing, snipping and soldering. In a week or two I may put up more photos of it totally hosed down...at least on the inside....with the power cord removed.....

Walt

Walt

- Status

- Not open for further replies.