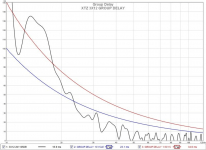

Looking at the different box-options: how important is the "group-delay" shown in HR?

I'm assuming we can tolerate longer delay for lower frequencies? What kind of delay will be ok at 50Hz? at 100Hz?

EDIT: higher order systems have longer delay? So 6th order will have longer delay than a 4th order? - is this audible for "small PA" applications?

Kind regards TroelsM

I'm assuming we can tolerate longer delay for lower frequencies? What kind of delay will be ok at 50Hz? at 100Hz?

EDIT: higher order systems have longer delay? So 6th order will have longer delay than a 4th order? - is this audible for "small PA" applications?

Kind regards TroelsM

Last edited:

https://data-bass.com/#/articles/5cc0bc36a75a260004255c88?_k=baitrtLooking at the different box-options: how important is the "group-delay" shown in HR?

I'm assuming we can tolerate longer delay for lower frequencies? What kind of delay will be ok at 50Hz? at 100Hz?

EDIT: higher order systems have longer delay? So 6th order will have longer delay than a 4th order? - is this audible for "small PA" applications?

Kind regards TroelsM

A Josh Ricci quote from his article above:

"Generally it is held that as long as the delay is below 1.5 cycles in the bass range it is inaudible and most studies indicate that less than 1 cycle of delay in the bass range is inaudible. Additionally the deeper in frequency, the longer the wavelength and the less sensitive our ears and body become to delayed energy. Generally GD below 25-30Hz is not a concern unless it is very bad. The lowest frequencies are extremely long and slow. For example 40ms of delay at 25Hz is probably not audible, but 40ms of delay at 100Hz could be of concern. Typically sealed, IB and other lower order systems offer the least amount of delay...Bass reflex systems typically have increased delay near the resonator tuning. Higher order, more complex systems like horns and band-pass enclosures can have more group delay and more complex delay plots. Additionally equalization and other signal processing, such as high and low pass filters, or parametric signal shaping can increase the group delay. Usually this measurement type indicates nothing of concern unless the group delay is exceeding 1.5 cycles above 30Hz and / or there is a very abrupt spike in group delay over a narrow frequency band ."

In a "small PA" application, the program material and room will probably dominate most perception of what could be considered audible, unless the crossover region has considerable group delay.

Attachments

I havnt heard of the "pioneer default prosound alignment", but it makes sense in this case: lots of output, limited low-end and low excursion.Hmm, all things considered in your postings, (published) driver specs + added 0.5 ohms for wiring = (~0.33 Qts'), personally would go with the pioneer's default prosound alignment, which provides enough more mid-bass 'punch' that for many (most/all?) live event goers prefer over a little lower bass 'fullness': Vas/1.44, Fb = 1.56x Fs, which HR calcs ~ -3 dB/your ~55 Hz bass mean, allowing full rated power @ 4.6 mm (18 m/s) and of course ideally need to be measured specs and averaged if multiples.

[Qts']: [Qts] + any added series resistance [Rs]: http://www.mh-audio.nl/Calculators/newqts.html

It´s "boring" but efficient 🙂. I will look at other options, but this one looks good for the application.

Maybe my implementation would be a bit smaller and sacrifice some efficience.

For reference I plotted the response:

I mentioned cooling in the first post:

If the sub is ever build, it will be active and it must be able to endure full volume (music) for hours. The amp will be a classD-solution and although its efficient there is still losses. As the classD and SMPS are much smaller than the comparable size AB-amp, heat is concentrated in a smaller area/volume.

I would like to experiment with having both the driver and amp-SMPS exposed to "outside" air and/or be subjected to the airflow/turbulence from the speaker-port(s). I realize that there is very little net-flow and that we want to avoid turbulence in the ports, but I believe that even minimal air-movement around the hot electronics will have an effect.

Of cause its possible to place the electronics inside the BR and have the internal port-ending "blow" on the electronics. - but the electronics is still inside the box and the speaker-magnet is not cooled. With a port-size around 250cm2 I can place the electronics inside the port and only restrict airflow a little, so definitely an option.

So, I'm looking at cabinet-options that allows: a) magnet to placed on the outside and b) electronics to be placed partially outside and in some "flow" in/around the port(s).

A tapped horn fits both a) and b), but a TH will be larger than my goal.

I have looked at 6th order (series) cabinets as an option. Inspired by some comments from member PatrickBateman that said something like: "A BP6S can be tuned to whatever you like: low cut-off, high efficiency or anything in between" ( sorry, cant find the relevant thread right now).

For a BP6S the front-chamber can be relatively small and the "port" can basically be a large opening in the box. That should enable an option for cooling.

I think it will be a little less efficient than the "pioneer-Pro-BR", but so far it really looks like it can be made to go low and be less efficient or vice versa.

Hope it makes sense. Examples will follow when I have the time.

Kind regards TroelsM

If the sub is ever build, it will be active and it must be able to endure full volume (music) for hours. The amp will be a classD-solution and although its efficient there is still losses. As the classD and SMPS are much smaller than the comparable size AB-amp, heat is concentrated in a smaller area/volume.

I would like to experiment with having both the driver and amp-SMPS exposed to "outside" air and/or be subjected to the airflow/turbulence from the speaker-port(s). I realize that there is very little net-flow and that we want to avoid turbulence in the ports, but I believe that even minimal air-movement around the hot electronics will have an effect.

Of cause its possible to place the electronics inside the BR and have the internal port-ending "blow" on the electronics. - but the electronics is still inside the box and the speaker-magnet is not cooled. With a port-size around 250cm2 I can place the electronics inside the port and only restrict airflow a little, so definitely an option.

So, I'm looking at cabinet-options that allows: a) magnet to placed on the outside and b) electronics to be placed partially outside and in some "flow" in/around the port(s).

A tapped horn fits both a) and b), but a TH will be larger than my goal.

I have looked at 6th order (series) cabinets as an option. Inspired by some comments from member PatrickBateman that said something like: "A BP6S can be tuned to whatever you like: low cut-off, high efficiency or anything in between" ( sorry, cant find the relevant thread right now).

For a BP6S the front-chamber can be relatively small and the "port" can basically be a large opening in the box. That should enable an option for cooling.

I think it will be a little less efficient than the "pioneer-Pro-BR", but so far it really looks like it can be made to go low and be less efficient or vice versa.

Hope it makes sense. Examples will follow when I have the time.

Kind regards TroelsM

Dont know if the sketch makes sense, but here is the rough idea for BP6S.

Driver is green, internal ports blue and red is electronics.

Driver is green, internal ports blue and red is electronics.

Not surprised, I made it up in another lifetime after reverse engineering W.E./Lansing/Altec cab alignments that showed an obvious 'trend' that reminded me of what I'd been told during an Altec plant tour, then very quickly afterwards was published for all here [pg. 76] [so much for me arrogantly thinking I was getting 'insider' tech info 🙁]: https://archive.org/details/HowToBuildSpeakerEnclosuresByAlexixBadmaieffDonDavis/page/n75/mode/2upI havnt heard of the "pioneer default prosound alignment", but it makes sense in this case: lots of output, limited low-end and low excursion.

It´s "boring" but efficient 🙂

It does, but my SWAG is that you've created a driver 'pressure cooker' with convection cooling only when not turned on for an extended time, i.e. much longer than a high Q dip in the power response.Dont know if the sketch makes sense, but here is the rough idea for BP6S.

Driver is green, internal ports blue and red is electronics.

IME it either needs some form of cooler or driver out in free air where there's a significant temperature differential draft.

Oops! I forgot to check 'lossy Le' to show a bit more accurate high power response. 🙁For reference I plotted the response:

Not completely sure what you mean with "pressure cooker", but let me specify that cab will be placed with big port on the side and NOT top. (possible that port in top would be better for heat-transfer, but it is also MUCH more vulnerable when people spil beer and drinks 🙂 )It does, but my SWAG is that you've created a driver 'pressure cooker' with convection cooling only when not turned on for an extended time, i.e. much longer than a high Q dip in the power response.

IME it either needs some form of cooler or driver out in free air where there's a significant temperature differential draft.

Pressure cooker in that the low pass filter chamber's compression ratio may 'pump up' during any high power LF/mid-bass sustains or its ~ 'fast' modulation equivalents, keeping the driver from getting any real cooling same as some sealed FLHs have been known to do, not to mention the bane of mids/HF compression horns. Probably need to factor in the local ambient temp also and guessing that the vent needs to be at least Av = Sd to even begin to have any worthwhile heat transfer.

Yes, definitely a universal problem! 🙁

Anyway, no experience with such compact vented, crazy high power cabs [I never even imagined such in my active audio 'career'], only know much larger, lower power horns have been known to 'spit'/'shoot' the VC out into the crowd if not screened over, though modern design/manufacturing may have rendered such issues moot, so looking forward to how all this pans out.

Yes, definitely a universal problem! 🙁

Anyway, no experience with such compact vented, crazy high power cabs [I never even imagined such in my active audio 'career'], only know much larger, lower power horns have been known to 'spit'/'shoot' the VC out into the crowd if not screened over, though modern design/manufacturing may have rendered such issues moot, so looking forward to how all this pans out.

- Home

- Loudspeakers

- Subwoofers

- Compact PA-sub ideas with 12-280/8-W