Hi all,

I recently got one of these. Have been spending the past few days bringing it back to life. It actually sounds superb. Better than my sondek. Only issue is some rumble. Just wondering if anyone has had experience tweaking out the rumble from this idle drive beast.

I think the source is the platter and the ball bearing it sits on. The rumble is getting transmitted into the needle from the platter as its not present when the arm is up. Are there any good mats that can reduce rumble?

Yes thats a vice grip holding the tonearm onto the rim of the turntable, yes thats un upside down ikea stool being used as a plinth. thats a 9" audio technica broadcast arm. My intent is to make a slate plinth and use an sme 3012 12" arm. This is just a quick and dirty rig to get it working. But to my suprise it sounds very very good.

I recently got one of these. Have been spending the past few days bringing it back to life. It actually sounds superb. Better than my sondek. Only issue is some rumble. Just wondering if anyone has had experience tweaking out the rumble from this idle drive beast.

I think the source is the platter and the ball bearing it sits on. The rumble is getting transmitted into the needle from the platter as its not present when the arm is up. Are there any good mats that can reduce rumble?

Yes thats a vice grip holding the tonearm onto the rim of the turntable, yes thats un upside down ikea stool being used as a plinth. thats a 9" audio technica broadcast arm. My intent is to make a slate plinth and use an sme 3012 12" arm. This is just a quick and dirty rig to get it working. But to my suprise it sounds very very good.

Attachments

I take you have cleaned and lubed the beatings etc.

Could it be due to the arm being mounted straight to the aluminium chassis?

I'd try something between armbase and chassis and between vice grip and chassis: wood, plastic, rubber?

regards

james

Could it be due to the arm being mounted straight to the aluminium chassis?

I'd try something between armbase and chassis and between vice grip and chassis: wood, plastic, rubber?

regards

james

Hi James, nk I havent cleaned and lubed. There was some lube still the. Do you know what to use? Motor oil, machine grease?

Reason I don't think it's the chassis mounting is that its dead quiet when arm is up, and obviously still mounted to chassis. But I will try whay you suggest as well.

thanks.

Reason I don't think it's the chassis mounting is that its dead quiet when arm is up, and obviously still mounted to chassis. But I will try whay you suggest as well.

thanks.

Ah thanks so much for the link to the manual for the 16A. That is a huge help. it seems my issues are more related to the Idler wheel. It's either the alignment of it (ie how parallel it is to the Chassis) or perhaps a flat spot on the tyre of the Idler wheel itself. So I'm going through a process of elimination starting with sorting out the alignment.

With the platter off it's possible to put my ear against the chassis. The noise I was hearing (ie a repeating faint beat) is apparent without the platter attached. So I now know it's not the platter bearing.

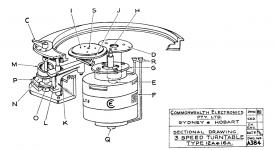

In order to adjust the idler wheel alignment, a small aluminium linkage (the manual refers to as the "Dural" Linkage, "J" in the attached image) must be bent. This issue of misalignment is refered to as "Scrubbing" in the manual. So I've just spent the past 45mins removing the Dural vice clamping to my balcony rail and carefully bending it, reinstalling it, then checling the alignment against the chassis with the edge of a 600mm steel ruler. A painstaking process that I haven't yet got right. The Dural is a rugged little metal part that's tricky bend accurately. I typically overshoot or undershoot the bend.

Once I've adressed the alignment issue as best I can, If the issue is still persisting I will need to progress to grinding the Tyre of the IDler Wheel. I fortunately have a precision lathe, and If anyone has done this job before I'd appreciate any tips. e.g. do you use sandpaper to grind the wheel?

Tvi thanks so much for the link to the manual, this is a very big help. I will also track down the appropriate motor oil and grease. Not sure about you question of the detergent in the oil. Well thanks so much.

Well it's a beautifully simple engineered thing this commonwealth. Sort of agricultural and rugged but logical. There are a few frustrating non maintence friendly aspects to it but overall I'm impressed with whoever designed the thing back in the day. A fair bit of thought has gone into this thing.

With the platter off it's possible to put my ear against the chassis. The noise I was hearing (ie a repeating faint beat) is apparent without the platter attached. So I now know it's not the platter bearing.

In order to adjust the idler wheel alignment, a small aluminium linkage (the manual refers to as the "Dural" Linkage, "J" in the attached image) must be bent. This issue of misalignment is refered to as "Scrubbing" in the manual. So I've just spent the past 45mins removing the Dural vice clamping to my balcony rail and carefully bending it, reinstalling it, then checling the alignment against the chassis with the edge of a 600mm steel ruler. A painstaking process that I haven't yet got right. The Dural is a rugged little metal part that's tricky bend accurately. I typically overshoot or undershoot the bend.

Once I've adressed the alignment issue as best I can, If the issue is still persisting I will need to progress to grinding the Tyre of the IDler Wheel. I fortunately have a precision lathe, and If anyone has done this job before I'd appreciate any tips. e.g. do you use sandpaper to grind the wheel?

Tvi thanks so much for the link to the manual, this is a very big help. I will also track down the appropriate motor oil and grease. Not sure about you question of the detergent in the oil. Well thanks so much.

Well it's a beautifully simple engineered thing this commonwealth. Sort of agricultural and rugged but logical. There are a few frustrating non maintence friendly aspects to it but overall I'm impressed with whoever designed the thing back in the day. A fair bit of thought has gone into this thing.

Attachments

Last edited:

These are very, very nice tables, great score. A high mass lossy plinth should reduce rumble significantly. (Plywood layered for example, or paperstone) They're rare here, but well regarded so I have seen a few.

As I recall the motor is mounted on bushings which may need replacement.

I would not do a whole lot of adjustment, etc. until it is properly plinthed - some of what you are proposing to do may be unnecessary.

As I recall the motor is mounted on bushings which may need replacement.

I would not do a whole lot of adjustment, etc. until it is properly plinthed - some of what you are proposing to do may be unnecessary.

I think you're absolutely right Kevinkr. I removed the arm from clamping it to the chassis rim and simply put it on a stand separate from the chassis. Big improvement already. Sounds great.

Yeah these big boy turntables are one of the few things we in Australia have good access to compared to you guys in the northern hemisphere. Pretty much everything else you guys have more of.

Yeah these big boy turntables are one of the few things we in Australia have good access to compared to you guys in the northern hemisphere. Pretty much everything else you guys have more of.

Attachments

Good news, I was wondering about clamping the arm to the motor board, particularly when not plinthed. Some arms are much more susceptible than others to this coupling mode.

Not exactly a desert of 16 inch transcription tables here either; we've got Gates, Russco, and Fairchild tables to play with as well as RCA types. They're obviously much rarer than 12 inch tables, but I have seen all of the above in 16 inch versions.

I had one shot at a Fairchild 750, but it was a bit pricey and rather too large to fit comfortably into my listening space. (I've got two TD-124s running and a 401in the wings)

A friend has a Commonwealth 16 (not sure of the specific model) which he has started to work on I think. He'll run it on 50Hz/240V power.

Not exactly a desert of 16 inch transcription tables here either; we've got Gates, Russco, and Fairchild tables to play with as well as RCA types. They're obviously much rarer than 12 inch tables, but I have seen all of the above in 16 inch versions.

I had one shot at a Fairchild 750, but it was a bit pricey and rather too large to fit comfortably into my listening space. (I've got two TD-124s running and a 401in the wings)

A friend has a Commonwealth 16 (not sure of the specific model) which he has started to work on I think. He'll run it on 50Hz/240V power.

Cool sounds like you've got some great turntables running there. I also have 2 of these "Austral Argo" rim drive 16" tables. I've never seen another like them. These are also Aussie, but I think are essentially copies of a Presto design. Lots of fun these things.

Attachments

I'm not very familiar with the Presto, but it looks a lot like what I remember. Strangely I may have seen an actual Argo. LOL

I don't have anything that exotic of course, and only occasionally see these things.

I had a Russco Studio B (12 inch idler drive) at one time that I ended up gifting to a friend, I have no idea what he did with it. (Something I hope)

A number of my friends are playing with Rondines of various vintages. I remember at one time many considered them a bit of a joke (of course that is true of the drivers in my system as well), today people are scrambling for cleaner examples of them, and new parts are available to restore them. Big change over a couple of decades.

Interesting as a kid I could not wait to get away from idler drive tables, considered them chintzy. Belt and finally direct drive, and then belt and finally back to idler. The best tables I have ever owned are the current ones, and they're, umm all idlers.. LOL

I don't have anything that exotic of course, and only occasionally see these things.

I had a Russco Studio B (12 inch idler drive) at one time that I ended up gifting to a friend, I have no idea what he did with it. (Something I hope)

A number of my friends are playing with Rondines of various vintages. I remember at one time many considered them a bit of a joke (of course that is true of the drivers in my system as well), today people are scrambling for cleaner examples of them, and new parts are available to restore them. Big change over a couple of decades.

Interesting as a kid I could not wait to get away from idler drive tables, considered them chintzy. Belt and finally direct drive, and then belt and finally back to idler. The best tables I have ever owned are the current ones, and they're, umm all idlers.. LOL

goldjazz, nice table you have there. You say you have a precision lathe? Well you will need to mount the idler wheel and grind the face of it. I assume there is some sort of a bored hole or ball bearing in the center.

You need to have that center hole running dead true or max total indicated runout at 0.0005" or less. If the idler has a ball bearing, knock it out and chuck up a piece of aluminum and turn a diameter that will allow the idler to fit on with a snug fit. Tap a center hole and secure the idler with a bolt and washer. That will ensure that the idler is running dead true.

Sandpaper will only follow the contour of what is already there. You will need a toolpost grinder mounted into your tool post to grind the O.D. concentric to the bore. If need be, rig up a die grinder to fit into the tool post. Use the coarsest grinding stone you have. Take very light passes and allow the rubber to cool or it will expand with the heat and push into the wheel.

Just take your time and it should clean up like new. Take some pictures as you go along and share them with us. Yea, I used to be a tool maker in another life......

BillWojo

You need to have that center hole running dead true or max total indicated runout at 0.0005" or less. If the idler has a ball bearing, knock it out and chuck up a piece of aluminum and turn a diameter that will allow the idler to fit on with a snug fit. Tap a center hole and secure the idler with a bolt and washer. That will ensure that the idler is running dead true.

Sandpaper will only follow the contour of what is already there. You will need a toolpost grinder mounted into your tool post to grind the O.D. concentric to the bore. If need be, rig up a die grinder to fit into the tool post. Use the coarsest grinding stone you have. Take very light passes and allow the rubber to cool or it will expand with the heat and push into the wheel.

Just take your time and it should clean up like new. Take some pictures as you go along and share them with us. Yea, I used to be a tool maker in another life......

BillWojo

Whoa BillWojo that is some awesome knowledge you have there. Thanks so much for sharing. Ok well i seemed to get some good improvements from isolating the arm. So I'm gonna make a slate plinth for it first and mount everything in that. If i think there still make be an issue due to a flat spot I will follow your advice and upload pics. If I don't end up needing to do it on this TT able no doubt your advice will come in handy on a future one. Thanks very much

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Commonwealth electric 16"