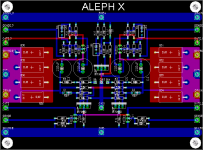

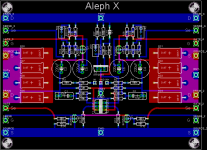

I'm certainly not an expert in PCB's but it looks like you reserved no space for the diffpair heatsink. They can live without but DC will be more stable if you connect them thermally.

/Hugo 🙂

/Hugo 🙂

pcb-layout

Hello Kari,

Nice symmetrical design.

Maybe the powerlines are a little thin. Make them dubblesided with some via's to connect them.

Did you have any special reason to use 90 degrees curves?

Regards,

Johan.

Hello Kari,

Nice symmetrical design.

Maybe the powerlines are a little thin. Make them dubblesided with some via's to connect them.

Did you have any special reason to use 90 degrees curves?

Regards,

Johan.

Did you have any special reason to use 90 degrees curves?

Shorter trace length? 😀

You could add some heat-relief traces to make soldering easy. My Aleph-X board was quite difficult to solder, as I had none.

--

Brian

--

Brian

Hi,

thanks for the input. No i don't have any special reason for 90 degree angels on the tracks. Does it matter?

BrianGT: As i am using Eagle for this i assume u mean "thermals" on the pads?

I also got the quote from my pcb fab. 4 pcs with redsolder mask is 100USD (I will order this). However if anyone is interested i can get 10pcs for 120USD and 20 pcs for 190USD.

I'll post a new picture of the pcb as soon as i'm done with the modifications.

Thx again,

Kari

thanks for the input. No i don't have any special reason for 90 degree angels on the tracks. Does it matter?

BrianGT: As i am using Eagle for this i assume u mean "thermals" on the pads?

I also got the quote from my pcb fab. 4 pcs with redsolder mask is 100USD (I will order this). However if anyone is interested i can get 10pcs for 120USD and 20 pcs for 190USD.

I'll post a new picture of the pcb as soon as i'm done with the modifications.

Thx again,

Kari

Kari said:BrianGT: As i am using Eagle for this i assume u mean "thermals" on the pads?

Yes, thermals = heat relief traces

--

Brian

curves

Dont use 90 degree angles. It is not good, the width of the trace changes and so does the impedance. Round curve is the best one, but 45 degree angle will do nicely.

Regards

Anvil

Dont use 90 degree angles. It is not good, the width of the trace changes and so does the impedance. Round curve is the best one, but 45 degree angle will do nicely.

Regards

Anvil

pcb

Hi,

you should add some space between the diff-pair to spend a little heatsink to the fets and perhaps some more space to the componrents around (depends on the dimensions of the heatsink).

Would be interested in some boards, too.

Bye

Hi,

you should add some space between the diff-pair to spend a little heatsink to the fets and perhaps some more space to the componrents around (depends on the dimensions of the heatsink).

Would be interested in some boards, too.

Bye

Hi Kari,

Nice design.

This may be a stupid question, but can't you get away with using just a single sided PCB ?

That would probably cut the cost a bit ?

I think that would be possible with out to much of a hazzle.

But I may be wrong.

Best Regards,

Gunnar I.T.

Nice design.

This may be a stupid question, but can't you get away with using just a single sided PCB ?

That would probably cut the cost a bit ?

I think that would be possible with out to much of a hazzle.

But I may be wrong.

Best Regards,

Gunnar I.T.

90 degree angles

Hi all,

It's a fact, when you use a simple home-made etching machine(english ?) and there are 90 degree angles on your board,there will be a change of underetching in the curve. So the width changes. With a professional machine it's no problem.

Otherwise when you look at the Passdiy designs, you see no 45 degree angles. Maybe their design software didn't support that at that days or it's the hand of the designer(Mr.Colburn).

Once i asked a full time pcb-designer(hf-boards) about this item and he said it doesn't matter.

So confusion all around.

Maybe one of the pcb-guru's on the forum can make this clear ???

Best regards,

Johan.

Hi all,

Dont use 90 degree angles. It is not good, the width of the trace changes and so does the impedance.

It's a fact, when you use a simple home-made etching machine(english ?) and there are 90 degree angles on your board,there will be a change of underetching in the curve. So the width changes. With a professional machine it's no problem.

Otherwise when you look at the Passdiy designs, you see no 45 degree angles. Maybe their design software didn't support that at that days or it's the hand of the designer(Mr.Colburn).

Once i asked a full time pcb-designer(hf-boards) about this item and he said it doesn't matter.

So confusion all around.

Maybe one of the pcb-guru's on the forum can make this clear ???

Best regards,

Johan.

At high frequencies, signals "fly" off the corners of traces and corrupt other signal traces. Because of this, it is a general no-no in design to use them, but in the audio frequency range it does not make much of a difference other than keeping traces as short as possible.

-Matt

-Matt

Impedance variations from 90 deg turns really have no relevance in audio design, -- that is if one looks at a max bandwidth of 50 - 100 kHz...maybe Pass lab designs can be proof of this..... However,- the "Golden Ear" community make substantial claims of hearing sonic differences. I seriously doubt there will be any concensus in this matter in a VERY long time.

On the other side, I think there is a general concensus that 45s or round turns are more pleasing to the eye. Being at least partly a professional designer myself ( I just don't have enough spare time for any serious audio..), -- I try to avoid sharp angles , partly for visual reasons, partly for "just maybe I believe that" reasons..😉

EDIT: Zaqis comment on short traces is of course very relevant!

On the other side, I think there is a general concensus that 45s or round turns are more pleasing to the eye. Being at least partly a professional designer myself ( I just don't have enough spare time for any serious audio..), -- I try to avoid sharp angles , partly for visual reasons, partly for "just maybe I believe that" reasons..😉

EDIT: Zaqis comment on short traces is of course very relevant!

Curves and thermals

Yes, some people have "bionic" ears, just like the six million dollar man.

Thank you for the explanation i had the same thoughts.

By the way, Eagle has for short lines also a point to point option but for cosmetic reasons... 45 degrees looks better.

Another question ;

I was playing with the "thermals" option in Eagle and i expected four thin lines from the pad to the polygoon. Unfortunately the pad is complete isolated (or complete connected).

Is that right ?

or is there some secret setting for such a option?

Regards,

Johan.

- the "Golden Ear" community make substantial claims of hearing sonic differences.

Yes, some people have "bionic" ears, just like the six million dollar man.

Thank you for the explanation i had the same thoughts.

By the way, Eagle has for short lines also a point to point option but for cosmetic reasons... 45 degrees looks better.

Another question ;

I was playing with the "thermals" option in Eagle and i expected four thin lines from the pad to the polygoon. Unfortunately the pad is complete isolated (or complete connected).

Is that right ?

or is there some secret setting for such a option?

Regards,

Johan.

I have Eagle freeware installed, just to open stuff posted on this board....I use OrCAD at work and can move my licenses to do stuff for myself during weekends......

Are you sure it is not a visual on-screen effect??

Also, there must be a setting somewhere to regulate the width of the thermal spokes.....any Eagle experts here ???

Are you sure it is not a visual on-screen effect??

Also, there must be a setting somewhere to regulate the width of the thermal spokes.....any Eagle experts here ???

dobbeln: No i will not include a heatsink, takes too much space when it is not really needed.

Gunnar: My pcb fab charges me the same amount of money regardless if the pcb is single or double sided. And designing doublesided gives you much more freedom.

I'll check on those 90 degree "turns", however i feel that it doesn't matter if they are 90 or 45 degrees or not. I do agree that it will "look" better if the bends are 45 degree angle or bent.

Stay tuned as i progress on my pcb.

And a big thanks to everyone replaying 🙂

/Kari

Gunnar: My pcb fab charges me the same amount of money regardless if the pcb is single or double sided. And designing doublesided gives you much more freedom.

I'll check on those 90 degree "turns", however i feel that it doesn't matter if they are 90 or 45 degrees or not. I do agree that it will "look" better if the bends are 45 degree angle or bent.

Stay tuned as i progress on my pcb.

And a big thanks to everyone replaying 🙂

/Kari

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- Comments on my Aleph-X layout?