Hello all, I have the QSC GX3 amplifier. This amp has run 24/7 for 14 years. I opened it up recently and found this:

Nothing unusual in forced cooled PA amps.

But I admit it's scary at first sight.

A compressor is your friend. 🙂

Hugo

But I admit it's scary at first sight.

A compressor is your friend. 🙂

Hugo

If dust is critical you must put your equipment into a climate controlled box. For Servers they do exist but it's expensive.

In dusty areas like deserts cumulation of dust is a problem: solar panels must be cleaned by hand because it never rains.

Technique works non stop with fans at maximum - in summertime it can get 40 degrees Celsius plus self warming of the equipment.

So closing the windows against new incoming dust in the air and putting the clima cooling on prevents overheating and dust accumulation

In dusty areas like deserts cumulation of dust is a problem: solar panels must be cleaned by hand because it never rains.

Technique works non stop with fans at maximum - in summertime it can get 40 degrees Celsius plus self warming of the equipment.

So closing the windows against new incoming dust in the air and putting the clima cooling on prevents overheating and dust accumulation

After cleaning the fan heat sink and pcb, I put a fliter over the fan inlet. Tacky fiber filter material I buy in rolls. https://www.mcmaster.com/products/hvac-air-filters/air-filter-rolls/

I punch ty-wraps through the filter material and loop them through the inlet grill. If fan is too close to the inlet, holes can be drilled around the grill for screws and elastic stop nuts. I use #6-32 x 1" for this service.

I buy 24" or 30" wide rolls and use the same material for my window A/C and furnace unit. Also get tied over the back of room fans. It cuts with scissors.

To avoid overheating the appliance the filter should be changed every 2000 hours operation or so, or when you notice a layer of dust accumlating.

I punch ty-wraps through the filter material and loop them through the inlet grill. If fan is too close to the inlet, holes can be drilled around the grill for screws and elastic stop nuts. I use #6-32 x 1" for this service.

I buy 24" or 30" wide rolls and use the same material for my window A/C and furnace unit. Also get tied over the back of room fans. It cuts with scissors.

To avoid overheating the appliance the filter should be changed every 2000 hours operation or so, or when you notice a layer of dust accumlating.

Last edited:

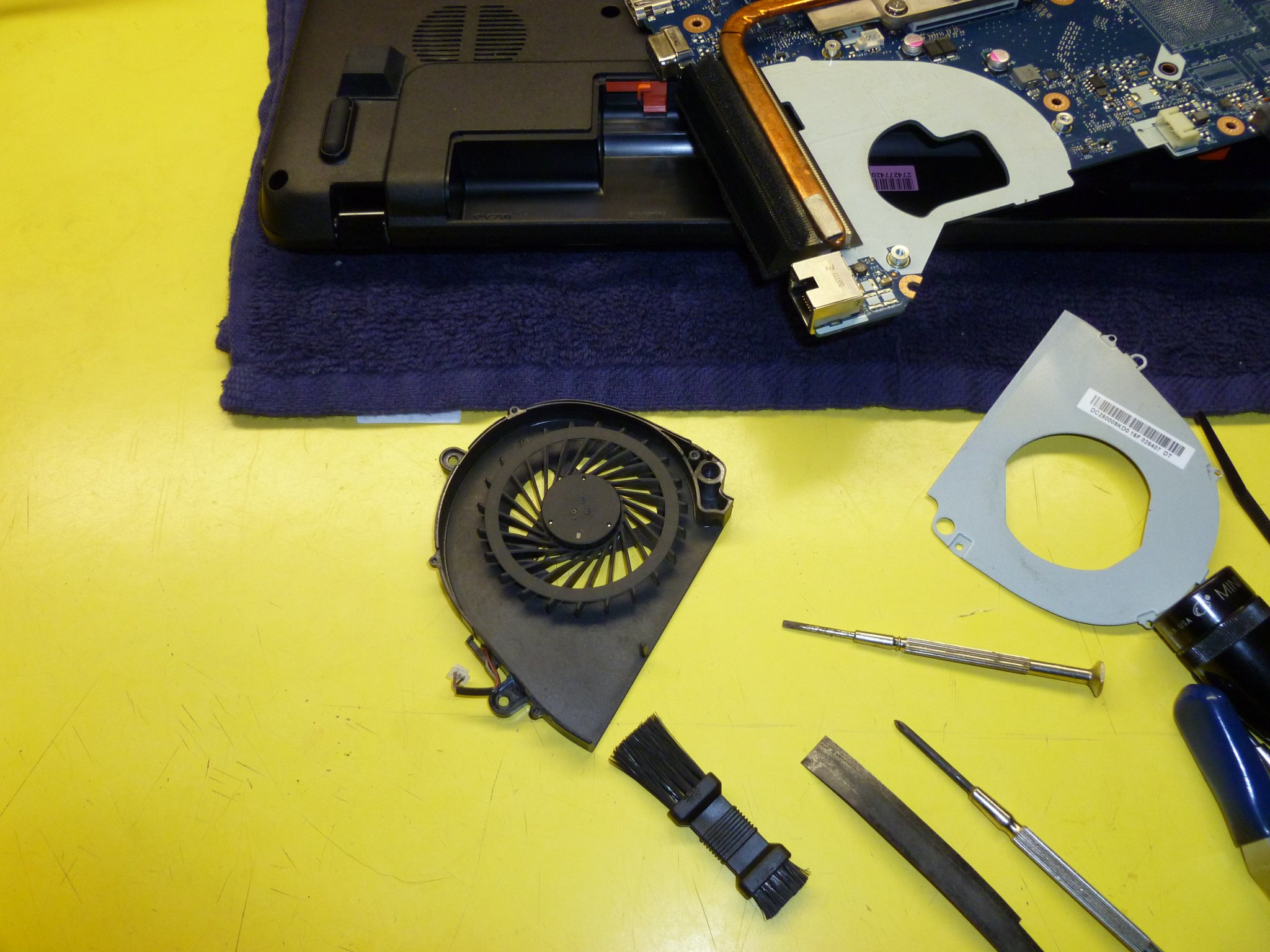

The QSC amplifier is in the room where I live. My PC fan did the same thing, it stopped with a scream/squeak. It is sad to note we live in a world of dust and mold 24/7.

I cleaned the fan with a small paint brush and vacuum cleaner. The QSC GX3 has holes/vents on all four sides, with no specific inlet or outlet path. I will clean it on a yearly basis from now on.After cleaning the fan heat sink and pcb, I put a fliter over the fan inlet.

My QSC CX302 has one air inlet, several outlets.

The tree pollen is so thick late February & early March here it forms a tan coating on the sidewalk and cars. I sneeze my head off every night from 2200 to 0400. The reason for room fans with a filter on the back. I have beautiful cedar trees in my yards, that pollute the air with pollen.

The tree pollen is so thick late February & early March here it forms a tan coating on the sidewalk and cars. I sneeze my head off every night from 2200 to 0400. The reason for room fans with a filter on the back. I have beautiful cedar trees in my yards, that pollute the air with pollen.

At least you didn't breathe the dust they collected. 😆It is sad to note we live in a world of dust and mold 24/7.

I serviced many pro amps in the past and those from clubs and bars were the worst.

These guys play till it breaks.

Anything with fans in it have that problem, PC's and their power supplies to name one.

A small compressor can be had for +/- 100 euro, a well worth investment.

Hugo

Hello Hugo - As for the QSC GX3. This amp has 2 channel stereo or subwoofer/satellite mode with a built in crossover. I use is as a center channel amplifier, using the crossover. My subwoofer below 100Hz is a cinema F-20 diy from Lilmike on the AVS forum. I use the McCauley 6174 as the motor. The center channel above 100Hz is a diy modified design of the Peavey FH-1, using all vintage Electro-Voice drivers. EVM 15B, HR60/DH1012A, ST350A.

Build like 'In the Old Days'.

Simple and robust, I bet they can rattle the house.

Love it, thanks.

Hugo

Simple and robust, I bet they can rattle the house.

Love it, thanks.

Hugo

Hello again Hugo, you did ask. The QSC 3200 amps are used in another 2 channel system. Left channel is 2 x TL606 diy style cabs using EVM 15B, SM120A/DH1506, ST350B drivers. The right channel is a diy style TL606D for the bottom, easier build than 2 separate cabs, but harder to move. Using the same drivers. One QSC 3200 drives them stereo

. The other QSC 3200 is bridged to run my other subwoofer, a diy TL 405 style cab with the EV DL18MT.

. The other QSC 3200 is bridged to run my other subwoofer, a diy TL 405 style cab with the EV DL18MT.

- Home

- Live Sound

- PA Systems

- Clean your Amplifier cooling fan