Here's my DIY turntable prototype using parts left over from a previous upgrade.

The pulley size isn't optimized yet, and I need to have one custom made.

I also want a 1" thick alumimum as the plinth for this project. I aim for 2-arm configuration.

An externally hosted image should be here but it was not working when we last tested it.

The pulley size isn't optimized yet, and I need to have one custom made.

I also want a 1" thick alumimum as the plinth for this project. I aim for 2-arm configuration.

Nice,

Im already planning a DIY TT using my SME 3010R arm.

Can you tell me more about the motor you use?

regards

Klook

Im already planning a DIY TT using my SME 3010R arm.

Can you tell me more about the motor you use?

regards

Klook

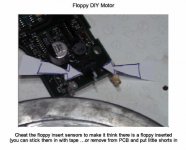

The motor is a floppy drive motor 😉 Effortless to turn the platter. Check the AudioOrigami website for details. Mine is a Sony branded one.

It seems that the floppy drive project in the audio origami website is no longer available! 🙁

Is there another place where I can find it?

regards

Klook

Is there another place where I can find it?

regards

Klook

Thank you Nanook!

Is this floppy motor capable of turning a 3 inches acrylic platter?

And how is it possible to do a good quality bearing?

\0/s

Leo

Is this floppy motor capable of turning a 3 inches acrylic platter?

And how is it possible to do a good quality bearing?

\0/s

Leo

Hi Leo,

Th floppy motor (at least this one I used) has lots of torque. It can spin the heavy TNT composite platter without any effort.

For the bearing, there's a post here on how to use Harley-Davidson parts to make a bearing.

Th floppy motor (at least this one I used) has lots of torque. It can spin the heavy TNT composite platter without any effort.

For the bearing, there's a post here on how to use Harley-Davidson parts to make a bearing.

Does anyone know what brand of floppy drive this is?

Every one I've tried has some opto switch to sense the disk. In addition I could not find the resistor to adjust the speed. One like this or similar would be just the ticket.

regards BT

Every one I've tried has some opto switch to sense the disk. In addition I could not find the resistor to adjust the speed. One like this or similar would be just the ticket.

regards BT

opto switches...

look at the link . A discussion on defeating the opto sensor is in there, as is the process for determining the resistor value/ pt to tie into.

c'mon guys. Read the link, then ask the questions

A DIY could be made from a discarded VCR head/bearing assembly.

Every one I've tried has some opto switch to sense the disk. In addition I could not find the resistor to adjust the speed. One like this or similar would be just the ticket.

look at the link . A discussion on defeating the opto sensor is in there, as is the process for determining the resistor value/ pt to tie into.

c'mon guys. Read the link, then ask the questions

A DIY could be made from a discarded VCR head/bearing assembly.

If I hadn't read the article I would not be asking the question.

There is nothing about opto sensors in this article and I cannot find and I can't find a resistor that will adjust the speed.

Which is why I'm asking for the brand/model.

Regards BT

There is nothing about opto sensors in this article and I cannot find and I can't find a resistor that will adjust the speed.

Which is why I'm asking for the brand/model.

Regards BT

BT,

My Sony floppy disk is very much different from the one at Audio Origami. Can you post a pic of yours, and I'll see if I can help you.

My Sony floppy disk is very much different from the one at Audio Origami. Can you post a pic of yours, and I'll see if I can help you.

Hi BT, i was hoping you can post a picture of your floppy drive unit.

Here's mine-

Here's mine-

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

it doesn't mentioning defeating the opto sensor directly, but tells you which pins to short on the rear cable connection.

In my case, the sensor is on the amputated part 😀 I shorted it out on the other end, and makes it think there's always a floppy in the drive.

Hi Stew,

This is to bypass the microswitches. In the floppy drive I have this only get you so far. The optoswitch seems to generate a pulse, so wiring it out would not work.

Regards BT

This is to bypass the microswitches. In the floppy drive I have this only get you so far. The optoswitch seems to generate a pulse, so wiring it out would not work.

Regards BT

If that floppy is too much of a trouble, then use a different one. There are lots to choose from.

I used the Sony Floppy Disk model MPF920 that seems to be popular.

I've tidied up the motor on my turntable, as shown:

Here it is in action. I'm very much satisified with the performance.

The floppy drive motor works best powered by PDA wall warts as they seem to be regulated and give hefty stable 5V. I'm current using one I salvaged from my broken iPaq.

I've tidied up the motor on my turntable, as shown:

An externally hosted image should be here but it was not working when we last tested it.

Here it is in action. I'm very much satisified with the performance.

An externally hosted image should be here but it was not working when we last tested it.

The floppy drive motor works best powered by PDA wall warts as they seem to be regulated and give hefty stable 5V. I'm current using one I salvaged from my broken iPaq.

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Cheating on a DIY turntable