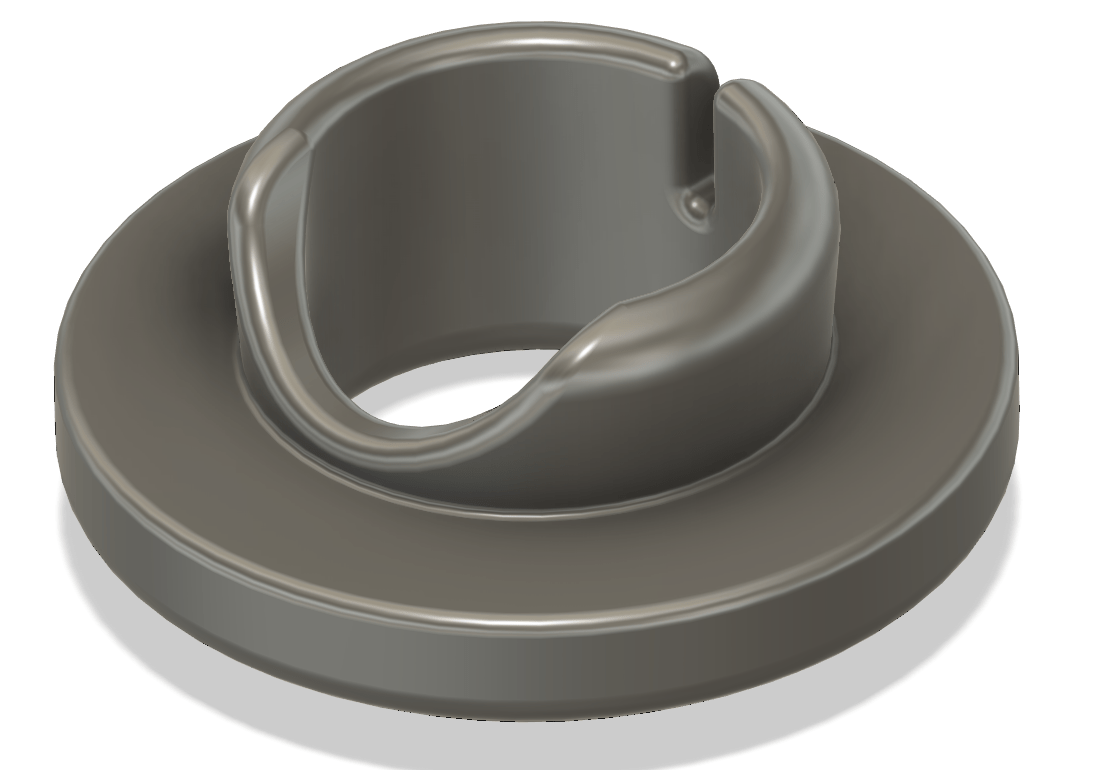

"This design is a grommet washer to protect wires protruding through the bottom plate, typically done with mains wiring"

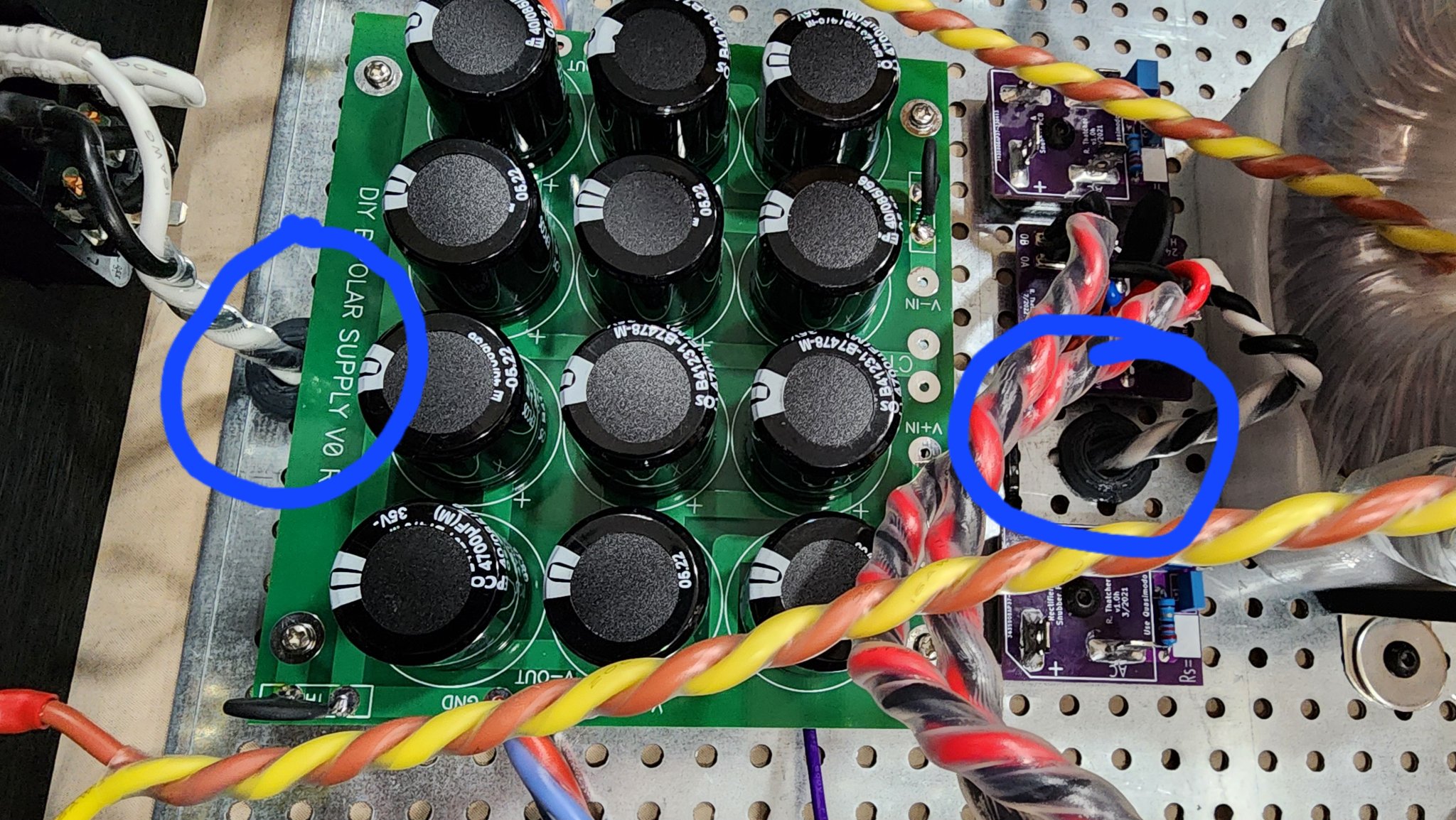

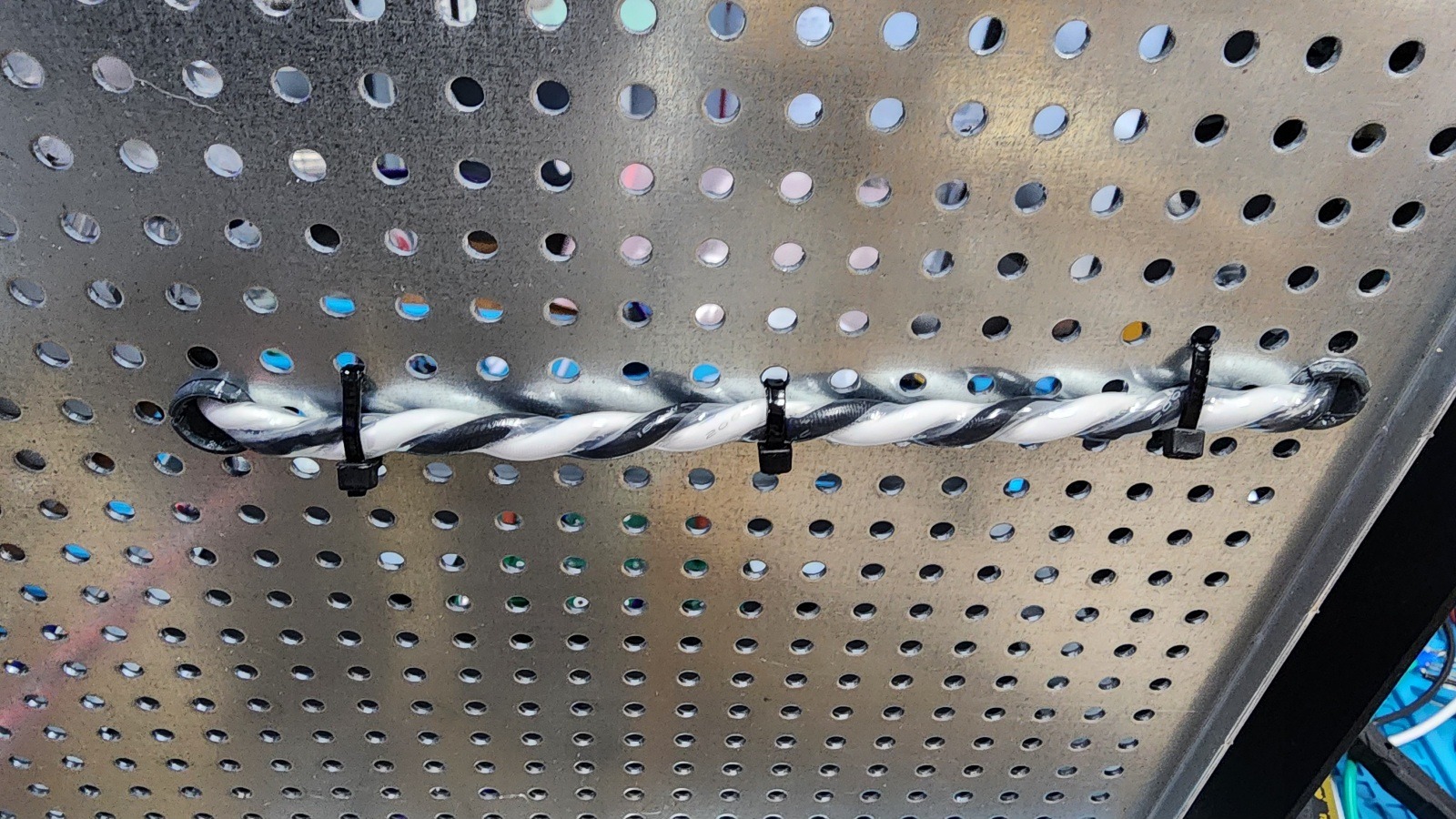

This is a very simple design to provide a 3D print grommet that "snaps" into a 12mm (or 1/2 inch for Version 2) hole drilled into the bottom perforated mounting plate for Modushop (or any metal plate for that matter) chassis. Instead of using the "lip up" approach to the bottom plate, which allows for mains wiring to sneak underneath from back to front, you can use the "lip down" approach (slightly less restrictive for mounting) and instead drill two large holes at the front and back of the plate. The grommets purpose is nothign more than to protect the mains wires from abraision damage which could potentially results in a mains-to-ground short if the insulation were to become damaged. There are two versions I've created. Version 1 for a 12mm hole (I used a 15/32 drill bit) whereas version 2 is for a slightly larger 1/2 inch hole (not yet confirmed it fits, but the dimensions implies it'll work fine).

I've included a zip file for each of the two versions that includes both STL and 3MF files. Happy to tweak the design for other hole diameters via a PM request with actual measurements, and post a new version. I've also included the current Fusion 360 file so anyone can modify the part to the hole size they desire (just know it may require tweaks to the design based on fillet dimensions used). Please post modifications here so others can benefit from your design tweaks/updates/remixes.

Printing Instructions

Install Instructions

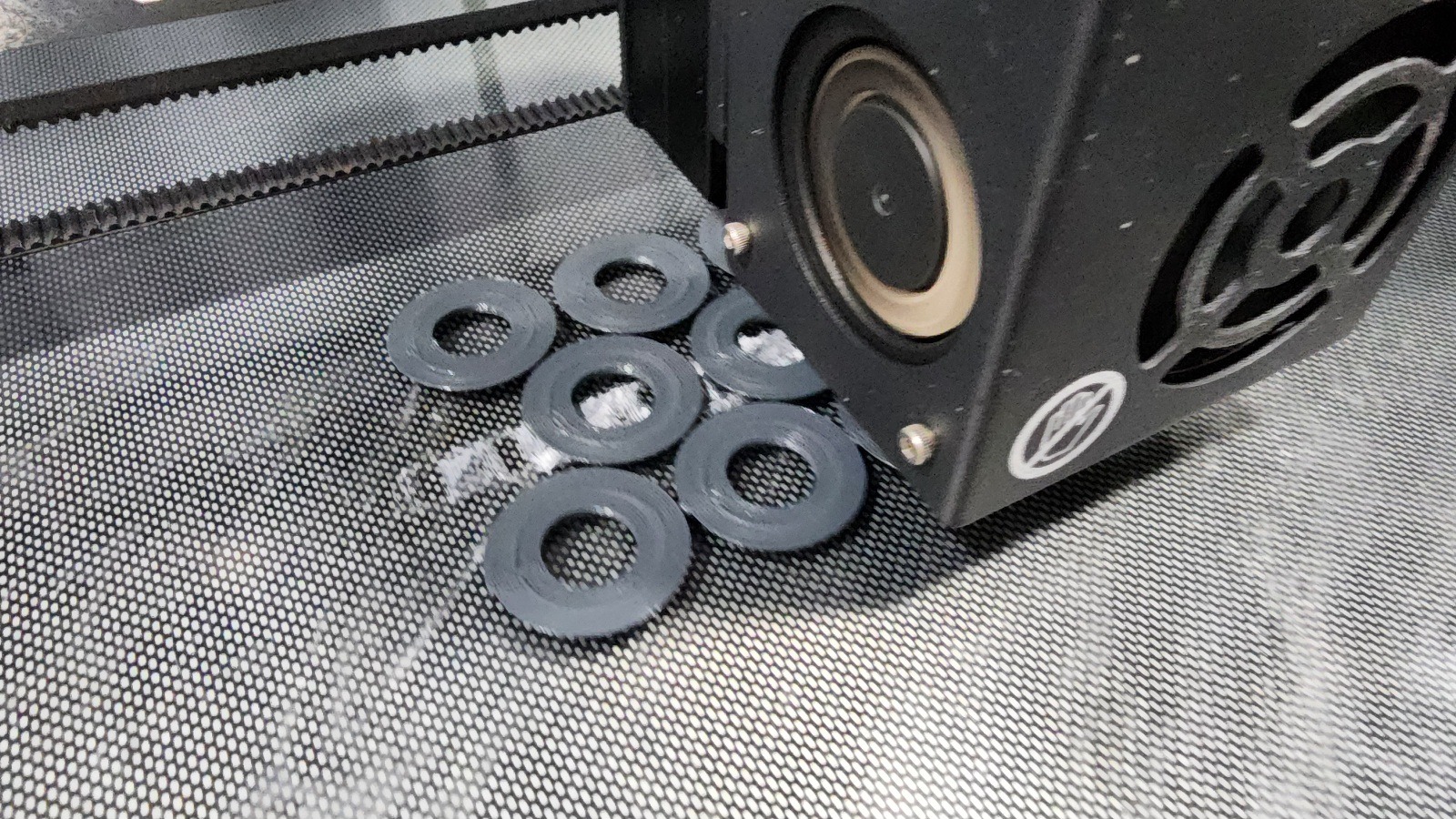

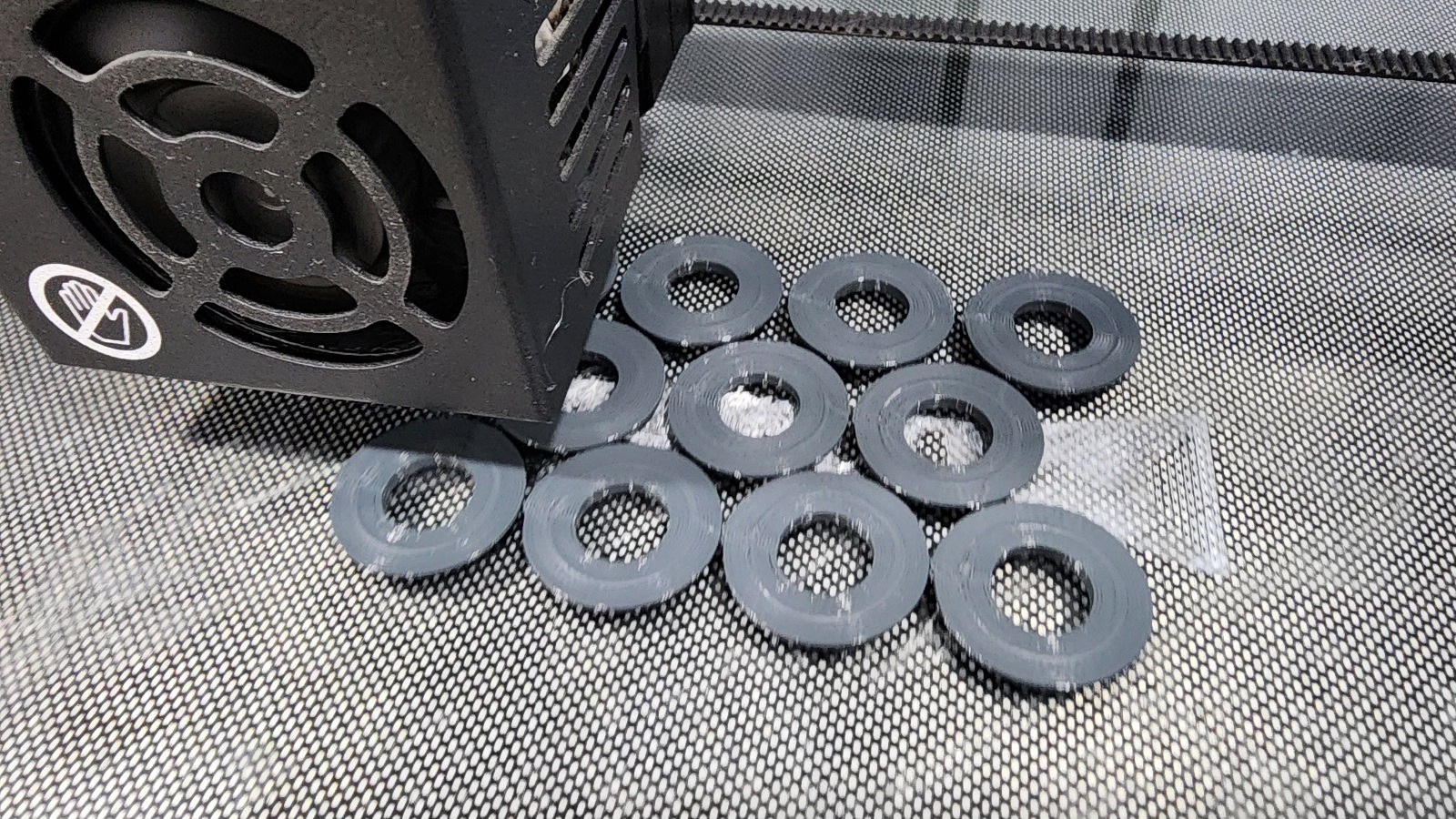

Finished product...

This is a very simple design to provide a 3D print grommet that "snaps" into a 12mm (or 1/2 inch for Version 2) hole drilled into the bottom perforated mounting plate for Modushop (or any metal plate for that matter) chassis. Instead of using the "lip up" approach to the bottom plate, which allows for mains wiring to sneak underneath from back to front, you can use the "lip down" approach (slightly less restrictive for mounting) and instead drill two large holes at the front and back of the plate. The grommets purpose is nothign more than to protect the mains wires from abraision damage which could potentially results in a mains-to-ground short if the insulation were to become damaged. There are two versions I've created. Version 1 for a 12mm hole (I used a 15/32 drill bit) whereas version 2 is for a slightly larger 1/2 inch hole (not yet confirmed it fits, but the dimensions implies it'll work fine).

I've included a zip file for each of the two versions that includes both STL and 3MF files. Happy to tweak the design for other hole diameters via a PM request with actual measurements, and post a new version. I've also included the current Fusion 360 file so anyone can modify the part to the hole size they desire (just know it may require tweaks to the design based on fillet dimensions used). Please post modifications here so others can benefit from your design tweaks/updates/remixes.

Printing Instructions

- No need for supports. No brim needed if you use a good "sticky approach" to bed adhesion (I use a glue stick).

- Ensure the print is solid by increasing wall count appropriately (aka, no "fill")

Install Instructions

- Drill the appropriate holes in your chassis where you want the mains wiring (or any wiring you want to run under the plate) to go (12mm or 1/2in based on available drill bit sizes and "version")

- You simply "snap" the grommet washer into place from the top down using a significant amount of pressure (a hammer may be required to snap it in depending on how accurate your drilled hole is). It's a very solid "lock" into the hole (zero adhesive of any type required).

- Note that this design is DIRECTIONAL in how it's installed, and the crescent shaped cut out is where the wire bends at and turns toward the next protrusion, so pay close attention as you snap it into place. Once it's in, it's difficult to rotate orientation (not impossible, but not easy...requires a pliers)

- Now you can run your wires down through the perforated plate knowing they won't be damaged by the sharp metal edges on the hole.

Finished product...

Attachments

Last edited:

Rubber grommets are used throughout the industry and very inexpensive, compared to a hard plastic printed extrusion, that has to be hot glued on.

The glue lets go removing any strain relief from the wire.

https://uk.rs-online.com/web/p/cable-grommets/1614105?gb=s

https://uk.rs-online.com/web/p/cable-grommets/0543282?gb=s

Not so much fun though.😉

The glue lets go removing any strain relief from the wire.

https://uk.rs-online.com/web/p/cable-grommets/1614105?gb=s

https://uk.rs-online.com/web/p/cable-grommets/0543282?gb=s

Not so much fun though.😉

Zero glue required just FYI. I never mentioned needing any glue in the post so I'm not sure why it was assumed that was required. These snap in and hold secure. I had to cut the first design out with a diagonal cutters because it was so snug I couldn't get it out. Nothing against "industry standard", just providing an alternate, less expensive method. This is, after all, do it yourself approach.

The "hard" PLA is obviously not as compliant as a rubber grommet, but these designs are much (orders of magnitude) cheaper if you have access to a 3D printer and specifically designed for the purpose of protruding through a Modushop chassis plate (or similar). The cost to make a grommet per the design provided is around 5-10 cents US for the PLA material used (1.6 grams PLA per grommet). I am posting simply as a means to save funds, get a part quick (if you have a printer) and have access to a design that you can customize to hole size. I totally agree that rubber grommets work just as well, just 200x the cost based on the options posted above.

Additionally, you can print with TPU (similar in compliance to rubber), but I used PLA as it's more accessible and easier to print for most folks with a 3D printer. If you want to print with TPU, you'll need a direct drive 3D printer extruder.

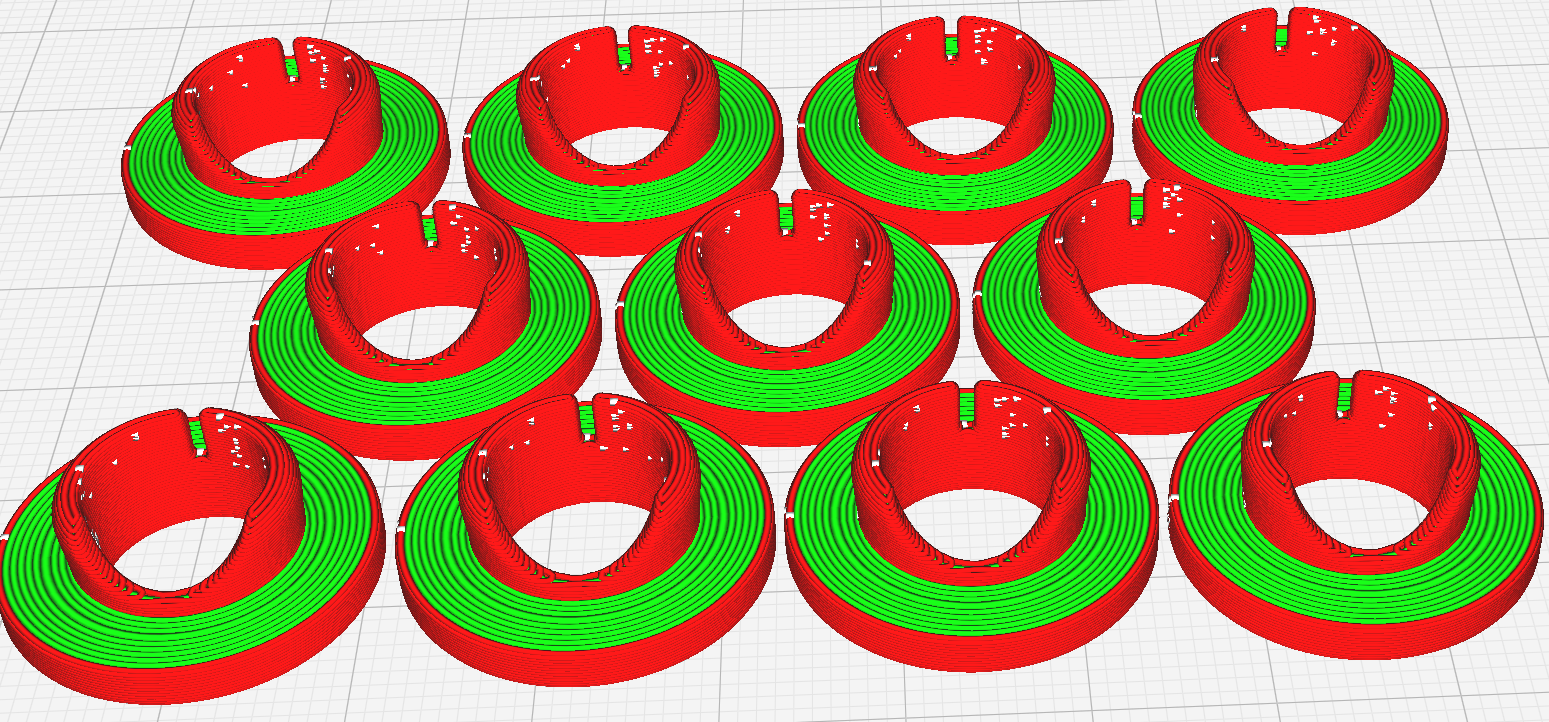

You can make a dozen at a time if you wish. Here's 10 at a time taking only 16g of material (1.6 grams each).

The "hard" PLA is obviously not as compliant as a rubber grommet, but these designs are much (orders of magnitude) cheaper if you have access to a 3D printer and specifically designed for the purpose of protruding through a Modushop chassis plate (or similar). The cost to make a grommet per the design provided is around 5-10 cents US for the PLA material used (1.6 grams PLA per grommet). I am posting simply as a means to save funds, get a part quick (if you have a printer) and have access to a design that you can customize to hole size. I totally agree that rubber grommets work just as well, just 200x the cost based on the options posted above.

Additionally, you can print with TPU (similar in compliance to rubber), but I used PLA as it's more accessible and easier to print for most folks with a 3D printer. If you want to print with TPU, you'll need a direct drive 3D printer extruder.

You can make a dozen at a time if you wish. Here's 10 at a time taking only 16g of material (1.6 grams each).

Last edited:

Printing 10 qty at a time. Total cost of materials is $10/1000grams for the cheap PLA I buy, so that's $0.16 for 10 grommets. That's less than 2 cents per grommet!! I have confirmed that they work great. That's over 900 times cheaper than rubber grommets posted above.

Last edited:

Commercial product, so perhaps search for 'flexible edging'. The product I have has a cat number KG016WT.

The advantage is that it suits nearly all holes/cutouts - just cut and fit to suit.

The advantage is that it suits nearly all holes/cutouts - just cut and fit to suit.

All I got with my search was gardening products. A link would help if possible. The part number "KG016WT" did not provide much either. I like the simple design and universal approach that's independent of hole diameter. Hard to beat 2 cents per hole protected, but a cheap universal solution that's available for all is ideal.

If this is something not easily found (like on Amazon), I could try to replicate it in a 3D print, but it's just hard to justify the approach when it's so easy to update the "grommet' design to accommodate different diameter holes on the cheap with in house prints. We're talking a few cents for a part for those with a 3D printer. The whole point of this thread is being able to print a part for wire safety at home for crazy cheap. For those who can't print a part, I'm hoping any alternatives presented here are easily attainable.

The whole point of offering up 3D print designs for diyaudio is to offer either significantly cheaper options, or something that can be made which is hard to find. There's no reason to "make" if a part is cheaper and more accessible to "buy". I always go to the latter if it's available.

If this is something not easily found (like on Amazon), I could try to replicate it in a 3D print, but it's just hard to justify the approach when it's so easy to update the "grommet' design to accommodate different diameter holes on the cheap with in house prints. We're talking a few cents for a part for those with a 3D printer. The whole point of this thread is being able to print a part for wire safety at home for crazy cheap. For those who can't print a part, I'm hoping any alternatives presented here are easily attainable.

The whole point of offering up 3D print designs for diyaudio is to offer either significantly cheaper options, or something that can be made which is hard to find. There's no reason to "make" if a part is cheaper and more accessible to "buy". I always go to the latter if it's available.

Last edited:

Perhaps a better search term is 'nylon moveable bushing'. Lots of outlets related to Australia, but also some links to other countries, including amazon:

https://www.amazon.com/uxcell-Movable-Protector-2-2mm-3mm-Thickness/dp/B083TKVC3J

https://www.amazon.com/uxcell-Movable-Protector-2-2mm-3mm-Thickness/dp/B083TKVC3J

"Zero glue required just FYI. I never mentioned needing any glue in the post so I'm not sure why it was assumed that was required. These snap in and hold secure. I had to cut the first design out with a diagonal cutters because it was so snug I couldn't get it out. Nothing against "industry standard", just providing an alternate, less expensive method. This is, after all, do it yourself approach.

The "hard" PLA is obviously not as compliant as a rubber grommet, but these designs are much (orders of magnitude) cheaper if you have access to a 3D printer and specifically designed for the purpose of protruding through a Modushop chassis plate (or similar). The cost to make a grommet per the design provided is around 5-10 cents US for the PLA material used (1.6 grams PLA per grommet). I am posting simply as a means to save funds, get a part quick (if you have a printer) and have access to a design that you can customize to hole size. I totally agree that rubber grommets work just as well, just 200x the cost based on the options posted above.

Additionally, you can print with TPU (similar in compliance to rubber), but I used PLA as it's more accessible and easier to print for most folks with a 3D printer. If you want to print with TPU, you'll need a direct drive 3D printer extruder.

You can make a dozen at a time if you wish. Here's 10 at a time taking only 16g of material (1.6 grams each).

View attachment 1287062

Printing Instructions

- No need for supports. No brim needed if you use a good "sticky approach" to bed adhesion (I use a glue stick).

- Ensure the print is solid by increasing wall count appropriately (aka, no "fill")"

Misread it obviously.

Ahh, ok I see the confusion. I use a kids glue stick on the printer bed so parts that have very little contact area with the bed don't break away mid print and turn into a spaghetti mess, or worse, a melted blob that clogs the printer nozzle.

The other option is a "brim", which adds a bunch of area on the build plate to help hold it down, but that means you have to cut the brim away after the print is done (similar to flashing), which is a hassle and leaves a line where it was cut away.

The other option is a "brim", which adds a bunch of area on the build plate to help hold it down, but that means you have to cut the brim away after the print is done (similar to flashing), which is a hassle and leaves a line where it was cut away.

- Home

- Design & Build

- Parts

- Chassis Plate Mains AC Wire Protection - Mains protrusion through the perforated plate.