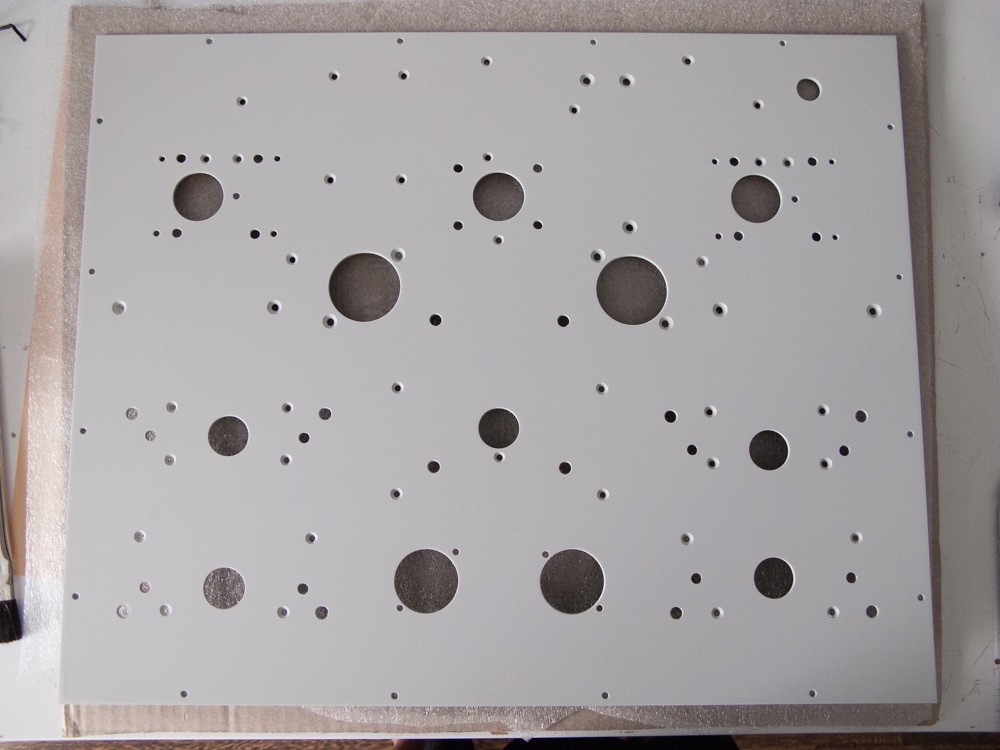

I drew up a 2d plan for the holes I need to drill for a tube amp. At first I was planning to mark up the metal for drilling with a ruler and compass, but I saw a video using a much easier technique where the plan is printed to scale and then glued on the metal and then drilled. Then the paper is removed after drilling is finished.

I assume this is a common technique so I wanted to ask what kind of glue is used and how is the paper removed afterwards?

I assume this is a common technique so I wanted to ask what kind of glue is used and how is the paper removed afterwards?

I usually cover the panel with masking tape, them mark the points to drill. The advantage is the masking tape protects the surface from damage while drilling / filing.

For me making a paper print or taping the chassis is an extra unnecessary step. I prefer to measure the X and Y coordinates and mark them on the chassis with a fine felt tip pen. No need to draw circles, just mark a small x to center punch from. Establish socket mounting holes with the socket itself after chassis punching the hole. Likewise with transformers and other parts. Any ink left wipes right off with a paper towel moistened with alcohol.

Wood glue D2 type works fine for gluing a paper template to metal .

Hope this helps , regards F.

Ad: remove paper and glue with water when finished .

Hope this helps , regards F.

Ad: remove paper and glue with water when finished .

Last edited:

A long ago I used Bishop-Graphics to make PCB designs into a mylar grid sheet, marked in inches (0.1 inch minimum), now I make PCB with the PC, but mylar foils are great to pass the drilling pattern to the metal plate.

I paint the metal with blue pattern makers liguid the scratch in the locations to be drilled. I don't scratch the metal just the blue. Then wash off the blue when done

sent from cell

sent from cell

I saw a video using a much easier technique where the plan is printed to scale and then glued on the metal and then drilled.

Some printers lack an accurate 1:1 scaling, so check this carefully. I would tape the printout in place, and center punch all the holes

before drilling. Larger holes should have a smaller pilot hole drilled first, to improve the accuracy of location.

Larger holes should have a smaller pilot hole drilled first, to improve the accuracy of location.

This is very important, in addition to improve the accuracy of hole location, it helps with the geometry of holes, it can sound crazy but it is difficult to make a hole perfectly round.

I assume this is a common technique so I wanted to ask what kind of glue is used and how is the paper removed afterwards?

I use Easy-Tack Adhesive: Easy-Tack Repositionable Adhesive - | Krylon.

I adhere a blank piece of paper on the metal plate and then draw out the holes and drill points using a pencil and ruler.

Once all the holes have been cut and drilled, I remove the paper with some goo-gone: Amazon.com: Goo Gone - 2oz Bottle - Citrus Scented.

Then clean with soap and water.

This is very important, in addition to improve the accuracy of hole location, it helps with the geometry of holes,

it can sound crazy but it is difficult to make a hole perfectly round.

Using a drill press does help.

I used blue masking tape. Completely covered the chassis (use wide tape) then used a fine pen to mark it. I used different colours for different diameter holes.

I've been using an old DOS-based version of AutoCAD since 1988. I have an (equally old) 8-pen plotter which is calibrated and plot out 1:1 templates on thicker plotter paper. I then lightly scribe the edges with an exacto knife, fold down the sides and use masking tape to secure to the chassis. I also put a full masking tape cover on the chassis, it provides protection for the chassis while drilling, allows me to easily mark off holes as I drill them out (all holes start with a 1/16-inch pilot) and then use Greenlee punches for the tube sockets and such. I still use the old Adel nibbler for square holes and finish up with a file. Using CAD allows me to quickly make up mirrored chassis as well.

Regards, KM

Regards, KM

Just to know, how do you do the holes?

Up to now for aluminium I've always used a drill with wood tips, all manual...

What kind os instruments do you use to drill?

Thanks

Up to now for aluminium I've always used a drill with wood tips, all manual...

What kind os instruments do you use to drill?

Thanks

Up to now for aluminium I've always used a drill with wood tips, all manual...

Using drill bit for wood is a great idea to make holes in aluminium, I use a low speed and lots of alcohol as lubricant, although I never gone more than 3 mm thick, always with a small pilot hole of course.

I guess I'm "oldschool". I draw the whole thing out on graph paper with a pencil and circle templates where needed, tape that to the chassis in several places around the edge, mark the centers of all holes with a hammer and a punch, then remove the paper from the chassis carefully, and using the paper as a guide for hole sizes, I then fabricate the chassis. If the design is from a software, you can print it as long as you verify that it's exactly to scale.

ust to know, how do you do the holes?

I use 1/16" bit for pilot holes plus a 1/8" to enlarge. After that I use "step" bits.

Print out your design and carefully check the printed dimensions.I use Easy-Tack Adhesive: Easy-Tack Repositionable Adhesive - | Krylon.

I adhere a blank piece of paper on the metal plate and then draw out the holes and drill points using a pencil and ruler.

Once all the holes have been cut and drilled, I remove the paper with some goo-gone: Amazon.com: Goo Gone - 2oz Bottle - Citrus Scented.

Then clean with soap and water.

If necessary rescale the print out to obtain correct dimensions.

Lightly spray the back of the paper with aerosol adhesive (available from art shops) and adhere to the work piece.

Too much aerosol adhesive can cause/allow the paper to soften and distort - thicker paper/card may be of benefit.

Recheck dimensions/geometry and allow to dry.

Center punch, then drill pilot holes for all perforations, and size up in steps as required - a step drill is very useful.

Remove paper sheet and clean work piece as required with white spirits solvent.

Deburr holes as required and you are good to go.

Dan.

I use 1/16" bit for pilot holes plus a 1/8" to enlarge. After that I use "step" bits.

The only way to fly with hand drill, altho' I just use the 1/8". Don't know what you're calling "wood drills" but those are generally Brad Point and not too good for metal. Not too good for the Brad Point either. I use the 1/8" DeWalt "Speed Tip Titanium" in card packs at the local Lowe's. A new one for each project.

Drill press for everything and TWO clamps on the workpiece (OK, sometimes I cheat) for the larger holes.

Since it hasn't been mentioned here yet... there is a really neat trick to transfer the ink of your printout directly to metal. All you need is a laser printer and acetone.

I did this the other day when I decided to save some money and make my own spade plugs out of pure nickel:

Simply draw your design in your favorite program, and print it out mirrored on a laser printer (I don't think ink-printers work for this, haven't tried though). Make sure it is to scale.

Then put the paper with the ink down onto your metal, secure it so that it is in perfect position, then wipe some acetone over it. It's surprisingly simple!

Here is a video where you can see it done:

https://www.youtube.com/watch?v=VwxKE63QkMI

Acetone is nasty stuff, so wear gloves and a respirator, or do it in a well ventilated room.

I did this the other day when I decided to save some money and make my own spade plugs out of pure nickel:

An externally hosted image should be here but it was not working when we last tested it.

Simply draw your design in your favorite program, and print it out mirrored on a laser printer (I don't think ink-printers work for this, haven't tried though). Make sure it is to scale.

Then put the paper with the ink down onto your metal, secure it so that it is in perfect position, then wipe some acetone over it. It's surprisingly simple!

Here is a video where you can see it done:

https://www.youtube.com/watch?v=VwxKE63QkMI

Acetone is nasty stuff, so wear gloves and a respirator, or do it in a well ventilated room.

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- Chassis drilling techniques