from https://audioxpress.com/news/produc...oustic-analysis-in-audioxpress-september-2023 :

This pic of it showed up among the 2022 winners here: https://www.parts-express.com/speaker-design-competition I understand the use of the wire frame, but WAF, in my house, would be low. Perhaps wrapping them with a neutral or artistic/fun acoustically transparent fabric could gain higher acceptance. For me, this approach would only be useful in development.

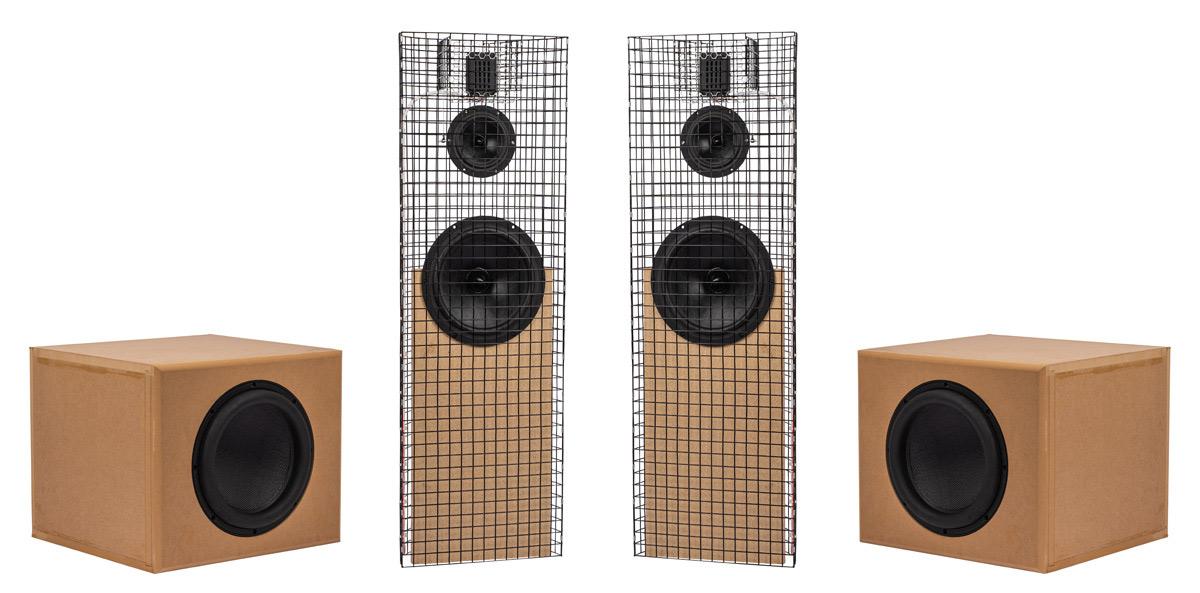

And on the home audio front, Charlie Laub explains how he designed a Minimally Baffled Dipole Loudspeaker. After experimenting with and building open baffle speakers for more than 10 years, in this article he reviews the related theory and the approach to practical design and construction, followed the crossover design and voicing equalization. The project is based on the example design "Baffle-less-ness" that garnered first place in the Open Unlimited category at the 2022 Speaker Design Competition (Midwest Audio Fest).

This pic of it showed up among the 2022 winners here: https://www.parts-express.com/speaker-design-competition I understand the use of the wire frame, but WAF, in my house, would be low. Perhaps wrapping them with a neutral or artistic/fun acoustically transparent fabric could gain higher acceptance. For me, this approach would only be useful in development.

My article is primarily about the concept behind building a speaker this way, and contains a good amount of theory, background, and motivation in part 1 that is appearing in the September issue of audioXpress. To demonstrate the concept I built a prototype. It is not the speaker shown above. I did not include this image or any mention of that particular speaker in my submission to audioXpress, and the concept had evolved beyond that by the time I submitted the article, which was almost a year ago now. For some reason unknown to me, when I received my author proof the editors had chosen this image to use at the beginning of the article when it was clear that was not the speaker I was talking about. It was a bit shocking because it is actually an example of how NOT to layout the drivers. This text:

The most obvious feature of these sorts of builds is the coated welded-wire mesh I use to suspend the midrange and tweeter. It's is actually a PERFECT solution that meets the needs of what I am trying to do. It is an acoustically transparent, supporting structure for these drivers. Because it has a vinyl coating the resonances in the wire mesh are nicely damped out and it is quite acoustically dead. I did not see a reason to "dress it up" with speaker fabric and I need access to the drivers inside when transporting or moving it, etc. It is material I was able to purchase, shape, and join into the support and was much better than other concepts for supporting the drivers that I have tried in the past. And it fits the requirement of not being a baffle nicely, but then it is also just what it is and not some piece of wood that can be nicely finished. I would like to find a way to create an equivalent structure but in a more finished and artistic way. As long as it can perform the function of supporting the driver while being acoustically transparent it could be anything. I can only envision that as being comprised of thin metal elements, but the shape could be anything you could imagine as long as you can fabricate that.

is what they came up with, not my words. After waiting 9 months to get this in print I was not going to throw up any barriers to them, so I just left it alone. Although the prototype speaker I built for the article also uses MDF for the woofer panel, how it LOOKS is not part of the proof of concept. Build it however you like it, should you want to do that.The project is based on the example design "Baffle-less-ness" that garnered first place in the Open Unlimited category at the 2022 Speaker Design Competition (Midwest Audio Fest).

The most obvious feature of these sorts of builds is the coated welded-wire mesh I use to suspend the midrange and tweeter. It's is actually a PERFECT solution that meets the needs of what I am trying to do. It is an acoustically transparent, supporting structure for these drivers. Because it has a vinyl coating the resonances in the wire mesh are nicely damped out and it is quite acoustically dead. I did not see a reason to "dress it up" with speaker fabric and I need access to the drivers inside when transporting or moving it, etc. It is material I was able to purchase, shape, and join into the support and was much better than other concepts for supporting the drivers that I have tried in the past. And it fits the requirement of not being a baffle nicely, but then it is also just what it is and not some piece of wood that can be nicely finished. I would like to find a way to create an equivalent structure but in a more finished and artistic way. As long as it can perform the function of supporting the driver while being acoustically transparent it could be anything. I can only envision that as being comprised of thin metal elements, but the shape could be anything you could imagine as long as you can fabricate that.

This stuff:

https://fencerwire.com/14-gauge-black-vinyl-coated-welded-wire-mesh-size-1-inch-by-1-inch/

It comes in rolls. Get the 4 foot wide roll. To make the support cage you cut off strips, flatten or shape them, and then join them back together. Practical shapes include a "D" cross section with two pieces or a "Δ" shape (e.g. the delta symbol, like a triangle) using three sections.

To mechanically join the wire panels I used these things called "wire cage buckle clips". I got them from Amazon :

https://www.amazon.com/Chicken-Wire-Cage-Clips-Installation/dp/B0B6BXJN56/ref=sr_1_6

They are not the easiest things to use, but they work pretty well. The results is a stiff and sturdy structure. I even hung 12" and 15" drivers and the 14 gauge wire can support quite a lot of weight.

The hanging lines are monofilament nylon. If you get 100-200 pound test, the diameter of the nylon is similar to 18 or 16 gauge wire. I crimped forked terminals onto the nylon and then bent the fork over one of the wires. This makes a convenient way to hang the wire and you can easily reposition where this hangs off the frame. On the other end I crimped on a ring terminal. To hang the midrange you first put to long bolts or screws through two of the mounting holes. The bolts need to be long enough to at least reach the top plate or magnet of the motor. This is where the center of mass of the driver is located. Fasten the two bolts or screws to the driver mounting frame tightly (I used a wing nut and a washer). Then slide the ring terminal over the free end of the fastener to about where the center of mass is located. Once you find the balance point you can keep the ring terminal there with two additional nuts, one on each side. Then you just hang the driver using the forked terminals on the other end of the two nylon hanging lines. There is a picture of this in part 1 of the article (Photo 1). It shows some additional cross braces that I installed as convenient mounting points for the midrange and tweeter.

https://fencerwire.com/14-gauge-black-vinyl-coated-welded-wire-mesh-size-1-inch-by-1-inch/

It comes in rolls. Get the 4 foot wide roll. To make the support cage you cut off strips, flatten or shape them, and then join them back together. Practical shapes include a "D" cross section with two pieces or a "Δ" shape (e.g. the delta symbol, like a triangle) using three sections.

To mechanically join the wire panels I used these things called "wire cage buckle clips". I got them from Amazon :

https://www.amazon.com/Chicken-Wire-Cage-Clips-Installation/dp/B0B6BXJN56/ref=sr_1_6

They are not the easiest things to use, but they work pretty well. The results is a stiff and sturdy structure. I even hung 12" and 15" drivers and the 14 gauge wire can support quite a lot of weight.

The hanging lines are monofilament nylon. If you get 100-200 pound test, the diameter of the nylon is similar to 18 or 16 gauge wire. I crimped forked terminals onto the nylon and then bent the fork over one of the wires. This makes a convenient way to hang the wire and you can easily reposition where this hangs off the frame. On the other end I crimped on a ring terminal. To hang the midrange you first put to long bolts or screws through two of the mounting holes. The bolts need to be long enough to at least reach the top plate or magnet of the motor. This is where the center of mass of the driver is located. Fasten the two bolts or screws to the driver mounting frame tightly (I used a wing nut and a washer). Then slide the ring terminal over the free end of the fastener to about where the center of mass is located. Once you find the balance point you can keep the ring terminal there with two additional nuts, one on each side. Then you just hang the driver using the forked terminals on the other end of the two nylon hanging lines. There is a picture of this in part 1 of the article (Photo 1). It shows some additional cross braces that I installed as convenient mounting points for the midrange and tweeter.

Now that both parts of the article have been published I wanted to follow up on some comments I have received regarding the large amount of voicing EQ (9dB) that I used for this project. It's s very unusual to use that much voicing correction, but it did sound best based on extensive listening tests that I performed. It turns out this is a consequence of how I conducted the measurements for the system.

Measurements of the woofer panel and mid+tweeter were performed under different "field conditions". The woofer panel measurement included the groundplane reflection and was designed to take advantage of it for gain, so it is a "half-space" (2pi steradians) measurement. The mid and tweeter are measured in free field conditions, so even when I adjust for the different measurement distances a different acoustical dimension or "space" is seen for these two measurement conditions.

What I realized later is that the ground plane gain causes the measured SPL to be elevated. This would be by 6dB if you assume full gain from the ground. In my aX article I used the measured data and created a flat system frequency response, meaning that the woofer level is actually too low by about 6dB with respect to the free field conditions used for the mid and tweeter. This is why the voicing EQ is so high at 9dB - it includes the 6dB of extra low frequency gain for the woofer panel so that the in-room tonal balance is about right.

I only figured this out later when I started using a very steep crossover in a different loudspeaker build. It didn't sound right around the woofer to midrange crossover point without using some very sharply changing voicing EQ corrections in that region. So I used a new approach - I converted this woofer panel measurement into "free field" conditions by reducing the measured data SPL by about 6dB. After that, I found that 3-4dB was an appropriate amount of voicing EQ, which is more in the "normal" range.

For loudspeaker described in my aX article I had assumed that the floor gain would always be present in the listening space and so I should use a 2pi measurement for the woofer panel when developing the crossover. But now I think that it is more correct to use a 4pi field representation for all measurements. It just happened to work out for the system in the aX article because I used a 2nd order low pass crossover filter around 300Hz for the woofer panel and its rolloff is slow/smooth. This allowed me to achieve the same effect with the 9dB voicing EQ curve that I could have achieved by first correcting the woofer panel response by 6dB. But when I was using a steeper filter at 300Hz there was too much energy in the 150-300 Hz region if the voicing EQ was smooth and gradual (which is should be) and I did not correct the woofer panel measurement from half space to free space.

I submitted my paper about 1 year ago to AudioXpress and since that time I have continued building speakers and learning new things, including what I describe above.

For more on what I call "field conditions" see this link for some info:

https://trueaudio.com/st_spcs1.htm

https://audiojudgement.com/speaker-spatial-loading/

Measurements of the woofer panel and mid+tweeter were performed under different "field conditions". The woofer panel measurement included the groundplane reflection and was designed to take advantage of it for gain, so it is a "half-space" (2pi steradians) measurement. The mid and tweeter are measured in free field conditions, so even when I adjust for the different measurement distances a different acoustical dimension or "space" is seen for these two measurement conditions.

What I realized later is that the ground plane gain causes the measured SPL to be elevated. This would be by 6dB if you assume full gain from the ground. In my aX article I used the measured data and created a flat system frequency response, meaning that the woofer level is actually too low by about 6dB with respect to the free field conditions used for the mid and tweeter. This is why the voicing EQ is so high at 9dB - it includes the 6dB of extra low frequency gain for the woofer panel so that the in-room tonal balance is about right.

I only figured this out later when I started using a very steep crossover in a different loudspeaker build. It didn't sound right around the woofer to midrange crossover point without using some very sharply changing voicing EQ corrections in that region. So I used a new approach - I converted this woofer panel measurement into "free field" conditions by reducing the measured data SPL by about 6dB. After that, I found that 3-4dB was an appropriate amount of voicing EQ, which is more in the "normal" range.

For loudspeaker described in my aX article I had assumed that the floor gain would always be present in the listening space and so I should use a 2pi measurement for the woofer panel when developing the crossover. But now I think that it is more correct to use a 4pi field representation for all measurements. It just happened to work out for the system in the aX article because I used a 2nd order low pass crossover filter around 300Hz for the woofer panel and its rolloff is slow/smooth. This allowed me to achieve the same effect with the 9dB voicing EQ curve that I could have achieved by first correcting the woofer panel response by 6dB. But when I was using a steeper filter at 300Hz there was too much energy in the 150-300 Hz region if the voicing EQ was smooth and gradual (which is should be) and I did not correct the woofer panel measurement from half space to free space.

I submitted my paper about 1 year ago to AudioXpress and since that time I have continued building speakers and learning new things, including what I describe above.

For more on what I call "field conditions" see this link for some info:

https://trueaudio.com/st_spcs1.htm

https://audiojudgement.com/speaker-spatial-loading/

- Home

- Loudspeakers

- Multi-Way

- CharlieLaub OB article in audioXpress Sept 2023