I'm using Cardas twisted pairs to wire an attenuator and am having trouble: seems the wire doesn't take to solder, doesn't conduct heat well (as if contaminated). I used flux and that helped, but still a problem. After this I sanded, better and added alcohol, but made little difference. How can I solve this problem? I have laquor thinner and acetone, would either help or hinder?

HELP! lol

thanks,

John

HELP! lol

thanks,

John

John,

Are you sure that the exact opposite of what you are saying isn't the problem? Could it be that the wire is dissipating the heat so fast that you need a large soldering iron? If the wire is copper take a few strands off and see if they can be soldered with a smaller amount of wire. I suspect that the gauge wire is rather large, just guessing as they are audiophile wires and that is usually the case. If the solder flows well with a small number of short pieces of wire you will have to increase the heat. Between the attenuator and the wire you may just be getting a cold solder joint.

Are you sure that the exact opposite of what you are saying isn't the problem? Could it be that the wire is dissipating the heat so fast that you need a large soldering iron? If the wire is copper take a few strands off and see if they can be soldered with a smaller amount of wire. I suspect that the gauge wire is rather large, just guessing as they are audiophile wires and that is usually the case. If the solder flows well with a small number of short pieces of wire you will have to increase the heat. Between the attenuator and the wire you may just be getting a cold solder joint.

I'm fairly sure Cardas uses a special coating on their wire and you have to remove the coating before soldering. Like a clear polyurethane or something like that. Some folks sand or Dremel tool brush it.

Yup...here you go...towards the bottom of page.

http://www.cardas.com/insights_why.php

"As each strand is drawn, the resultant ultra pure surface is immediately given a urethane enamel "Litz" coating."

Yup...here you go...towards the bottom of page.

http://www.cardas.com/insights_why.php

"As each strand is drawn, the resultant ultra pure surface is immediately given a urethane enamel "Litz" coating."

Last edited:

John,

If the speedracer is correct than you will need to do what he says and sand every strand of wire or you would need to use Methylene Chloride to dissolve a urethane coating. MC is rather nasty and strong but if you can get your hands on some it will dissolve the coating. Urethane is one of my specialties so I know this is the correct solvent. The solvents you are trying to use will not work, it has to be a chlorinated solvent.

Steven

If the speedracer is correct than you will need to do what he says and sand every strand of wire or you would need to use Methylene Chloride to dissolve a urethane coating. MC is rather nasty and strong but if you can get your hands on some it will dissolve the coating. Urethane is one of my specialties so I know this is the correct solvent. The solvents you are trying to use will not work, it has to be a chlorinated solvent.

Steven

You do not need to sand each individual strand, it's crazy. Yes each indiviual strand is enameled. All you need is either solder pot or strong soldering iron and you need to dip the end of the wire in the solder until enameling melts and the wire get tinned. You will notice it by yourself when it happens it is clearly visible. I do it easily with typical 75 Watt soldering iron. Once you prsctice it it is easy.

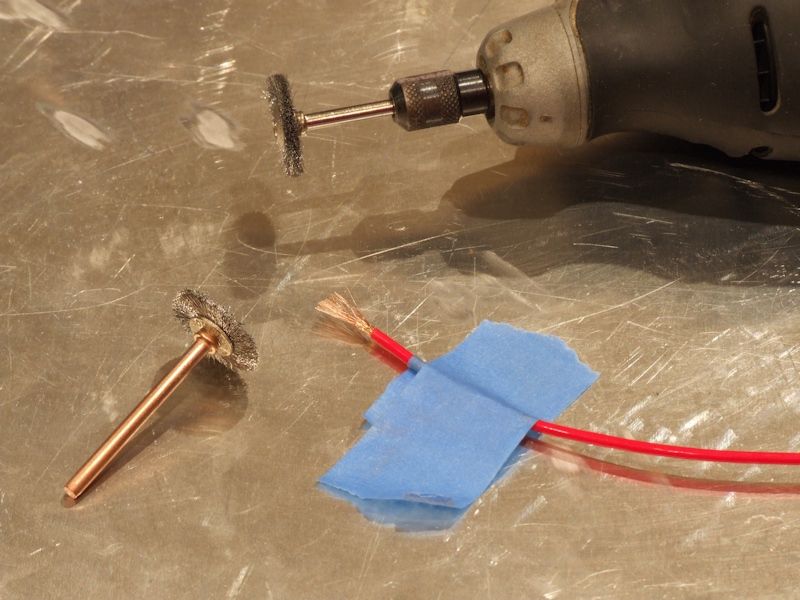

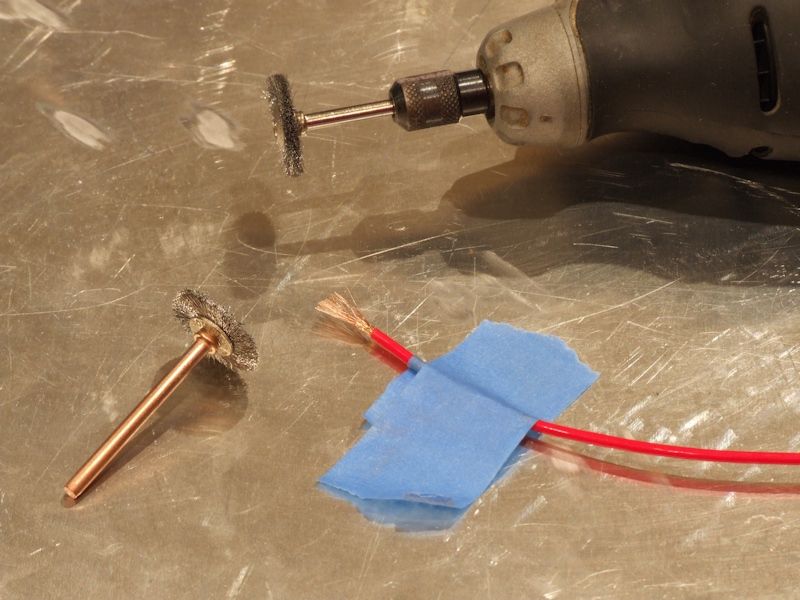

For what its worth....the Dremel wire wheel, use speed control and best wear safety glasses method.

Litz wire! each strand has a coating. a solder pot works best, burns that coating right off! otherwise some for of chemical stripper etc.

A small can of aircraft paint stripper would do the job. It is methylene chloride. You can find it at most home hardware stores in the paint section. Just keep it off the insulation as it will soften or swell that right up! Wash it after with clean water and then use acetone to drive off any water.

Thanks everyone! I figured as much, a coating on each strand ... so much fun. How does coating each strand help, I wonder?

As I don't have a solder pot (could rig one) and as I'm not keen on sanding and maybe the wire wheel method is a little harsh, I'll look for some methylene chloride tomorrow.

Again, thank you!

As I don't have a solder pot (could rig one) and as I'm not keen on sanding and maybe the wire wheel method is a little harsh, I'll look for some methylene chloride tomorrow.

Again, thank you!

I found this:

SLT-360 Solder Pot Titanium Alloy Soldering Melting Tin 38mm 100W $17.37 Free Shipping @GoodLuckBuy.com

wonder if it's worth waiting for (meaning, will it do the best job)?

Well, I can forget that, they're out to, I mean on holidays.

SLT-360 Solder Pot Titanium Alloy Soldering Melting Tin 38mm 100W $17.37 Free Shipping @GoodLuckBuy.com

wonder if it's worth waiting for (meaning, will it do the best job)?

Well, I can forget that, they're out to, I mean on holidays.

- Status

- Not open for further replies.

- Home

- Design & Build

- Parts

- Cardas Twisted Pairs