I am interested in film caps thermal stability.

I found, from a non official source.

Polystyrene - 120 ppm/℃

Polyester + 300

Polycarbonate +- 75

This must be out of date, polycarbonate doesn't exist anymore.

Where can I find, up to date data, from reliable sources ?

I found, from a non official source.

Polystyrene - 120 ppm/℃

Polyester + 300

Polycarbonate +- 75

This must be out of date, polycarbonate doesn't exist anymore.

Where can I find, up to date data, from reliable sources ?

Last edited:

If you can't find the specs I suggest you conduct the tests by yourself. I have a cromatography oven that I got for cheap on eBay to tests my circuits at different temperatures and measure how they drift, the thing weights a ton but it can go up to 80°C (176°F) and you can accurately set the temperature by one degree steps, you can measure several caps of the same brand/capacitance/model at different temperatures whilst monitoring the capacitance with an accurate LCR meter, then you can take the mean of your measurements and determine the ppm/°C of the cap, if the cap is small you may have to warm it up quite considerably so you can measure a difference.

Last edited:

Excellent tip.If you can't find the specs I suggest you conduct the tests by yourself. I have a cromatography oven that I got for cheap on eBay to tests my circuits at different temperatures and measure how they drift, the thing weights a ton but it can go up to 80°C (176°F) and you can accurately set the temperature by one degree steps, you can measure several caps of the same brand/capacitance/model at different temperatures whilst monitoring the capacitance with an accurate LCR meter, then you can take the mean of your measurements and determine the ppm/°C of the cap, if the cap is small you may have to warm it up quite considerably so you can measure a difference.

I think, I should invest in this for my project.

One of the problems with testing capacitor thermal changes with an oven is that there are also changes due to moisture ingress in the film!

So you might want to measure the capacitor dissipation and value before and after baking. To be really thorough then once again after sitting on the shelf for a year!

So you might want to measure the capacitor dissipation and value before and after baking. To be really thorough then once again after sitting on the shelf for a year!

SMD capacitors can have strange temperature sensitivity due to the PCB expansion putting mechanical stress on the part

WIMA polypropylene caps have the tempco in the datasheet: FKP 3 film/foil capacitors - WIMA – Competence in Capacitors gives a figure of "Temperature coefficient: -200 x 10-6/°C (typical)"

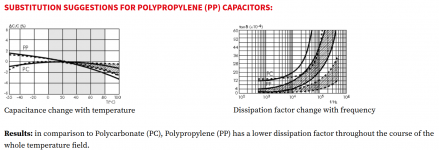

And then there are some Graphs here: Special technical subjects - WIMA – Competence in Capacitors (Look under "Substitution of obsolete polycarbonate (PC) capacitors")

Best regards,

Gunnar

And then there are some Graphs here: Special technical subjects - WIMA – Competence in Capacitors (Look under "Substitution of obsolete polycarbonate (PC) capacitors")

Best regards,

Gunnar

Attachments

Indeed, polycarbonate capacitors were of the best stability.

They don't exist anymore. We must do with substitutes.

It seems the substitutes are not as good.

They don't exist anymore. We must do with substitutes.

It seems the substitutes are not as good.

Last edited:

This is for a DC blocking cap.You may look at C0G ceramic. They have a factor of 20 - 100 lower Tc than film caps.

Jan

They say, ceramic makes distortion.

Ceramic is of low value, but I could block at the high impedance input of an op amp in non inverting mode.

May be, there is no problem using ceramic.

For coupling capacitors, the idea is they have a very low impedance at the frequencies of interest so the voltage across them is tiny and the distortion produced is insignificant.

Last edited:

Class II ceramic capacitors distort like crazy, but class I ceramics do not. NP0 a.k.a. C0G is a class I ceramic dielectric, in fact the most temperature stable class I dielectric (0 +/- 30 ppm/K). Its distortion is so small it is difficult to measure, like the distortion of good polypropylene and polystyrene film capacitors. SMD NP0 / C0G multilayer capacitors are available in values up to about 470 nF or 560 nF (in fairly big SMD packages).

Last edited:

- Home

- Design & Build

- Parts

- Capacitor Temperature Coefficient.