Re: Re: Whoa, Before You Go Too Far..........

I've seen such work done with a drill.

Also, I happen to run across the "Litz" cables that you made last year (because I was interesting in people's thoughts on Tefzel), seems you've been here (braiding cables, doing listening tests) before.

JF

Steve Eddy said:Otherwise I'd have to work up some sort of contraption to do the twisting...

I've seen such work done with a drill.

Also, I happen to run across the "Litz" cables that you made last year (because I was interesting in people's thoughts on Tefzel), seems you've been here (braiding cables, doing listening tests) before.

JF

Re: Re: Re: Whoa, Before You Go Too Far..........

Yes. That certainly saves time but I'm concerned with keeping a consistent pitch to the twist throughout the entire length. Also, this is enameled magnet wire and while the thin insulation is more robust than one would think, I've also some concern for the insulation using something as crude as a drill, as opposed to dedicated machines which maintain constant tensions, etc.

Yup. 🙂

I'd played a bit with magnet wire many years ago but all the stuff that was readily available to me at the time was the plain enamel type which doesn't solder well at all and doesn't strip well without dedicated equipment. So I just washed my hands of it.

I'm glad I came back to it though. However I'm using the solderable (they're even self-fluxing) wire which makes things much less fussy.

se

johnferrier said:I've seen such work done with a drill.

Yes. That certainly saves time but I'm concerned with keeping a consistent pitch to the twist throughout the entire length. Also, this is enameled magnet wire and while the thin insulation is more robust than one would think, I've also some concern for the insulation using something as crude as a drill, as opposed to dedicated machines which maintain constant tensions, etc.

Also, I happen to run across the "Litz" cables that you made last year (because I was interesting in people's thoughts on Tefzel), seems you've been here before.

Yup. 🙂

I'd played a bit with magnet wire many years ago but all the stuff that was readily available to me at the time was the plain enamel type which doesn't solder well at all and doesn't strip well without dedicated equipment. So I just washed my hands of it.

I'm glad I came back to it though. However I'm using the solderable (they're even self-fluxing) wire which makes things much less fussy.

se

Re: Re: Re: Re: Whoa, Before You Go Too Far..........

FWIW, I appreciate your attention to details (and research efforts...Bruno, Bob Pease, etc.).

JF

Steve Eddy said:That certainly saves time but I'm concerned with keeping a consistent pitch to the twist throughout the entire length.

...

I've also some concern for the insulation using something as crude as a drill, as opposed to dedicated machines which maintain constant tensions, etc.

FWIW, I appreciate your attention to details (and research efforts...Bruno, Bob Pease, etc.).

JF

Re: Re: Re: Re: Re: Whoa, Before You Go Too Far..........

Thank you for the kind words.

Though my attention to details has come back to bite me in the *** a number of times when I lost track of the forest for the trees. 🙂

Which is why it's always good to have people like yourself and others with a critical eye involved.

se

johnferrier said:FWIW, I appreciate your attention to details (and research efforts...Bruno, Bob Pease, etc.).

Thank you for the kind words.

Though my attention to details has come back to bite me in the *** a number of times when I lost track of the forest for the trees. 🙂

Which is why it's always good to have people like yourself and others with a critical eye involved.

se

Re: Re: Re: Re: Re: Re: Whoa, Before You Go Too Far..........

: )

JF

Steve Eddy said:Thank you for the kind words.

: )

JF

DIY Inductance Measurements

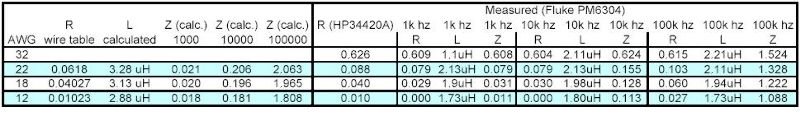

The attached graph shows some realistic inductance/reactance values for four 6' long wires: 32, 22, 18, and 12 AWG. I had indicated in another thead (now closed) that I would make some measurements. The only intent here is to provide real values.

Both meters are within their calibration periods. The 32 AWG wire is silver plated OFC. I didn't furnish calculations because I couldn't readily find the datasheet. The 22, 18, and 12 AWG wires are basic stranded wires.

I typed a longer explaination (that got lost when there was an error with the picture dimensions).

On the left is Z (calc.) 1000, 10000, and 100000 hertz. I used the formula L = 0.005 l (2.3 log10 (4 l/d - 0.75)). I made the calculations after the measurements. They all seem to jive. There may be errors and inaccuracies. This is only to provide ballpark figures (rather than joke figures).

JF

The attached graph shows some realistic inductance/reactance values for four 6' long wires: 32, 22, 18, and 12 AWG. I had indicated in another thead (now closed) that I would make some measurements. The only intent here is to provide real values.

Both meters are within their calibration periods. The 32 AWG wire is silver plated OFC. I didn't furnish calculations because I couldn't readily find the datasheet. The 22, 18, and 12 AWG wires are basic stranded wires.

I typed a longer explaination (that got lost when there was an error with the picture dimensions).

On the left is Z (calc.) 1000, 10000, and 100000 hertz. I used the formula L = 0.005 l (2.3 log10 (4 l/d - 0.75)). I made the calculations after the measurements. They all seem to jive. There may be errors and inaccuracies. This is only to provide ballpark figures (rather than joke figures).

JF

Attachments

Thread Jumping.............

Hi John, thanks for going to the trouble, and pity about the thread being closed prematurely.

Seeing as you have the appropriate gear, do you mind measuring some representative cables like standard fig 8 power cable and others.

It might be instructional for us all if Steve were to send you a length of the braided interconnects that he is making, and if I can talk him into twisted pair, these too.

Regards, Eric.

It might be wise to shift this stuff to a new thread say 'Real Cable Measurements' or something.....

Hi John, thanks for going to the trouble, and pity about the thread being closed prematurely.

Seeing as you have the appropriate gear, do you mind measuring some representative cables like standard fig 8 power cable and others.

It might be instructional for us all if Steve were to send you a length of the braided interconnects that he is making, and if I can talk him into twisted pair, these too.

Regards, Eric.

It might be wise to shift this stuff to a new thread say 'Real Cable Measurements' or something.....

Whoa, Before You Go Too Much Further.........

Originally posted by Steve Eddy

Well, when I said originally that I planned to use the braid, you had concerns about consistency of the braid. The braid even when done by hand is naturally more consistent and the pitch is more determined by the diameter of the wire than twisting is.

I have some concerns about things like work hardening of the wire, contaminants on the surface of the wires, tangles during the process causing kinks/discontinuities etc in the wires causing masking perhaps.

Don't forget that here we are trying to credibly establish audible directionality in inter-connects/wire so I feel that simple twisted pairs might be better for unbalanced interconnects - braided cables may help to mask the effect and then again braiding may emphasise the effect - dunno yet.

Frank has mentioned testing single strands, and I have encountered strong differences here also.

Because it's critical that the listeners not be able to determine direction by way of any visual clues, I'd personally feel more comfortable with the braid.

Hmmmm.

Frank and I are mature enough and honest enough to listen only and not bother to closely visually inspect the test wires or cables.

Otherwise I'd have to work up some sort of contraption to do the twisting that would assure consistency of the twisting that matched that of the braid done by hand.

A cup hook screwed into a far wall, a battery drill and an assistant is all that is required to make consistently twisted pair cables - ask for more details if you like.

Multiple sets of cable configurations (braided, twisted pair and single strand) ought to reinforce statistically positive findings.

Eric.

Originally posted by Steve Eddy

Well, when I said originally that I planned to use the braid, you had concerns about consistency of the braid. The braid even when done by hand is naturally more consistent and the pitch is more determined by the diameter of the wire than twisting is.

I have some concerns about things like work hardening of the wire, contaminants on the surface of the wires, tangles during the process causing kinks/discontinuities etc in the wires causing masking perhaps.

Don't forget that here we are trying to credibly establish audible directionality in inter-connects/wire so I feel that simple twisted pairs might be better for unbalanced interconnects - braided cables may help to mask the effect and then again braiding may emphasise the effect - dunno yet.

Frank has mentioned testing single strands, and I have encountered strong differences here also.

Because it's critical that the listeners not be able to determine direction by way of any visual clues, I'd personally feel more comfortable with the braid.

Hmmmm.

Frank and I are mature enough and honest enough to listen only and not bother to closely visually inspect the test wires or cables.

Otherwise I'd have to work up some sort of contraption to do the twisting that would assure consistency of the twisting that matched that of the braid done by hand.

A cup hook screwed into a far wall, a battery drill and an assistant is all that is required to make consistently twisted pair cables - ask for more details if you like.

Multiple sets of cable configurations (braided, twisted pair and single strand) ought to reinforce statistically positive findings.

Eric.

Re: Whoa, Before You Go Too Much Further.........

I trust you on that, but if there are any visual clues, you may

still see them and recognize them subconciously. Furthermore,

this subconscious process does not necessarily tell you the

right thing, since you are not aware of it and analyze it

properly. You could thus end up in a situation where your ears

actually do properly detect the direction, but your subconcious

interpretation of the visual clues gives a contradictory wrong

message that confuses your brain so you actually end up

failing the test although your ears passed it. That is not what

you want, I am sure.

mrfeedback said:

Frank and I are mature enough and honest enough to listen only and not bother to closely visually inspect the test wires or cables.

I trust you on that, but if there are any visual clues, you may

still see them and recognize them subconciously. Furthermore,

this subconscious process does not necessarily tell you the

right thing, since you are not aware of it and analyze it

properly. You could thus end up in a situation where your ears

actually do properly detect the direction, but your subconcious

interpretation of the visual clues gives a contradictory wrong

message that confuses your brain so you actually end up

failing the test although your ears passed it. That is not what

you want, I am sure.

Re: Whoa, Before You Go Too Much Further.........

The wires aren't really worked any more by braiding. The braid is ultimately just two interwoven twisted pairs. As for surface contaminants on the sufface of the wires, it's enameled wire. The wire sufrace is already protected. If you're worried about the surface of the enamel, are you going to be handling these with cotton gloves while you test them? As for the tangles, they're not causing any kinks/discontinuities. They don't get so tangled that the wires are bent to any degree. Not even as much as braiding or twisting. I make sure of that by addressing the tangles every few braids. It's a pain in the *** issue rather than a kinking/discontinuity issue.

How 'bout I just make up a braided set and a twisted set for the initial evaluation phase, where the directions are known?

I addressed this before. It's not about our trusting you and Frank not to peek. It's about the overall credibility of the test. That you simply COULD be able to determine direction by way of visual inspection would only undermine any positive result and could always be pointed to as a valid criticism and a source of ambiguity.

Again, this is enameled wire with a thin film insluation, not a thick, extruded thermoplastic. And while the enamel is a lot tougher than one would think, it's not nearly as robust as thick extruded thermoplastics.

How 'bout I just send you a set of each for the initial listening and you can report back which results in the more pronounced difference? Then we'll run the actual test with whatever that ends up being. If it's twisted, I'm willing to spend the extra time to try and keep the twists as consistent as possible.

se

mrfeedback said:I have some concerns about things like work hardening of the wire, contaminants on the surface of the wires, tangles during the process causing kinks/discontinuities etc in the wires causing masking perhaps.

The wires aren't really worked any more by braiding. The braid is ultimately just two interwoven twisted pairs. As for surface contaminants on the sufface of the wires, it's enameled wire. The wire sufrace is already protected. If you're worried about the surface of the enamel, are you going to be handling these with cotton gloves while you test them? As for the tangles, they're not causing any kinks/discontinuities. They don't get so tangled that the wires are bent to any degree. Not even as much as braiding or twisting. I make sure of that by addressing the tangles every few braids. It's a pain in the *** issue rather than a kinking/discontinuity issue.

Don't forget that here we are trying to credibly establish audible directionality in inter-connects/wire so I feel that simple twisted pairs might be better for unbalanced interconnects - braided cables may help to mask the effect and then again braiding may emphasise the effect - dunno yet.

Frank has mentioned testing single strands, and I have encountered strong differences here also.

How 'bout I just make up a braided set and a twisted set for the initial evaluation phase, where the directions are known?

Frank and I are mature enough and honest enough to listen only and not bother to closely visually inspect the test wires or cables.

I addressed this before. It's not about our trusting you and Frank not to peek. It's about the overall credibility of the test. That you simply COULD be able to determine direction by way of visual inspection would only undermine any positive result and could always be pointed to as a valid criticism and a source of ambiguity.

A cup hook screwed into a far wall, a battery drill and an assistant is all that is required to make consistently twisted pair cables - ask for more details if you like.

Again, this is enameled wire with a thin film insluation, not a thick, extruded thermoplastic. And while the enamel is a lot tougher than one would think, it's not nearly as robust as thick extruded thermoplastics.

Multiple sets of cable configurations (braided, twisted pair and single strand) ought to reinforce statistically positive findings.

How 'bout I just send you a set of each for the initial listening and you can report back which results in the more pronounced difference? Then we'll run the actual test with whatever that ends up being. If it's twisted, I'm willing to spend the extra time to try and keep the twists as consistent as possible.

se

Hi,

Sure, that's the point.

Unless the manufacturer actually on a marker on the wire, I wouldn't know which way is which of a piece of magnet wire.

I can't recall ever having seen enamel wire with markers on it but YMMV.

Anyways, let's move on with it...

Cheers,😉

I addressed this before. It's not about our trusting you and Frank not to peek. It's about the overall credibility of the test.

Sure, that's the point.

That you simply COULD be able to determine direction by way of visual inspection would only undermine any positive result and could always be pointed to as a valid criticism and a source of ambiguity.

Unless the manufacturer actually on a marker on the wire, I wouldn't know which way is which of a piece of magnet wire.

I can't recall ever having seen enamel wire with markers on it but YMMV.

Anyways, let's move on with it...

Cheers,😉

Re: Thread Jumping.............

Eric,

I could certain try to do that (no promises that I will meet your expectations). What aspects are you most interested in?

I have no problems, but am not sure that extra handling of the test cables would be generally accepted. Also, not sure that we should add more to Steve's efforts.

Thought about doing that, but I am just making a small point about using realistic cable inductance/reactace values (0.0000000... just wasn't working for me). I'll save starting a new thread for something more interesting/controversal : ).

JF

mrfeedback said:Seeing as you have the appropriate gear, do you mind measuring some representative cables like standard fig 8 power cable and others.

Eric,

I could certain try to do that (no promises that I will meet your expectations). What aspects are you most interested in?

It might be instructional for us all if Steve were to send you a length of the braided interconnects that he is making, and if I can talk him into twisted pair, these too.

I have no problems, but am not sure that extra handling of the test cables would be generally accepted. Also, not sure that we should add more to Steve's efforts.

It might be wise to shift this stuff to a new thread say 'Real Cable Measurements' or something.....

Thought about doing that, but I am just making a small point about using realistic cable inductance/reactace values (0.0000000... just wasn't working for me). I'll save starting a new thread for something more interesting/controversal : ).

JF

Initial Testing......

"How 'bout I just send you a set of each for the initial listening and you can report back which results in the more pronounced difference? Then we'll run the actual test with whatever that ends up being. If it's twisted, I'm willing to spend the extra time to try and keep the twists as consistent as possible."

Yes, that sounds fine by me.

Eric.

"How 'bout I just send you a set of each for the initial listening and you can report back which results in the more pronounced difference? Then we'll run the actual test with whatever that ends up being. If it's twisted, I'm willing to spend the extra time to try and keep the twists as consistent as possible."

Yes, that sounds fine by me.

Eric.

Re: Initial Testing......

Ok. You need a full meter each or would half a meter do ya think?

se

mrfeedback said:Yes, that sounds fine by me.

Ok. You need a full meter each or would half a meter do ya think?

se

mrfeedback said:1 meter would be better.

I had a feeling you'd say that. 🙂

No rest for the wicked I suppose.

So, we gonna shoot for delivery after the holidays as Frank suggested?

se

Steve, an assistant, a battery drill, a hook screwed into a far wall and about 5 minutes is all you need to make a very long twisted pair that you can cut into 1m sections.

Why not just make these as preliminary test cables and we can try them, and when you are ready with the plaited ones we can try them also ?.

As I said much earlier I am willing to put in the time and effort at this end, but I also say that my attention span is waning with all the continued debate on this forum by you generally about psychological effects etc in the absence of test data.

Sooner is better,

Eric.

Why not just make these as preliminary test cables and we can try them, and when you are ready with the plaited ones we can try them also ?.

As I said much earlier I am willing to put in the time and effort at this end, but I also say that my attention span is waning with all the continued debate on this forum by you generally about psychological effects etc in the absence of test data.

Sooner is better,

Eric.

mrfeedback said:Steve, an assistant, a battery drill, a hook screwed into a far wall and about 5 minutes is all you need to make a very long twisted pair that you can cut into 1m sections.

Do I need to remind you again that this wire hasn't the advantage of a thick, extruded thermoplastic insulation? I really don't wish to end up with a very long shorted pair.

If you want a twisted pair I'll build you a twisted pair.

Why not just make these as preliminary test cables and we can try them, and when you are ready with the plaited ones we can try them also ?.

Sure.

What was I supposed to supply initially? Three lengths?

As I said much earlier I am willing to put in the time and effort at this end, but I also say that my attention span is waning with all the continued debate on this forum by you generally about psychological effects etc in the absence of test data.

Why? It still holds true whether this test comes out positive or negative. Why does this fact bother you so?

Sooner is better

Sure.

se

No Facts = Conjecture = BS !!

Originally posted by Steve Eddy

Do I need to remind you again that this wire hasn't the advantage of a thick, extruded thermoplastic insulation? I really don't wish to end up with a very long shorted pair.

If the enamel is tough enough to wind transformers (or braided cables)it will be plenty tough enough to make twisted pairs from.

If you want a twisted pair I'll build you a twisted pair.

I think that they will work fine for the experiment, and easier to make and half the materials cost.

What was I supposed to supply initially? Three lengths?

For twisted pair say five channel lengths would be fine.

Why? It still holds true whether this test comes out positive or negative. Why does this fact bother you so?

"in the absence of test data" is why.

I can tell you how to make good twisted pairs reliably and easily if you ask.

Eric.

Originally posted by Steve Eddy

Do I need to remind you again that this wire hasn't the advantage of a thick, extruded thermoplastic insulation? I really don't wish to end up with a very long shorted pair.

If the enamel is tough enough to wind transformers (or braided cables)it will be plenty tough enough to make twisted pairs from.

If you want a twisted pair I'll build you a twisted pair.

I think that they will work fine for the experiment, and easier to make and half the materials cost.

What was I supposed to supply initially? Three lengths?

For twisted pair say five channel lengths would be fine.

Why? It still holds true whether this test comes out positive or negative. Why does this fact bother you so?

"in the absence of test data" is why.

I can tell you how to make good twisted pairs reliably and easily if you ask.

Eric.

Re: No Facts = Conjecture = BS !!

So? The statement isn't being applied solely to this one issue. It's axiomatic.

That you keep saying "if you ask" is why I haven't asked.

se

mrfeedback said:Originally posted by Steve Eddy

Why? It still holds true whether this test comes out positive or negative. Why does this fact bother you so?

"in the absence of test data" is why.

So? The statement isn't being applied solely to this one issue. It's axiomatic.

I can tell you how to make good twisted pairs reliably and easily if you ask.

That you keep saying "if you ask" is why I haven't asked.

se

- Status

- Not open for further replies.

- Home

- General Interest

- Everything Else

- Cable Directionality (Moved Threadjacking)