Hi guys,

There is one product called cable cooker from audiodharma. It is use for burning all your cables; interconnect, speaker cables or even powercord.

Does anyone know how to build a simple cable cooker, which can be used for speaker cables and power cord too?

thanks for any info

There is one product called cable cooker from audiodharma. It is use for burning all your cables; interconnect, speaker cables or even powercord.

Does anyone know how to build a simple cable cooker, which can be used for speaker cables and power cord too?

thanks for any info

Last edited:

This is a contentious issue. If the replies are considered outside forum rules, this thread will be closed.

well from the spec

12V power supply and a 555 driving a chipamp. Yours possibly for what is in your scrap drawer.

The CABLE COOKER produces signal levels far higher than those seen in normal audio/video system use. The Cooker's sweeping square wave oscillator drives a high-efficiency "H" bridge MOSFET switching circuit. The output signal is a square wave from below 100Hz to above 16 kHz, plus harmonics. Output voltage is 12 volts rms. The measured current flowing through the interconnect is 120 milli-amperes.

12V power supply and a 555 driving a chipamp. Yours possibly for what is in your scrap drawer.

Or just a 12v power supply and a resistor on the other end of the cable to limit the current. If it really does change the sound of the cable (which is not something I claim I would ever notice even if true) then applying any power through the cable over time must make a difference? Some blind listening tests should sort it out....

I think you mean a 556 (dual timer oscillator chip in 14 pin package). One half generates the low frequency modulation signal, a triangle-like wave. The other half implements a voltage controlled oscillator. Voila, output square wave frequency-vs-time ramps up and ramps back down in triangle-like fashion.well from the spec

12V power supply and a 555 driving a chipamp. Yours possibly for what is in your scrap drawer.

Trying to be the least contentous I can: I invite the op to think hard about how a cable is constructed and how a wire is formed in order to get a rough idea the plausibility that a low level signal wire (that includes speaker wire in the grand scheme of things) would have any sort of change over time from signal-based conditioning, much less one that would be in the range of audible.

If it's a poorly constructed cable and somehow the constituents react with each other or atmospherics gases, then an electrical change is quite possible. Or mechanical damage.

If it's a poorly constructed cable and somehow the constituents react with each other or atmospherics gases, then an electrical change is quite possible. Or mechanical damage.

Mark: I wasn't thinking about auto sweep, just a knob to change it. If I were going to that level I'd have an old laptop running some function gen code. Also generally free. Everyone has an old lappy lying arond somewhere. Or old phone.

There actually are some things that can change from cable break in.

On line level interconnects just inserting and removing them from their jacks should wipe them clean. This is actually measurable as small as it is. Of course a contact cleaner such as Caig De-Oxit works very well doing this and measures well before and a bit after application.

Now on any cable one important issue is being sure the polymers in the insulation are free of excess moisture and the polymers properly cured. Excess moisture comes from storage and can be removed by placing in a box with a light bulb for a heat source, or even an oven at low temperature. This can take a few days and is rarely significant.

Now it is possible to have improperly cured polymers in the insulation, but it is in my experience extremely rare and indicates a manufacturers' problem.

Now if you want to break in the cables with an electrical excitation I would just suggest connecting them to an audio power amplifier set at high gain (volume), playing low dynamic range music and connecting the wires without connecting the loudspeakers.

So in my OPINION it is possible for folks to have noticed changes from cable break-in but the cables most likely had some issues to begin with.

So if you try this please keep some untreated reference cables to compare to the treated ones.

On line level interconnects just inserting and removing them from their jacks should wipe them clean. This is actually measurable as small as it is. Of course a contact cleaner such as Caig De-Oxit works very well doing this and measures well before and a bit after application.

Now on any cable one important issue is being sure the polymers in the insulation are free of excess moisture and the polymers properly cured. Excess moisture comes from storage and can be removed by placing in a box with a light bulb for a heat source, or even an oven at low temperature. This can take a few days and is rarely significant.

Now it is possible to have improperly cured polymers in the insulation, but it is in my experience extremely rare and indicates a manufacturers' problem.

Now if you want to break in the cables with an electrical excitation I would just suggest connecting them to an audio power amplifier set at high gain (volume), playing low dynamic range music and connecting the wires without connecting the loudspeakers.

So in my OPINION it is possible for folks to have noticed changes from cable break-in but the cables most likely had some issues to begin with.

So if you try this please keep some untreated reference cables to compare to the treated ones.

You could experiment with something like this.Does anyone know how to build a simple cable cooker, which can be used for speaker cables and power cord too?

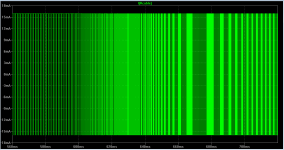

The first 555 timer/oscillator IC creates a slow ramp on node "CV2" which controls the oscillation of the second 555 IC. This is fed through a pair of CMOS inverters (CD4069, CD40106, whatever 15V CMOS inverter chips you have lying around) to an H-bridge. The H-bridge drives current through the cable in both directions; you can see that the current alternates between +16mA and -16mA.

Beware, this will drain a 9V battery pretty quickly: 600 mA-hr / 25mA = 24 hours. So you probably want to run it from a wall-wart or other AC-to-DC power supply.

_

Attachments

Improperly cured polymers? How does that work for a thermoplastic? And how does a square wave cure them?

Improperly cured polymers? How does that work for a thermoplastic? And how does a square wave cure them?

Duh, not all insulation is a thermoplastic! Among other insulations polyurethanes are used and heating will have an effect.

But thanks for trolling.

How does a square wave cure polyurethane?

BTW, most PUR wire insulation is thermoplastic PUR.

Heating from the square wave? Really?

BTW, most PUR wire insulation is thermoplastic PUR.

Heating from the square wave? Really?

How does a square wave cure polyurethane?

BTW, most PUR wire insulation is thermoplastic PUR.

Enough will heat it, who knows what less will do (that is sort of the open question) but the issue was that I have seen improperly cured polyurethane in real cables. The plant I visited used heat and a catalyst for the type they wanted. But go ahead change the subject.

Now Ed, we know you have seen more km of audio cable than we have had hot dinners in your time, but of that how much was improperly cured? And was that reels or assembled cables?

So you're saying that for PTFE, polypropylene, PVC, polyethylene, LSR, and TPU (99.99% of wire), there's no effect? And that for some unspecified thermoset PUR that you saw maybe once somewhere maybe possibly who knows as insulation, the heating from a small signal square wave is significant?

Just trying to clarify what you're claiming here.

Just trying to clarify what you're claiming here.

I think the point is uncured PU is going to need a lot more heat than the I^2*R that we'll get from electrically "cooking" the cable. Stick it in a low-temp oven, but below about 150C (SY can be more specific) if that's a concern.

If it's bad TPU, find a new manufacturer.

If it's bad TPU, find a new manufacturer.

I really think this sort of audiophoolery talk should be banned from Diyaudio. It's the only audio site on the Internet where actual knowledge and intelligent people can be found. Please let's keep this BS out of it. If we keep it flowing it will eventually take over, simply because stupidity is out there in greater numbers, and grows very quickly.

Last edited:

Now Ed, we know you have seen more km of audio cable than we have had hot dinners in your time, but of that how much was improperly cured? And was that reels or assembled cables?

About 5 reels of 2500'. If you actually read my post it mentioned that it could be a problem as I have encountered it. I did not say it was fixed by cable conditioning. This is the Troll King trying to slowly switch the issue from cable break in equipment issues and what break in can accomplish to a p'ing contest about various cable insulations.

The issue was how to try cable break in without spend a lot of money of a given device. I think the ever calm Mark J. has presented a fine circuit if one wishes to build one and my method was presented that requires no additional equipment.

Now if the OP does try it, I would be curious to see if he notes any changes. I do know I can measure the effects of De-oxit, clean connectors and even some differences between wire. My OPINION is that other than moisture contamination there should be no shift in measurable cable properties from low current break in.

Derfy,

The manufacturer ran a special replacement run and paid rush shipping to avoid warranty claims. installing suspect cable and later having it fail is VERY expensive. (But they do pay the claims!)

Last edited:

About 5 reels of 2500'. If you actually read my post it mentioned that it could be a problem as I have encountered it. I did not say it was fixed by cable conditioning.

I did read it, which was why I asked how often you have seen it. So basically one batch in a couple of decades? Albeit a big batch. Not bad QC on a big scale, although probably really pi55ed you off at the time?

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- Cable cooker