Hey everyone.

I'm slowly but surely getting into the hobby of making planar drivers. I've done research and I'm confident enough I can have a go at building my first driver. For the time being, I want to stick with building a planar headphone driver, Hifiman style. Having found teardown pictures online, their driver look sort of... amareutishly put together, even in their high end expensive pairs. Here's a picture of the Ananda's driver (500$)

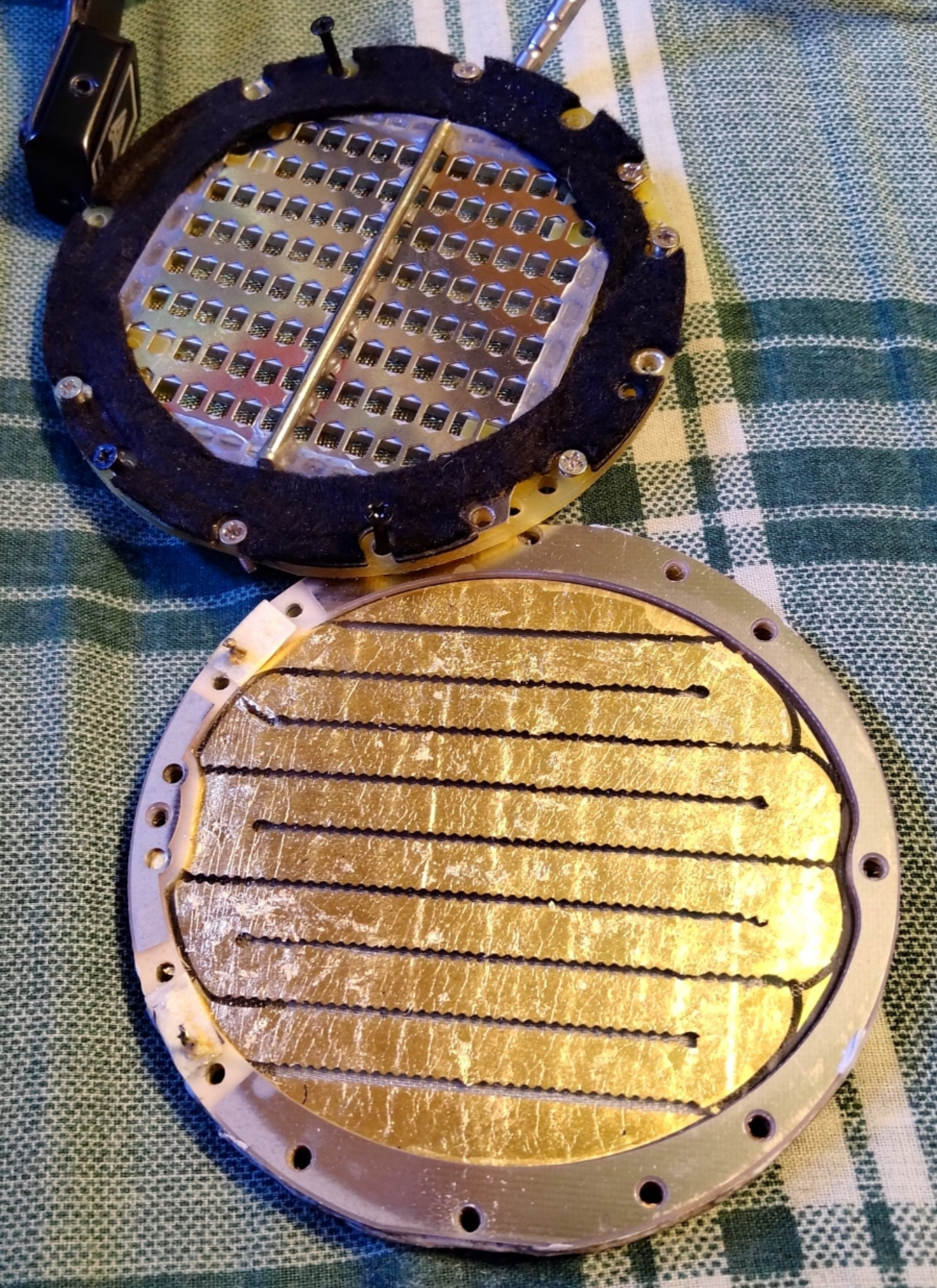

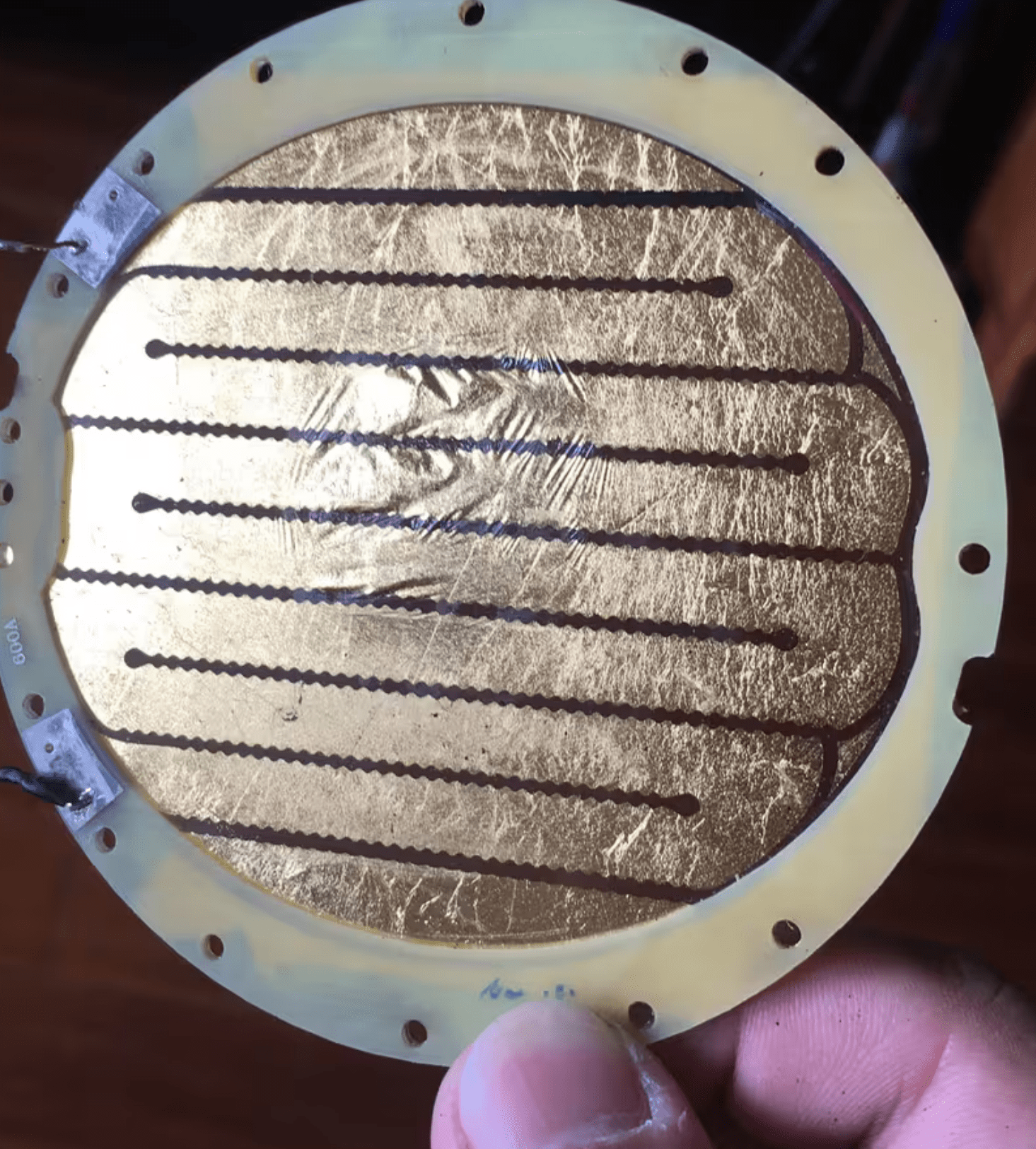

Or the HE-6 (1200$) which employs a thicker membrane that is gold-plated.

Or the HE1000SE (2250$), which uses rather thick traces.

I want to play around with thin, pre-aluminized Mylar preferably, to etch out the traces on the membrane using ferric chloride by masking them out with stencils.

My only issue is, I cannot seem to find any way to source the materials here in Europe.

Does anyone have any idea where I could get my hands on 1 to 10μm, preferably aluminized mylar, in reasonably small quantities?

Perhaps a fellow DIYer out there is sitting on a large stock and would be willing to part with a tiny bit of it, just so I can start playing around?

I'm slowly but surely getting into the hobby of making planar drivers. I've done research and I'm confident enough I can have a go at building my first driver. For the time being, I want to stick with building a planar headphone driver, Hifiman style. Having found teardown pictures online, their driver look sort of... amareutishly put together, even in their high end expensive pairs. Here's a picture of the Ananda's driver (500$)

Or the HE-6 (1200$) which employs a thicker membrane that is gold-plated.

Or the HE1000SE (2250$), which uses rather thick traces.

I want to play around with thin, pre-aluminized Mylar preferably, to etch out the traces on the membrane using ferric chloride by masking them out with stencils.

My only issue is, I cannot seem to find any way to source the materials here in Europe.

Does anyone have any idea where I could get my hands on 1 to 10μm, preferably aluminized mylar, in reasonably small quantities?

Perhaps a fellow DIYer out there is sitting on a large stock and would be willing to part with a tiny bit of it, just so I can start playing around?

Hey, I bought this aluminized kitchen foil in Belgium  unfortunately it is 15 um thick.

unfortunately it is 15 um thick.

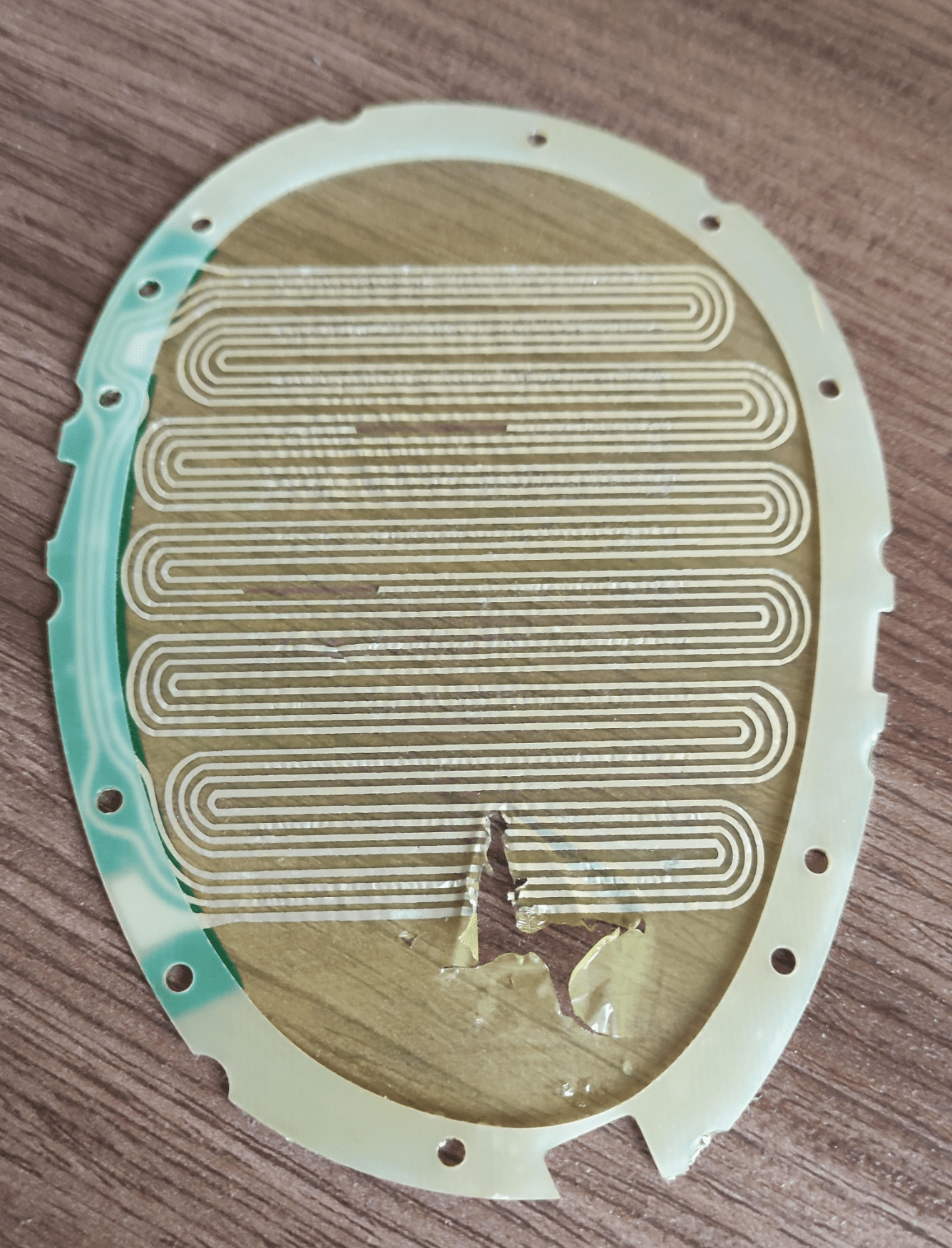

Etching is better with NaOH. I planned to use a photoresist, that is used by DIY printed circuit board making. A good film should be the first step, as on my photo.

I have a pair of perfectly working Technics EAH-820 headphones, and another pair with one side damaged. But never came to the point to finish it. Partly because I have a pair of Peerless PMB 100, also orthodynamic HP.

Etching is better with NaOH. I planned to use a photoresist, that is used by DIY printed circuit board making. A good film should be the first step, as on my photo.

I have a pair of perfectly working Technics EAH-820 headphones, and another pair with one side damaged. But never came to the point to finish it. Partly because I have a pair of Peerless PMB 100, also orthodynamic HP.

Attachments

That is extremely clean, wow! I'll go to Carrefour today and try and find the film that you used!

I have a few questions if you don't mind:

1) What kind of printer did you use to print the stencils you used to photo etch the traces? Toner printer? Inkjet? Specially ordered or just made at home with a competent printer on good transparent film?

2) I'm having a hard time wrapping my head around how to make a photoresisting etching on aluminized plastic foil. Do you spray the entire film with some sort of photosensitive product, lay the stencil on top, and expose it to UV light? It's hard finding informations online for this specific use case. But since you did exactly what I want to do, that's kinda perfect!

I have a few questions if you don't mind:

1) What kind of printer did you use to print the stencils you used to photo etch the traces? Toner printer? Inkjet? Specially ordered or just made at home with a competent printer on good transparent film?

2) I'm having a hard time wrapping my head around how to make a photoresisting etching on aluminized plastic foil. Do you spray the entire film with some sort of photosensitive product, lay the stencil on top, and expose it to UV light? It's hard finding informations online for this specific use case. But since you did exactly what I want to do, that's kinda perfect!

I have a scew caliper (micrometer) and measured the original diaphragm. The foil is 15 um, the aluminium traces are 20 um, total 35 um. When measuring, fold 4x, 8x, or even 16x, measure, then divide for better accuracy. The Carrefour foil is 15 um total.

I also have gold leaf, used by picture frame makers and art restaurators, but never tried to apply it to a plain mylar foil. Etching is with Aqua Regia, that is 75% HCl + 25% HNO3, at 90 °C. Or with so-called Lugol solution, that is I2 + KI + H2O 1:1:5, speed is 1 um/min. I is iodine, I think. Never tried it either, it comes from the literature.

I also have gold leaf, used by picture frame makers and art restaurators, but never tried to apply it to a plain mylar foil. Etching is with Aqua Regia, that is 75% HCl + 25% HNO3, at 90 °C. Or with so-called Lugol solution, that is I2 + KI + H2O 1:1:5, speed is 1 um/min. I is iodine, I think. Never tried it either, it comes from the literature.

Thanks a lot @lcsaszar, that really is helpful.

I've sent an email to Mike at FreeFlightSupplies because he's selling 5microns aluminized mylar foil rolls at a very attractive price. I will then use your technique to try and etch the trace on the foil. Thankfully, I have an very high resolution professional printer at home. I should be able to get some very good results. I have used it before to prepare screenprinting transparencies of very fine details with zero problems.

I've sent an email to Mike at FreeFlightSupplies because he's selling 5microns aluminized mylar foil rolls at a very attractive price. I will then use your technique to try and etch the trace on the foil. Thankfully, I have an very high resolution professional printer at home. I should be able to get some very good results. I have used it before to prepare screenprinting transparencies of very fine details with zero problems.

I don't know yet, I am at the very early stages of my research!

I've been mostly looking at other people's work, teardown of Hifiman's headphones, trying to find informations in forum threads...

If you have any good things to read on the subject, I'll take it, because it's mostly been reverse engineering at this point!

I've been mostly looking at other people's work, teardown of Hifiman's headphones, trying to find informations in forum threads...

If you have any good things to read on the subject, I'll take it, because it's mostly been reverse engineering at this point!

The commercial planar magnetic aka "orthodynamic" headphones that I have (Technics EAH-820 and Peerless PBM 100) both use ferrite magnets with holes on them. The magnets are on both sides of the diaphragm and have many smaller magnetic domains from the center to the edge like N-S-N-S-N.... according to the actual direction of the current in the diaphragm between them. The opposite magnets also repellant, because the magnetic field should be lateral. The Peerless is perhaps different, because the conductive layer is a continuous spiral from the center to the edge, the center is clamped and there is a fixed wire post attached to it.

There is a long thread on head-fi.org, titled "Orthodynamic roundup", with many good photos and other useful pieces of information.

There is a long thread on head-fi.org, titled "Orthodynamic roundup", with many good photos and other useful pieces of information.

https://www.head-fi.org/threads/technics-eah-830.197843/

Technics EAH-830, brother of EAH-820. Same construction with minor differences.

Technics EAH-830, brother of EAH-820. Same construction with minor differences.

That would be bad news! I'll guess I'll just try when I receive the two rolls I ended up ordering.

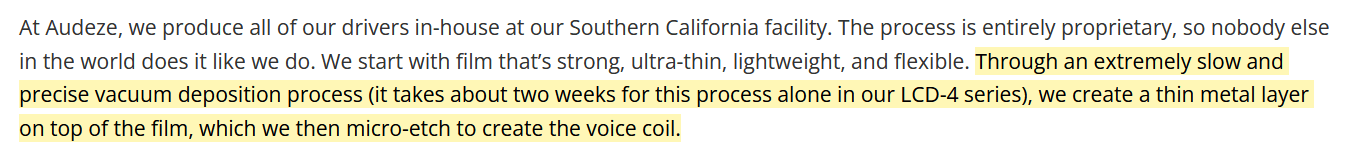

I know for a fact that Audeze uses vaccuum deposit to coat their drivers.

I also have found out that Hifiman, on its highest-end headphones (Susvara, 6K$), uses 'OS Film', that is 0.5 micron mylar and gold leaf.

If you look at the foil itself, you can kind of see that it's been brushed on and burnished by hand, not by a machine! I've done a fair amount of silver leaf gilding and this looks EXACTLY like it. I'm thinking they basically just gild the mylar and then etch it with chemicals.

So it makes me wonder whether 'amounts' are important here. A gold leaf is on average 0.15 microns. That would bring the entire thickness to 0.65microns, hence the insane resolution this pair of headphones have.

To further my point, I would argue that's it's precisely why the traces are so thick and cover the entirety of the membrane: to make up for the fact that the metal itself is extremely, extremely thin. It's a big trace so micro-cracks won't break continuity I would guess.

I know for a fact that Audeze uses vaccuum deposit to coat their drivers.

I also have found out that Hifiman, on its highest-end headphones (Susvara, 6K$), uses 'OS Film', that is 0.5 micron mylar and gold leaf.

If you look at the foil itself, you can kind of see that it's been brushed on and burnished by hand, not by a machine! I've done a fair amount of silver leaf gilding and this looks EXACTLY like it. I'm thinking they basically just gild the mylar and then etch it with chemicals.

So it makes me wonder whether 'amounts' are important here. A gold leaf is on average 0.15 microns. That would bring the entire thickness to 0.65microns, hence the insane resolution this pair of headphones have.

To further my point, I would argue that's it's precisely why the traces are so thick and cover the entirety of the membrane: to make up for the fact that the metal itself is extremely, extremely thin. It's a big trace so micro-cracks won't break continuity I would guess.

yeah thats an option of course, i would suggest fake silver leaf then.. since its alu and less heavy then copper. but yeah. that might be the only way of them getting 60Ohm + great for headphonesIf you look at the foil itself, you can kind of see that it's been brushed on and burnished by hand, not by a machine! I've done a fair amount of silver leaf gilding and this looks EXACTLY like it. I'm thinking they basically just gild the mylar and then etch it with chemicals.

So it makes me wonder whether 'amounts' are important here. A gold leaf is on average 0.15 microns. That would bring the entire thickness to 0.65microns, hence the insane resolution this pair of headphones have.

One thing I noticed when trying the photoresist UV sensitive spray on the Carrefour aluminized kitchen foil:

The photoresist spray does not cover it evenly. It gathers in drops on the surface. Probably the surface is covered by some hydrophob (oily) substance. A previous cleaning or pre-etching might be necessary, in order to make its surface matt, i.e. non glossy.

The photoresist spray does not cover it evenly. It gathers in drops on the surface. Probably the surface is covered by some hydrophob (oily) substance. A previous cleaning or pre-etching might be necessary, in order to make its surface matt, i.e. non glossy.

- Home

- Loudspeakers

- Planars & Exotics

- Buying thin (aluminized) Mylar in Europe?