Now here's where you really make me jealous. You have a tool shop and you know how to use it !

I have many years of experience with this type of work. It seems I was born with a hammer in my hand. 😉

The chassis is pretty near fully mocked up. Some details:

Whenever possible, I recycle and that is the case here. I bought the heatsinks (from barrredboss on Ebay) but that's pretty much it.

Here I'm using a piece of aluminum angle (cut from a mechanical door bottom seal that was surplus from a job I did) to join the 2 sections of heatsink together:

Yes, I could have used fewer screws but I like the way this looks. This is the top of the heatsinks, the bottom will be joined by the bottom panel of the chassis.

The bottom panel:

marked out and ready to cut. This is 16 gauge sheet metal (cut from a steel door) and is painted on one side.

Cut:

I use 'zipcut' blades in a mini-grinder to cut the metal. Hearing protection and eye protection (obviously) are needed. Cutting with these thin blades gives a near perfect cut, without distorting the metal from overheating or mechanical stress, like from shears. Start the cut nearest to you and go forward. This is safest and keeps the cut line visible.

To clean up the edge and deburr it, I use this type of sanding disk in the grinder:

it does an excellent job of smoothing the edge.

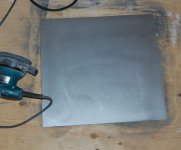

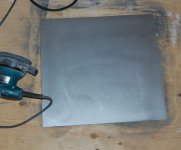

Cleaning the paint off the bottom panel was easy. Lacquer thinner (ventilation!) and a putty knife gets the majority off quite quickly. Sanding with a 320 grit disk in the random orbit sander finishes it:

Ready to use.

it does an excellent job of smoothing the edge.

Cleaning the paint off the bottom panel was easy. Lacquer thinner (ventilation!) and a putty knife gets the majority off quite quickly. Sanding with a 320 grit disk in the random orbit sander finishes it:

Ready to use.

Last edited:

The bottom is screwed to the heatsinks using sheet metal screws:

I'll be replacing these screws with #8 from McMaster Carr (when they get here). It's a good idea to mock up a chassis like this using smaller screws. This allows you to quickly get it done and the parts positioned correctly, while giving a margin of error. Also, taking it apart and putting it back together repeatedly can wear out the screw holes. Having them smaller to begin with will let you drill out a fresh, clean hole to the final size for the permanent screws.

A closeup of how it went together:

another angle joins the back to the bottom. Seen better here:

All I have left to do is to screw on the front panel (steel) and the rest is wood (actual front and top).

Getting all of the amp modules finished and fitted is next.

I'll be replacing these screws with #8 from McMaster Carr (when they get here). It's a good idea to mock up a chassis like this using smaller screws. This allows you to quickly get it done and the parts positioned correctly, while giving a margin of error. Also, taking it apart and putting it back together repeatedly can wear out the screw holes. Having them smaller to begin with will let you drill out a fresh, clean hole to the final size for the permanent screws.

A closeup of how it went together:

another angle joins the back to the bottom. Seen better here:

All I have left to do is to screw on the front panel (steel) and the rest is wood (actual front and top).

Getting all of the amp modules finished and fitted is next.

How ya gonna mount the trafo ? , It's heavy. It would bow the center of the genesis case if the piano hinges were removed. (1/8" AL) A little bracing ?

BTW , both primaries are faston ended - 12" long , secondary is 10" 3 wire 12ga. split at the last 2" to 2-14 ga. (6 fastons total secondary) over 20A.

OS

BTW , both primaries are faston ended - 12" long , secondary is 10" 3 wire 12ga. split at the last 2" to 2-14 ga. (6 fastons total secondary) over 20A.

OS

I will need to have it in hand and the other parts of the power supply before I can do anything else. I will create a steel cover for the transformer, and it may attach to the back, as well as the bottom. This would encompass the mains voltage part of the build, keeping it out of reach.

That would truely make it a monster !! Hope you have a sturdy shelf (You will most likely build one 😀 ) There was a issue of anything with steel leads picking up on the field of this toroid (if something was run close). The trafo itself never made a sound but anything steel near it was a issue. That was most likely why genesis buried it (and its brother -2 of them !) in a 1/8" potted sqaure 65lb box ! 😱 I like my tiny 500va Nikko trafo , all in a cute round steel container. I got sick of workouts in order to play with my amp. 🙁

OS

OS

I'll see how it fits. Most likely the cover (and transformer) would be better at the front of the chassis, attached to the steel front plate and steel bottom - there's more space there.

I just realized that I don't have enough 2SA1381/C3503 to make 6 of these modules. I really wish I had bought more of these when they were available from Digikey.

Mouser has the KSA/C versions but hfe 'D' for the NPN, 'E' for the PNP. Both of the ones I have are 'F'

It's getting more and more difficult to find decent TH devices. Soon they will have tube status.

I just realized that I don't have enough 2SA1381/C3503 to make 6 of these modules. I really wish I had bought more of these when they were available from Digikey.

Mouser has the KSA/C versions but hfe 'D' for the NPN, 'E' for the PNP. Both of the ones I have are 'F'

It's getting more and more difficult to find decent TH devices. Soon they will have tube status.

I'll be replacing these screws with #8 from McMaster Carr (when they get here).

On second thought:

Thank you for your order. Unfortunately, due to the ever increasing complexity of United States export regulations, McMaster-Carr will only process orders from a few long-established customers in Canada . We sincerely regret any inconvenience this causes you.

Thank you,

David Ulam

McMaster-Carr Supply Co

Nice.

Given the limited availability of the parts I originally selected, I've made a change. Considering that none of these parts used in the front end sees much dissipation, 7W devices are not needed. I'll swap the 2SA1381/C3503 for 2SC2631 and 2SA1123. These are 750mW and though they are TO-92, I can still clamp them to the heatsink.

These are a very capable replacement. I have 25 of each and will probably order some more while they are still around.

These are a very capable replacement. I have 25 of each and will probably order some more while they are still around.

On second thought:

Nice.

Frustrating.. aye 😕 ,perhaps this why the U.S. is going "under". I thought we had NAFTA or something, it is harder to ship something to Canada than it is to Germany (more paperwork !!)

Wish doing business w/ Canada was as easy as sneakin' over the Mexican border. 😀

OS

It is what it is, I guess. Disappointing, my order was nearly $200 - they have enough business already.

I have a supplier here, but I will have to go there (or call), make the order, wait for possibly a week, then go and pick it up. The kind of instant satisfaction I get from companies that want to do business (like Digikey) has me spoiled.

I felt like doing more this evening and rummaged through my wood pile where I found enough black walnut to make the face. The originals face is maple with walnut stripes. This one will be walnut with maple stripes:

glued up.

I have a supplier here, but I will have to go there (or call), make the order, wait for possibly a week, then go and pick it up. The kind of instant satisfaction I get from companies that want to do business (like Digikey) has me spoiled.

I felt like doing more this evening and rummaged through my wood pile where I found enough black walnut to make the face. The originals face is maple with walnut stripes. This one will be walnut with maple stripes:

glued up.

Better by far!

That puts the Genesis case I just sold to shame. And it did not cost $7000. BTW , looking at that case , you should have NO problem centering the 1KVA trafo and 100Kuf + of capacitance since your amps are mounted flat. 😎

OS

That puts the Genesis case I just sold to shame. And it did not cost $7000. BTW , looking at that case , you should have NO problem centering the 1KVA trafo and 100Kuf + of capacitance since your amps are mounted flat. 😎

OS

I knew you were about to please me !Front panel is fully machined:

Oh!.... God bless you because you are here sharing.... that you exist

You are a shinning star in this place dear transistor...i do think, believe and feel that you are precious...there are hundreds or fake DIY...you are a real one...you are on topic with the forum tittle.

Deep congratulations man....good......very good....more than good.... excellent!

regards,

Carlos

You are a shinning star in this place dear transistor...i do think, believe and feel that you are precious...there are hundreds or fake DIY...you are a real one...you are on topic with the forum tittle.

Deep congratulations man....good......very good....more than good.... excellent!

regards,

Carlos

Attachments

That puts the Genesis case I just sold to shame. And it did not cost $7000. BTW , looking at that case , you should have NO problem centering the 1KVA trafo and 100Kuf + of capacitance since your amps are mounted flat. 😎

OS

Thanks OS,

There will be a lot of support circuitry inside as well, so I thought it would be the best to mount the amp modules flat on the heatsinks. Less dramatic looking, but takes less space and has better heat transfer. I'd rather have more space than I actually need, rather than trying to pack everything in.

I'm thinking about changing the first one to mount the amps this way as well, freeing up some needed space in that chassis. Adding a solid bar of aluminum, 1.5" x 1/4" to the made-up heatsinks will give a smooth, consistent surface for mounting.

I knew you were about to please me !

Thanks Andrew. 🙂

You are a shinning star in this place dear transistor...i do think, believe and feel that you are precious...there are hundreds or fake DIY...you are a real one...you are on topic with the forum tittle.

Deep congratulations man....good......very good....more than good.... excellent!

Thank you very much Carlos. 🙂

I guess that the difference is that some of us do best in the physical world - building, creating, doing. While others do better in the academic world - reading, talking, more talking ( 😀 ). I enjoy both but really belong in the physical world.

Plan and talk forever more means nothing if you can't be bothered to build it.

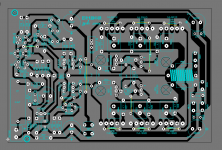

Board day 😉

I have further refined the board layout, changed the 2SA1381/C3503 to 2SA1123/C2631 and I'm ready to make 5 of these:

Should be fun. 🙂

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- ☠ Building a 6 channel amplifier

Several OT posts removed. Please stick to the subject.

Several OT posts removed. Please stick to the subject.