Would a brazilian ironwood make a good cabinet? It is a stupidly dense and strong wood, with 1220 kg/m³. The problem is, instead of a single piece for each side, I would have to glue smaller pieces, because the only pieces I can buy are not that wide.

Most people will tell you not to use solid wood, ever.

Wood Dimensional Changes

Even the most stable timber (teak) in a stable environment (São Paulo) is meant to have about 1% seasonal movement lengthwise, 2% across the grain.

However, in practice, some all-wood enclosures can be fine. I have used wood for three pairs of enclosures without problems.

1) bass boxes built with slabs & planks of hardwood, about 45mm thick. I kept these for ~15 years with no timber movement.

2) floorstanders built from 19mm floorboards. The boxes are a couple of years old, still stable.

3) a skin of thinner floorboards glued onto a 32mm thick ply box. There are still new, but seem fine so far.

Each time, I used old (recycled) local wood, and finished the cabs with oil. I don't see any movement in the timber - not even the 1 or 2 percent minimum that theory predicts. None. And I think I get a lot more humidity variation than you would in Brazil.

However, what has worked for me might not work for you. Maybe it only works with ye olde eucalyptus timber, milled >50 years ago - try it at your own risk with your local timber.

One risk-free possibility is: make a regular ply box, and add an ironwood face as a floating baffle (so that the front is a sandwich: ply, neoprene or similar, timber).

Use the same construction tricks that you see on solid timber tables (e.g. use bolts or pins set into slots to allow for movement).

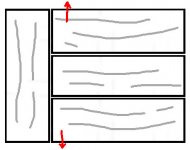

Note: most of the expansion is across the grain. So a baffle that was secured to the underlying box only along its midline, as pictured, would be free to expand / shrink across the width, so the pins would only have to allow for a trifling amount of vertical movement.

Wood Dimensional Changes

Wood is a hygroscopic material, i.e. it exchanges moisture with its surrounding environment. As a piece of wood loses moisture it shrinks and as wood gains moisture back it swells.

Even the most stable timber (teak) in a stable environment (São Paulo) is meant to have about 1% seasonal movement lengthwise, 2% across the grain.

However, in practice, some all-wood enclosures can be fine. I have used wood for three pairs of enclosures without problems.

1) bass boxes built with slabs & planks of hardwood, about 45mm thick. I kept these for ~15 years with no timber movement.

2) floorstanders built from 19mm floorboards. The boxes are a couple of years old, still stable.

3) a skin of thinner floorboards glued onto a 32mm thick ply box. There are still new, but seem fine so far.

Each time, I used old (recycled) local wood, and finished the cabs with oil. I don't see any movement in the timber - not even the 1 or 2 percent minimum that theory predicts. None. And I think I get a lot more humidity variation than you would in Brazil.

However, what has worked for me might not work for you. Maybe it only works with ye olde eucalyptus timber, milled >50 years ago - try it at your own risk with your local timber.

One risk-free possibility is: make a regular ply box, and add an ironwood face as a floating baffle (so that the front is a sandwich: ply, neoprene or similar, timber).

Use the same construction tricks that you see on solid timber tables (e.g. use bolts or pins set into slots to allow for movement).

Note: most of the expansion is across the grain. So a baffle that was secured to the underlying box only along its midline, as pictured, would be free to expand / shrink across the width, so the pins would only have to allow for a trifling amount of vertical movement.

Attachments

Well, my grandmother has some furniture made of brazilian rosewood and for 40 years it had no wood movement and everything is very nice and tight. Ironwood is 20% denser than rosewood.

Well, my grandmother has some furniture made of brazilian rosewood and for 40 years it had no wood movement and everything is very nice and tight. Ironwood is 20% denser than rosewood.

Grand, sounds good.

What sort of furniture? In something like a Quaker chair, the joints would simply rotate slightly to compensate for swelling, so that wouldn't really tell you how the timber would perform in a solid box shape.

The real test is: are there any long joins where the grain directions are perpendicular, like in my image? That is what (might) kill the joins in a speaker. In theory, a rise in humidity would swell the 3 horizontal pieces twice as much as the vertical piece, in the direction of the red arrows.

If your grandmother's furniture has such joints, and they have survived 40 years, you should be good to go.

Note: some people might object on the basis that solid wood is more resonant than ply / MDF / granite / mithril. This might be true, but I think that, if comparing two equivalently well braced and heavily built boxes, the differences would be slight.

Attachments

Solid can be used for building speaker boxes. You do need to know what you are doing.

Bernie often builds solid wood enclosures. Here his latest. Mar-Ken12pwxwT Standmounts.

You can see the regular Mar-Ken12wpwxT in the background which Bernie executed in solid maple.

dave

Bernie often builds solid wood enclosures. Here his latest. Mar-Ken12pwxwT Standmounts.

You can see the regular Mar-Ken12wpwxT in the background which Bernie executed in solid maple.

dave

Grand, sounds good.

What sort of furniture? In something like a Quaker chair, the joints would simply rotate slightly to compensate for swelling, so that wouldn't really tell you how the timber would perform in a solid box shape.

The real test is: are there any long joins where the grain directions are perpendicular, like in my image? That is what (might) kill the joins in a speaker. In theory, a rise in humidity would swell the 3 horizontal pieces twice as much as the vertical piece, in the direction of the red arrows.

If your grandmother's furniture has such joints, and they have survived 40 years, you should be good to go.

Note: some people might object on the basis that solid wood is more resonant than ply / MDF / granite / mithril. This might be true, but I think that, if comparing two equivalently well braced and heavily built boxes, the differences would be slight.

There are joints like that in the corners of doors, and they open and close very well and everything is nice and tight.

Solid can be used for building speaker boxes. You do need to know what you are doing.

Bernie often builds solid wood enclosures. Here his latest. Mar-Ken12pwxwT Standmounts.

You can see the regular Mar-Ken12wpwxT in the background which Bernie executed in solid maple.

dave

These speakers look really good. I don't think there are issues with ressonance in subwoofers. When I knock on most wood they don't sound like subwoofer frequencies.

An externally hosted image should be here but it was not working when we last tested it.

This is the solid wood I can buy.

An externally hosted image should be here but it was not working when we last tested it.

And those are the veneers.

This store sells both, and as you can see, ironwood is not a very wide tree, only 40 - 60 cm wide, and I don't want the softer auburn in my subwoofers. What is the best way to glue this kind of very hard wood? Epoxy, standard PVA or polyurethane glue?

Gluing up several boards to make one large piece adds inherent stability and if you are not listening at concert levels, cabinet resonance will not be an issue. That dense of wood simply can not be activated by the drivers we use in our homes.

Gluing up several boards to make one large piece

Seen in every solid wood build (quite a few) i have seen from Bernie or Scott.

dave

woodworking (floors) for over 30 years WOOD MOVES ! Its a HYGROSCOPIC !https://en.wikipedia.org/wiki/Hygroscopy

Unless you use Quartersawn which in some wood produces wonderful Medullary rays(Tiger striping) its gonna move. That wonderful flat grain that give the dark soft grain vrs rosy hard grain is not as stable as wood moves across the grain. Quartred is strait up and down and has very little movement. Glued and biscuit joined with smaller pieces ,Id opt for MDF and veneer as you can get the best of both worlds. stability and looks !

Unless you use Quartersawn which in some wood produces wonderful Medullary rays(Tiger striping) its gonna move. That wonderful flat grain that give the dark soft grain vrs rosy hard grain is not as stable as wood moves across the grain. Quartred is strait up and down and has very little movement. Glued and biscuit joined with smaller pieces ,Id opt for MDF and veneer as you can get the best of both worlds. stability and looks !

What about sealing the wood with a thick coat of PU Varnish? Wouldn't that seal the wood and prevent wood movement? My grandmother has some mdf speakers as well, and they got bloated and delaminated, while her rosewood furniture remained all nice and tight. Well, her speakers have 20 years while her furniture has 40. My experience shows that rosewood and ironwood are better than MDF. Everything made of MDF has a tendency to bloat and delaminate where I live. A friend of mine has a B&W center channel that bloated and delaminated pretty damn quickly, within like 5 years.

Birch multi layer ply covered in the iron wood veneer.. Bloating is caused by Hygroscopic environment..

I have been making speaker cabinets from solid wood for a long time. Only once have I had an issue with shrinkage. I used a dado joint in a front panel brace. The brace was plywood the front panel was edge grain Douglas fir. The speaker was quite close to my heater in the living room. A crack developed during the winter.

I think solid wood offers opportunities that veneered plywood does not.

I do not recommend the use of MDF for speaker cabinets.

Wood that has been properly kiln dried is quite stable. If you look at the wooden furniture in your house, you will find that the wood was likely cut into strips and glued back together.

I hope this helps

I think solid wood offers opportunities that veneered plywood does not.

I do not recommend the use of MDF for speaker cabinets.

Wood that has been properly kiln dried is quite stable. If you look at the wooden furniture in your house, you will find that the wood was likely cut into strips and glued back together.

I hope this helps

Cost is the number 1 reason manufactures dont use solid is #2 Is Solid wood is to unpredictable. They are not gonna chance it on environment. MDF is outstanding sub bass for veneer and is very good acoustically. Multi layered birch is also great but twice the cost.. Fir is NOT a hard wood and is much more stable.. It swells at a cellular level and one stable never moves again. WHY DO WE USE IT FOR SUB FOUNDATIONS WORK...

Gluing small strips is what I suggested and going with Quartered wood.

Would I use solid wood of any sorts for the box NOPE.. But one can do what one wants..

Gluing small strips is what I suggested and going with Quartered wood.

Would I use solid wood of any sorts for the box NOPE.. But one can do what one wants..

Thanx Scott (SCD is the Scott i refered to earlier)

MDF is a poor material for building speakers.

dave

Id opt for MDF

MDF is a poor material for building speakers.

dave

Cost is the number 1 reason manufactures dont use solid is #2 Is Solid wood is to unpredictable. They are not gonna chance it on environment. MDF is outstanding sub bass for veneer and is very good acoustically. Multi layered birch is also great but twice the cost.. Fir is NOT a hard wood and is much more stable.. It swells at a cellular level and one stable never moves again.

Cost is the reason speaker manufacturers use MDF. It is cheap. Cheap to buy, cheap to work, cheap to finish.

It is not very good acoustically. Good plywood is considerably better.

Of the solid wood boxes thru here and i hav epurposly tortured them, the only issue is the one Scott described. Douglas Fir (a pine), maple, walnut, yew, locust, various oaks, western red cedar (really quite good except for getting the outside more immune to dings). Bernie & Scott have also built speakers i haven’t seen, and them may encompass other woods. Bernie did take away some Arbutus logs for drying and milling.

Gluing small strips is what I suggested and going with Quartered wood.

I did say you had to know what you were doing and that is a given.

Lots of examples of solid wood builds in this thread: http://www.diyaudio.com/forums/planet-10-hifi/214897-minionken-fonken-gallery-pictures-only.html

dave

C.A.P. - perhaps you've never heard of Boenicke Audio?

- Boenicke Audio

Scott Dunn, and Bernie Foucher, - of whose stunning work only two examples are displayed in Dave's photo above - are two artisans with at least as much accumulated experience working with solid wood as your own, and other than the one failure that Scott mentioned above, I've yet to see any problems with the dozens of their builds with both soft and hardwoods. You should see Scott's house.

and yes, we've directly compared identical speaker enclosures built from MDF and Baltic Birch plywood - once, well over 10yrs ago. The best multi-ply I can obtain locally (let's call it Apple Ply for convenience) costs me well over 3 times what MDF does, and as far as I'm concerned is worth every penny.

- Boenicke Audio

Scott Dunn, and Bernie Foucher, - of whose stunning work only two examples are displayed in Dave's photo above - are two artisans with at least as much accumulated experience working with solid wood as your own, and other than the one failure that Scott mentioned above, I've yet to see any problems with the dozens of their builds with both soft and hardwoods. You should see Scott's house.

and yes, we've directly compared identical speaker enclosures built from MDF and Baltic Birch plywood - once, well over 10yrs ago. The best multi-ply I can obtain locally (let's call it Apple Ply for convenience) costs me well over 3 times what MDF does, and as far as I'm concerned is worth every penny.

Last edited:

Easy fellas. Lets not get our panties in a bunch now. AS a fellow WOOD worker who gets WHAT YOUR BOTH saying.. Most laymen do not know what a moisture meter is or how to add stability back into wood or how exotics are not always glue friendly ..

I offered help based on woods reaction to moisture. I am sure the poster does not have a CNC router or tools that are the likes of a master craftsman other wise he would not have asked the question..

Like I said DO WHAT ONE WANTS and believes will work and be best..

Ill stick to BOX LESS as I do not prefer the sound of ANY !

I offered help based on woods reaction to moisture. I am sure the poster does not have a CNC router or tools that are the likes of a master craftsman other wise he would not have asked the question..

Like I said DO WHAT ONE WANTS and believes will work and be best..

Ill stick to BOX LESS as I do not prefer the sound of ANY !

Wood moves with moisture content and ambient humidity level. A good rule of thumb for walnut over the course of an annual round of seasonal weather is to expect 1/8" (3mm) of max to min dimensional movement across an 8" (203mm) width. This can obviously be dealt with successfully as centuries of furniture makers have demonstrated. The most critical issue is managing wood movement at a joint where cross grain wood (that moves substantially) meets long grain wood (that moves very little).

In speaker building a cabinet can be made where the sides, top, and bottom are all joined at cross grain to cross grain joints. Since these will move together there will not be undue stresses developed but the speaker cabinet will increase in depth in humid seasons and decrease in depth in dry seasons. Now if you use a high quality plywood for the front and back, the plywood, which is stable will be joined to long grain wood which is also stable and you will have a speaker box that should hold up very well.

In speaker building a cabinet can be made where the sides, top, and bottom are all joined at cross grain to cross grain joints. Since these will move together there will not be undue stresses developed but the speaker cabinet will increase in depth in humid seasons and decrease in depth in dry seasons. Now if you use a high quality plywood for the front and back, the plywood, which is stable will be joined to long grain wood which is also stable and you will have a speaker box that should hold up very well.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Brazilian Ironwood Cabinet