Ok so i always see the bracing that goes from a panel to a front panel like inside a horn

does that needs to be like that ?

can you just brace like i saw on some 2000 era Yorkville's

LS608's to be exact

they use like a 1" by 2" wood sticks in the corners

like the below

does that augment the corner structural integrity if you drop it

or the roadies abuse the boxes ( like always )

and what about mid panel bracing like this that i found inside the yorkvilles

in L shape

can we get away with no L bracing like the below

and my question is.... do you really need to do the bracing like the below ?

or with the L braces along wide areas in the panel when flex occur you can be ok

also can you make it with single baffle wall or use double baffle wall

does that needs to be like that ?

can you just brace like i saw on some 2000 era Yorkville's

LS608's to be exact

they use like a 1" by 2" wood sticks in the corners

like the below

does that augment the corner structural integrity if you drop it

or the roadies abuse the boxes ( like always )

and what about mid panel bracing like this that i found inside the yorkvilles

in L shape

can we get away with no L bracing like the below

and my question is.... do you really need to do the bracing like the below ?

or with the L braces along wide areas in the panel when flex occur you can be ok

also can you make it with single baffle wall or use double baffle wall

Last edited:

The point is to put bracing in the middle of each panel, to reduce the span of unbraced panel size, and thus increase the vibration resonant mode for that panel segment. You want that mode above the operating frequencies of the subwoofer.

Just bracing the edges makes the subwoofer more robust and less prone to falling apart when tossed about by roadies, but does not address the panel resonance freq. Think of each panel as something like a very stiff passive radiator.

Just bracing the edges makes the subwoofer more robust and less prone to falling apart when tossed about by roadies, but does not address the panel resonance freq. Think of each panel as something like a very stiff passive radiator.

The corner pieces help make the joint, especially if the fit is not great without them. It gives somewhere to use screws since it's not always good screwing into the end of a panel, and it increases the glue surface. However wood glue is quite strong when used properly.

The box is fundamentally stronger in the corner so that's not where you get the most benefit. As you've surmised, it makes most sense where there is more movement.

The box is fundamentally stronger in the corner so that's not where you get the most benefit. As you've surmised, it makes most sense where there is more movement.

When the panel bends, the parts of the brace that are further from the panel will tend to stretch and compress more. This makes them more effective. You can do the same thing with any rectangular cross section brace that is placed directly on a single panel, by mounting it on it's narrow edge.

The greater factor would be the thickness at the outer edge, so for a given overall cross section, the rectangular.

There are many factors that add secondary concerns that could come into play.

There are many factors that add secondary concerns that could come into play.

Yes, a brace from one panel to it's opposite prevents the panels operating in phase with respect to the outside of the cabinet.

so like this

It's all about stiffness.

The precise answers will requires Finite Element Analysis (FEA) simulation.

If you want to learn more about you can look in the internet about "Beam Stiffness and Bending" so you can learn the basics.

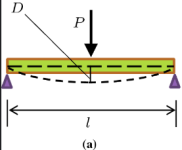

For instance, see attached picture, if a beam has two supporting points, the maximum bending will be in the middle.

So if you have a panel, the maximum flexibility will be in the middle of the panel, and that is the place you need more reinforcements. When one panel is already joined to a side panel, the stiffness is already high close to the joint, so adding reinforcements there is not so wise, you are loosing material and internal volume at the end, maybe compromising the low frequencies.

You can also take some inspiration looking to plastic components and check their ribs placements and form or also buildings in your city.

Attachments

no wonder most of the TH designs have that kind of bracing where one panel reach the opposite panel and then they cut holes to make em lighter ?Yes, a brace from one panel to it's opposite prevents the panels operating in phase with respect to the outside of the cabinet.

so the below bracing will not suffice??

do i need to brace this panel ?

do i need to double baffle ?

3/4" times 2 will be a 1 1/2" baffle

do i need to brace this panel ?

Yes you need. When possible use a common brace to reinforce two panels or more, in this place you can reinforce the back panel too.

The type and amount of brace will depend of the plywood thickness you are using and the driver power handling.

When you make holes in the brace is the reduce volume/weight without sacrificing stiffness.

Your braces attached along the single panels do have an effect, and even a single brace attached between the other braces across the middle of the cabinet will help. This is the point of most movement and it also manages the box zeroth mode. It helps to consider which modes are more important to manage

I do use corner cleats but mostly rely on P2P bracing to the side panels. These are not placed in the centre of the panel to divide into equal sections where resonances would be similar so usually placed 0.6x so resonances would differ. I also add driver cutouts to increase the panel stiffness at the P2P location. Disregard the 45° pieces in the corners as this enclosure had large vertical 45° bevel sections from the side to baffle.

Attachments

What you mean by that ?I also add driver cutouts to increase the panel stiffness at the P2P location.

- Home

- Loudspeakers

- Subwoofers

- bracing revisited