With all due respect, this is completely incorrect. There is a reason why subwoofer cabinets which operate solely below 100Hz are designed to be as stiff and as massive as possible, even though their individual panel resonances occur above the passband. It is the driver motion itself causing excitations in the enclosure that said bracing eliminates.

Schwingungen an Lautsprechergehusen

If you scroll that page downwards, you will see, that we do not disagree in this field.

But in this thread some tried to explain rather wide banded loss in lower bass between say 50Hz and 70Hz by cabinet vibration.

The small (this is a keyword !) subwoofers i show on my website are made of 19mm MDF and since the shape and size is optimized due to stiffness the first resonance occurs at approx. 220Hz.

That shape, size and material is surely not too far from that "mission 752" cabinet mentioned in this thread except for the 752 being more stretched into height (one dimension).

Let there be resonances from say 80Hz on in case of the "752" (unlikely though), but you cannot explain loss in lower bass by cabinet vibration in this case:

Very very unlikely, and i know pretty well, what i am talking about, since i do those resonance measurements on a routine base with all of my cabinets.

BR-alignment has to be analysed here, especially any changes in fb and Qb.

Last edited:

Hello again,

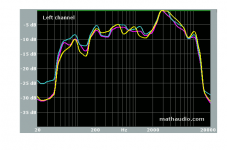

Well I've now listened to the setup with the one baffle brace just under the tweeter and it's sounding pretty good to me. Bass is back in acceptable quantities but well controlled - I know the kind of bass 'boom' that you're refering to, lemans 23, and I don't like it, hence the bracing... I've done the measurements, graph posted below. As always unmodded in yellow, pre-bracing in blue, current setup in pink. After Christmas I may experiment with a second baffle brace much lower down, hitting the back panel just above the cutout for the speaker connections/crossover and well away from the reflex ports. This should not only reduce baffle vibrations but also crossover microphony, could be win win if it works.

Chris661 - I'm well aware of the peak you've pointed out - I hope that when I do the tweeter mods I've got planned this will be reduced/eliminated. People have often said the original 752's and 753's with the metal tweeter are too bright but before I made myself some decent low capacitance interconnects I didn't mind the balance. Now I can hear it more clearly it's on my list of things to be got rid of.

I'll keep you posted with future developments, in the meantime thanks for all the input and have a great Christmas

Mark.

Well I've now listened to the setup with the one baffle brace just under the tweeter and it's sounding pretty good to me. Bass is back in acceptable quantities but well controlled - I know the kind of bass 'boom' that you're refering to, lemans 23, and I don't like it, hence the bracing... I've done the measurements, graph posted below. As always unmodded in yellow, pre-bracing in blue, current setup in pink. After Christmas I may experiment with a second baffle brace much lower down, hitting the back panel just above the cutout for the speaker connections/crossover and well away from the reflex ports. This should not only reduce baffle vibrations but also crossover microphony, could be win win if it works.

Chris661 - I'm well aware of the peak you've pointed out - I hope that when I do the tweeter mods I've got planned this will be reduced/eliminated. People have often said the original 752's and 753's with the metal tweeter are too bright but before I made myself some decent low capacitance interconnects I didn't mind the balance. Now I can hear it more clearly it's on my list of things to be got rid of.

I'll keep you posted with future developments, in the meantime thanks for all the input and have a great Christmas

Mark.

Attachments

I normally cld brace drivers to the corners eg side wall back wall junction. Not the true corners. This reduces the distortion while not inducing torsion related coupling. Enclosure walls are cld braced amoungst each other.

...do you you have an instructive example as a picture ?

Cheers

Interesting conjecture. Sadly does not hold water, for example a mltl I designed has little resonance issues below 140hz. It's nothing more than a sonotube, cardboard 1/8" thick with a 3/4" mdf lengthwise divider and endcaps. At 200 and up it certainly does but is not operated that high, it's a sub.With all due respect, this is completely incorrect. There is a reason why subwoofer cabinets which operate solely below 100Hz are designed to be as stiff and as massive as possible, even though their individual panel resonances occur above the passband. It is the driver motion itself causing excitations in the enclosure that said bracing eliminates.

Oliver, sadly no longer. Once upon a lifetime ago had notebooks full of scribbles. What remains is in my head but this is based on decades of reading, experimentation and testing. If my current project's wheels ever hit the ground again I will certainly post pics.

I may draft up a few drawings for clarity, old school on paper. 😉 Sounds simple but implementation can be a pita. For example Dr Geddes does not use screws as they reduce isolation cld benefits. In some ways I feel he is correct, but only because there may be a better way to join two panels. Sometimes screws are manditory like with cross bracing but even those can be isolated, just adds several additional steps that few are willing to do.

Feel that if a panel is going to reradiate then I choose the panel to do so uniformly eg minimal hotspots. Joints between adjoining panels must be allowed to flex in and out while minimizing bending torsion that normal box construction maximally induce into adjoining panels adding coloration through mechanical stresses. Isolating these bending moments greatly reduces the hotspots and seperately dampens the panel as a whole when fully built out box in a box cld.

FYI in my little bubble of audio (isolation), have found it prudent to schlok off the marketing speak and find out firsthand what is and what is not. Measurements matter. Found I tend to agree with Harbeth, Geddes, Olson, Smith ,etc. I've been a big proponent of CLD since the early '80's when I discovered landing gear on small aircraft use it to compensate for the springiness (ringing).

I may draft up a few drawings for clarity, old school on paper. 😉 Sounds simple but implementation can be a pita. For example Dr Geddes does not use screws as they reduce isolation cld benefits. In some ways I feel he is correct, but only because there may be a better way to join two panels. Sometimes screws are manditory like with cross bracing but even those can be isolated, just adds several additional steps that few are willing to do.

Feel that if a panel is going to reradiate then I choose the panel to do so uniformly eg minimal hotspots. Joints between adjoining panels must be allowed to flex in and out while minimizing bending torsion that normal box construction maximally induce into adjoining panels adding coloration through mechanical stresses. Isolating these bending moments greatly reduces the hotspots and seperately dampens the panel as a whole when fully built out box in a box cld.

FYI in my little bubble of audio (isolation), have found it prudent to schlok off the marketing speak and find out firsthand what is and what is not. Measurements matter. Found I tend to agree with Harbeth, Geddes, Olson, Smith ,etc. I've been a big proponent of CLD since the early '80's when I discovered landing gear on small aircraft use it to compensate for the springiness (ringing).

...do you you have an instructive example as a picture ?

The bracing method in this patent might be what is being referred to by Greebster.

I had this same idea a while ago but when I searched I found I wasn't the first to think of it. I haven't tried it yet to see how effective it is.

Greebster said:Feel that if a panel is going to reradiate then I choose the panel to do so uniformly eg minimal hotspots. Joints between adjoining panels must be allowed to flex in and out while minimizing bending torsion that normal box construction maximally induce into adjoining panels adding coloration through mechanical stresses. Isolating these bending moments greatly reduces the hotspots and seperately dampens the panel as a whole when fully built out box in a box cld.

Hi Greebster,

yes i had built such a cabinet using viscoelastic joints too but also with lining on the walls and "dampening braces" similar to that patent mentioned above.

Minimising bending moments is a valid strategy IMO and i agree too, that extreme stiffness at adjoining corners e.g. may be counterproductive in a "wideband enclosure" (as i said, subwoofers are a different "kind of sports").

To reduce structure born sound from a cabinet or machine housing one keyword in german is "Fugendä(ae)mpfung". I am currently not able to translate exactly, but could be like "dampening joint" or "gap dampening".

It is simply preventing (the bending wave's) vibrational energy going from one part of the strucure to another by "decoupling". This means making up a mechanical lowpass filter usually ...

Decoupling is a common way in engineering to solve vibrational problems in any kind of structure, being it a bridge over a valley the body of an aircraft.

Would be kind of strange if not applicable to speaker cabinets either ...

Cheers and

Merry Christmas

Oliver

Last edited:

Happy New Year everyone!

I've done some more work on the speakers so I thought I'd post an update. I've now added a second front to back brace lower down in the cabinet that hits the back wall just above the cutout for the terminal connections/crossover. I've also done some mods on the tweeters, replacing the foam plug in the back chamber with long fibre wool and adding a ring of felt on top of the pole piece, as per this link:

Tweaks for Tweeters

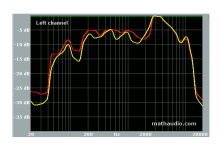

The treble now sounds smoother and less metalic, but as you can see from the graph below there's no real change in the peak centred around 3600Hz. As far as I know this is the crossover frequency, so I'll have to think about altering the crossover components to correct this.

That's it for mechanical mods to the speakers, thanks for all the info on cld bracing - definitely something I'll keep in mind for a future speaker build but not worth it for these old 752's! Frequency response below, original in yellow, current setup in red. I'm happy with the sound, bass is much more accurate with the stiffer cabinet and fewer internal reflections, timing and imaging have improved a lot. I'll probably start a new thread about the crossover once I've had a look at the current circuit.

I've done some more work on the speakers so I thought I'd post an update. I've now added a second front to back brace lower down in the cabinet that hits the back wall just above the cutout for the terminal connections/crossover. I've also done some mods on the tweeters, replacing the foam plug in the back chamber with long fibre wool and adding a ring of felt on top of the pole piece, as per this link:

Tweaks for Tweeters

The treble now sounds smoother and less metalic, but as you can see from the graph below there's no real change in the peak centred around 3600Hz. As far as I know this is the crossover frequency, so I'll have to think about altering the crossover components to correct this.

That's it for mechanical mods to the speakers, thanks for all the info on cld bracing - definitely something I'll keep in mind for a future speaker build but not worth it for these old 752's! Frequency response below, original in yellow, current setup in red. I'm happy with the sound, bass is much more accurate with the stiffer cabinet and fewer internal reflections, timing and imaging have improved a lot. I'll probably start a new thread about the crossover once I've had a look at the current circuit.

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Bracing cabinet lost the bass