Suppose we're gunna build our latest shake-the-neighbourhood sub and we don't really like the idea of the enclosure flexing in and out like some kind box-shaped lung. We have to brace the panels to make them nice and rigid. Now, my question is this: pine is quite cheap and you can get it just anywhere but seeing it is a softwood, what is its strength like? There are various kinds of hardwood available - at a price - so what is the strength and rigidity of these like compared with softwoods like pine?

Also, what about steel? I could well imagine a piece of 30x30mm angle or U shape or even box section especially would be very rigid. Actually, one shape I had been thinking about most of all is a T shaped cross section. It can take screws down each side and the centre bit can take a strut from it to the opposite side brace. Only thing is, you cannot glue steel to the panel; maybe some RTV silicone rubber might be ok along with lots of screws.

What's your experience with braces?

Also, what about steel? I could well imagine a piece of 30x30mm angle or U shape or even box section especially would be very rigid. Actually, one shape I had been thinking about most of all is a T shaped cross section. It can take screws down each side and the centre bit can take a strut from it to the opposite side brace. Only thing is, you cannot glue steel to the panel; maybe some RTV silicone rubber might be ok along with lots of screws.

What's your experience with braces?

dont use pine in speakers! it expands and contracts like a russian U-boat, use MDF its plenty stong enough and it wont expand/contract

Using MDF for panels of course, but I didn't think it would be strong enough for a brace when you have to put a screw into it's edge.

MDF should be alright but I wouldn't suggest using screws to hold the bracing in place. I personally use little cookies that fit in a slot made in both pieces of wood. You need the proper tool though to make the slots.

http://www.lamello.com/english/hv_sys_e.htm

Coupled with good carpenting glue, this system is flex proof and does a really good job. You will also need several clamps to make that there is enough pressure on the joint to seal the whole enclosure.

Hope this helps!

Sébastien

http://www.lamello.com/english/hv_sys_e.htm

Coupled with good carpenting glue, this system is flex proof and does a really good job. You will also need several clamps to make that there is enough pressure on the joint to seal the whole enclosure.

Hope this helps!

Sébastien

who says you need to screw it, the glue holds much stronger than the screws, if you arent using fitted joints then just use small screws to hold it while the glue dries, or even little nails, my subwoofer box i am currently building use no screws or nails, its all done to fit together and clamped while glue dries.

and MDF is plenty strong enough for bracing, if you are concerned just use alot of it 🙂

and MDF is plenty strong enough for bracing, if you are concerned just use alot of it 🙂

Try dried hardwood dowel 20-30mm diameter, cut and trimmed to length so that it just fits in and has to be almost jammed into place. The drill a pilot hole through the panel into the end of the dowel and screw up tight. I use epoxy to seal then. You can work out a pattern of the dowels so that they break up the panel modes, and use them between all 6 panels.

If you use some sort of damping material like treated and carded wool, you can "hang" it over the dowels which is much more effective at breaking up internal standing waves.

Only thing is, you cannot glue steel to the panel

Ever tried epoxy resin?

Trouble is steel usually rings, but that may not be an issue at LF.

If you use some sort of damping material like treated and carded wool, you can "hang" it over the dowels which is much more effective at breaking up internal standing waves.

Only thing is, you cannot glue steel to the panel

Ever tried epoxy resin?

Trouble is steel usually rings, but that may not be an issue at LF.

Volenti said:I used 16mm hardwood dowel with a looong 16mm drill to go straight from one side to the other, no messy measuring, just slide the dowel in, trim off, and glue in place

Of course, once the panel sides are cut, you could clamp them together and use a speedbore before assembly.

Curious Volenti, whats the driver and enclosure type?

pine, "softwoods" : fine, use very dry quality, use only to take force in one direction. = only F(N) > 0, no F(Q)

steel: problem is to make a connection without a slit between that differen materials. Also it may ring. Bad idea.

MDF, every kind of wood fiber based material: will be less strong against bending / torque than real wood used in right direction. I would call these kind of materials dirt - based.

real hardwood, like maple, wonderfull, but you need to know how to use.

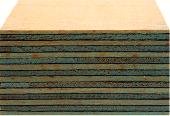

thick construction birch plywood, way to go. stiff on all directions, less problems with expanding uneqal with humidity. Use PVAC glue.

steel: problem is to make a connection without a slit between that differen materials. Also it may ring. Bad idea.

MDF, every kind of wood fiber based material: will be less strong against bending / torque than real wood used in right direction. I would call these kind of materials dirt - based.

real hardwood, like maple, wonderfull, but you need to know how to use.

thick construction birch plywood, way to go. stiff on all directions, less problems with expanding uneqal with humidity. Use PVAC glue.

Attachments

Brett said:

Of course, once the panel sides are cut, you could clamp them together and use a speedbore before assembly.

Curious Volenti, whats the driver and enclosure type?

good point.

I'm using 2x JL15w-6 (car audio long throw subs, very similar to Adrie's tempest, but with dual 6 ohm voice coils) in push push with a driver on either side to cancel mechanical vibrations, the enclosure is divided in 2 with each sub in a seperate 85L sealed enclosure(stuffed with dacron and lined behind the drivers).

Brett said:Try dried hardwood dowel 20-30mm diameter. Drill a pilot hole through the panel into the end of the dowel and screw up tight.

This sounds like a good method. Something that might make it even better is to give the end of the dowel greater resistance to splitting and possibly a better grip on the screw by putting a hose clamp around the end of the dowel. Sort of like that clamp the dentist puts around a molar tooth to hold it together when he is giving you a really big filling. 😱

Attachments

Graham, the hose clamp would work, but if you drill the correct size hole and use a matching crew, splitting shouldn't be an issue.

You could also dip the ends of the dowel in thinned epoxy resin and allow them to dry before placing them.

There are lots of ways of doing this sort of stuff, and ingenuity and resourcefullness are the best methods.

You could also dip the ends of the dowel in thinned epoxy resin and allow them to dry before placing them.

There are lots of ways of doing this sort of stuff, and ingenuity and resourcefullness are the best methods.

let me know if this is a stupid idea but once the dowel is in maybe you could hit a nail into the end to force the end of the dowel to push hard against the side so that it holds even better. and to get the nail flush hit it in with one of those metal things that lets it go below being flush. then use a bit of filler.

michael said:let me know if this is a stupid idea but once the dowel is in maybe you could hit a nail into the end to force the end of the dowel to push hard against the side so that it holds even better. and to get the nail flush hit it in with one of those metal things that lets it go below being flush. then use a bit of filler.

Yea you could do that, would be usefull if the drill hole was a little too large, (or the dowel being too small) though generally if it's a nice fit the pva glue bond usually ends up being stronger than the host wood anyway.

Is the consensus that steel is a bad idea? I have a bunch of 1.5" hollow steel pipe lying around that is very, very strong. I was thinking about stuffing it with polyfill and damping the outside with rubberized undercoat.

Question 2: it would be great to couple the driver to the back wall. I can't seem to think of a good way to firmly attach the bracing rod to the driver though. Any thoughts?

Question 2: it would be great to couple the driver to the back wall. I can't seem to think of a good way to firmly attach the bracing rod to the driver though. Any thoughts?

tiroth said:Is the consensus that steel is a bad idea? I have a bunch of 1.5" hollow steel pipe lying around that is very, very strong. I was thinking about stuffing it with polyfill and damping the outside with rubberized undercoat.

Question 2: it would be great to couple the driver to the back wall. I can't seem to think of a good way to firmly attach the bracing rod to the driver though. Any thoughts?

I used steel angle iron to brace the edges of my open baffles with no noticable negative side effects, though they were heavily damped by the silicone adhesive that I used.

Q2; I've always just used beam braces from the edge of the driver cut out hole to the back of the enclosure, too much of a PIA and diminishing returns to attack the driver directly in that way.

pack the pipes with fine sand, will damp better than dacron.

I had thought of using pipes going from one box wall to the other with a length of threaded rod going through the middle, and poke the ends of the rod through to the outside of the box and put a nut and a very large washer on each end. This would be unbelievably strong but would probably also re-define the word "ugly".tiroth said:I have a bunch of 1.5" hollow steel pipe lying around that is very, very strong. Any thoughts?

What about this. At each attachment point, you cut a pair of slots all the way through the pipe, perpendicular to each other. Make the first 0.25" from the end, the second 0.375". Slide some 1/2" wide bar stock through each slot, making an 'X' of metal. Add some 0.25" and 0.375" thick bar as shims, and you have a very sturdy internal attachment.

Of course, this is really on feasible for hollow pipe. 😉

Of course, this is really on feasible for hollow pipe. 😉

Circlotron, I've had that thought many times. The only way I can think of doing it and making it look nice would be to have ultra think side panels, and then to flush-mount the nut, by coutersinking a big fat hole. But this would need some thick walls...

In my ported Tempest sub I have threaded bolts running through the braces to tightly tie them together. I've no idea if it adds any qualities (rigidity), but it was fun to make!

At moderate volumes the sub noticably wobbles to the touch! Its either flexing (18mm MDF mostly) or resonates at quite a low frequency! (<50hz) I care not, my next one will probably be push push, and sealed (less huge!).

-Simon

In my ported Tempest sub I have threaded bolts running through the braces to tightly tie them together. I've no idea if it adds any qualities (rigidity), but it was fun to make!

At moderate volumes the sub noticably wobbles to the touch! Its either flexing (18mm MDF mostly) or resonates at quite a low frequency! (<50hz) I care not, my next one will probably be push push, and sealed (less huge!).

-Simon

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Brace material - various woods, steel etc.