I have just finished a small class A amp, the K10A and I thought this world be perfect for my home office. I saw this as an opportunity to build (yet another  ) a pair of speakers and use up some of the drivers I have laying around.

) a pair of speakers and use up some of the drivers I have laying around.

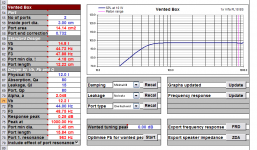

I wound up using the Vifa PL18 for the mid-bass and something a bit different for the tweeters. I used Unibox to determine the best box size and tuning, keeping in mind the end purpose. The office is not big and space is limited so I would need to compromise. Ideal vented box size for the PL is ~18 litres (giving an F3 of ~41Hz) but this was just a bit bigger than I wanted.

12 litres is more like it and the low end response still looks very reasonable at an F3 of ~49Hz.

I wound up using the Vifa PL18 for the mid-bass and something a bit different for the tweeters. I used Unibox to determine the best box size and tuning, keeping in mind the end purpose. The office is not big and space is limited so I would need to compromise. Ideal vented box size for the PL is ~18 litres (giving an F3 of ~41Hz) but this was just a bit bigger than I wanted.

12 litres is more like it and the low end response still looks very reasonable at an F3 of ~49Hz.

Attachments

With only 10 watts, it's obvious that I'm not going to break any SPL records. I would have liked higher efficiency but that would mean buying more new stuff. My new policy - out with the old before in with the new.

Box size and alignment issues out of the way I look to an idea that's been rolling around in my head for a while: a solid wood baffle with a tweeter wave guide carved in. Yes, solid wood. Yes, carved in.

The tweeter is a 2" paper cone salvaged from an old find. Not high quality by any means but I did test their frequency response and listened to how they sound and they are more than acceptable on both fronts. It starts to roll off at ~14k (just like what's left of my hearing ) but they are very linear, very smooth.

Doing some work around the house last summer, I had an off cut of a 2 x 10, just an ordinary hunk of spruce lumber. It was fairly straight grained and free of major defects and knots, long enough to get two baffles.

Of course this is solid wood and I've done my share of preaching about not using it for speakers. The biggest reason is the initial shrinkage after assembly and there is also seasonal expansion and contraction that can work to break joints. The wood felt dry but I didn't want to take any chances on it cracking after the speaker is put together so I put it in the "kiln". This is my kitchen oven and I "cooked" it at 300 degrees on convection for 30 minutes. I repeated this cooking 3 more times over the next 3 days. In this time the width went from 9.125 inches down to 8.875 - that's 1/4" shrinkage. I left them in the office for a week to acclimate to the moisture level there before doing any work on them.

and I "cooked" it at 300 degrees on convection for 30 minutes. I repeated this cooking 3 more times over the next 3 days. In this time the width went from 9.125 inches down to 8.875 - that's 1/4" shrinkage. I left them in the office for a week to acclimate to the moisture level there before doing any work on them.

Layout and cut the recess for the woofer and do a rough gouging out of the waveguide:

Then lots of sanding. Luckily spruce is pretty soft - sanding it is easy and it doesn't gum up the paper, disks and belts like pine does.

Box size and alignment issues out of the way I look to an idea that's been rolling around in my head for a while: a solid wood baffle with a tweeter wave guide carved in. Yes, solid wood. Yes, carved in.

The tweeter is a 2" paper cone salvaged from an old find. Not high quality by any means but I did test their frequency response and listened to how they sound and they are more than acceptable on both fronts. It starts to roll off at ~14k (just like what's left of my hearing ) but they are very linear, very smooth.

Doing some work around the house last summer, I had an off cut of a 2 x 10, just an ordinary hunk of spruce lumber. It was fairly straight grained and free of major defects and knots, long enough to get two baffles.

Of course this is solid wood and I've done my share of preaching about not using it for speakers. The biggest reason is the initial shrinkage after assembly and there is also seasonal expansion and contraction that can work to break joints. The wood felt dry but I didn't want to take any chances on it cracking after the speaker is put together so I put it in the "kiln". This is my kitchen oven

Layout and cut the recess for the woofer and do a rough gouging out of the waveguide:

Then lots of sanding. Luckily spruce is pretty soft - sanding it is easy and it doesn't gum up the paper, disks and belts like pine does.

I'll be interested to hear about your results with regards to potential cabinet colouration. With luck it'll make everything sound like a classical guitar - but the grain isn't tight enough

Spruce is fairly stable and once you get a sealant on it you wont have any problems.

Have fun sanding out the wave guides!!

Spruce is fairly stable and once you get a sealant on it you wont have any problems.

Have fun sanding out the wave guides!!

lazyfly said:I'll be interested to hear about your results with regards to potential cabinet colouration. With luck it'll make everything sound like a classical guitar - but the grain isn't tight enough

Have fun sanding out the wave guides!!

Hi lazyfly,

The baffle is nearly 1.5 inches thick so I don't think there will be any resonance issues.

Sanding is all done days ago. I mounted the tweeter to do some frequency response tests to see if I was doing more harm than good and further refined the horn with more measurements in between. It looks good now, measurement wise.

planet10 said:Can you post a pic of the tweeters?

Hi Dave,

The tweeters were from a pair of old Lloyds speakers, talked about

here. Nothing special but they do sound pretty good and measure reasonable. I thought they would be a good fit here.

Attachments

Really nice job on the waveguides John.

Those little 2" thimble tweeters really puch way above their weightclass... they can be improved by fitting phase plugs... these experimental ones were made with shortened foam ear plugs.

The idea of wave guide loading them isn't new... you'll on occasion find them attached to plastic waveguides in Lloyds-class speakers, althou i suspect in those cases it was more about marketing & bling than sonics.

dave

Those little 2" thimble tweeters really puch way above their weightclass... they can be improved by fitting phase plugs... these experimental ones were made with shortened foam ear plugs.

An externally hosted image should be here but it was not working when we last tested it.

The idea of wave guide loading them isn't new... you'll on occasion find them attached to plastic waveguides in Lloyds-class speakers, althou i suspect in those cases it was more about marketing & bling than sonics.

dave

planet10 said:

Really nice job on the waveguides John.

Thanks Dave.

planet10 said:

Those little 2" thimble tweeters really puch way above their weightclass... they can be improved by fitting phase plugs... these experimental ones were made with shortened foam ear plugs.

I considered the phase plug and may give it a try. I have 4 of these so 2 to experiment with. What effect will it have on the response?

planet10 said:

The idea of wave guide loading them isn't new... you'll on occasion find them attached to plastic waveguides in Lloyds-class speakers, althou i suspect in those cases it was more about marketing & bling than sonics.

I did it for looks but also to try to improve the efficiency of the tweeter a bit (it has). I have one completed now, minus the crossover. Working on the crossover design with the DCX2496, making real time adjustments to determine the best point and slopes.

lazyfly said:Really nice work MJ!

Solid timber is the bee's knee's

Thanks lazyfly,

Even withe the drying that I did, there's no guarantee that the baffle won't split. To fight the seasonal expansion and contraction I rabbited the baffle to receive the sides, top and bottom and used #20 biscuits to reinforce the joints. Lots of yellow carpenters glue and clamped up over night.

The baffle has been sealed inside and out several time to stop moisture absorption.

I considered just a clear finish for the baffle but got inspired. I grabbed my propane torch and seared the wood, rubbed it down with steel wool and repeated the burning/rubbing until I had even colour and a pronounced grain. A rubbed on coat of mahogany stain and a few coats of clear urethane. It still needs to be rubbed down with steel wool again and waxed to give a satin lustre.

MJL21193 said:I considered the phase plug and may give it a try. I have 4 of these so 2 to experiment with. What effect will it have on the response?

In theory, more top and more coherence due to halving the size of the resonant cavity formed by the "dish" of the cone. Also gets rid of the cavity (oli can) resonance of the empty space in the voice coil.

I got the idea from Disk Sequerra

An externally hosted image should be here but it was not working when we last tested it.

I did it for looks but also to try to improve the efficiency of the tweeter a bit (it has)

Should be mostly at the low end of its passband... should also lead to less flare in the dispertion where the tweeter takes over.

dave

planet10 said:

In theory, more top and more coherence due to halving the size of the resonant cavity formed by the "dish" of the cone. Also gets rid of the cavity (oli can) resonance of the empty space in the voice coil.

I did it, just need to let the silicone that I glued it in with dry. Quickly done with 1/2" dowel and my drill:

If I like the results, I'll do a better job of a pair from maple then paint them black.

Until I can test the tweeter with the phase plug, I can do no more crossover design.

Here's how the "finished" one looks "in situ". It's the one I have been testing and for it's size, it has extraordinary bass. I put the ports (two, 3cm tubes) at the top of the box. Originally I planned on putting them in the front but it would have ruined the appearance IMO. Having them on top discourages me from piling papers on there.

planet10 said:Cute amplifier too...

Thanks Dave, though "cute" wasn't the adjective I was shooting for. That's ok.

I haven't done anything new with this project. I still need to test the tweeter with the phase plug mod and give it a listen. I can say that I have been listening to the first speaker ever since and I like what I hear. Bass is very good for such a small speaker and the midrange is very clean - the Vifa PL drivers are excellent in that range. Highs are smooth.

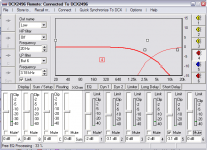

It is currently running from the DCX with a first order Butterworth on the midwoof and a 2nd order LR on the tweeter at ~3k. This seems to be what sounds good and also measures nearly flat. I expect this to be close to the final alignment.

Attachments

despotic931 said:Excellent job with the wave guide John! How did you figure out the dimensions for it?

- Justin

Thanks Justin,

I guessed

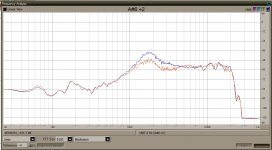

No sense lying about it and making it sound like I used a complex math formula or a puzzling simulation program. I whittled and sanded, measured and sanded some more. The truth is that I didn't expect much from this but I have been proven wrong once again. It gave an almost 5db+ increase, but in the wrong area. As Dave said, the gain was mostly at the lower part of the response. The tweeter already had a bump in it's response there, so this made it worse. See attached pic. The blue trace is the horn loaded with phase plug.

Now, I'm crossing the tweeter high ~3k so with a steep enough high pass filter I will cut most of it out. Does this sound like a waste of time?

They look cool though. They sound good - so far I have the crossover nearly worked out but it isn't going to be pretty. I think I need to try a shorter phase plug - this one is causing some ragged response up high (see in the attached pic).

Attachments

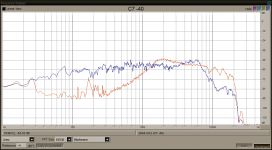

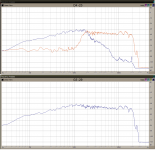

Here I have the far field response of both driver in the box. These are straight, without crossovers. These measurements were taken at the same output volume and the mic was the same distance from the driver for both (about halfway between the centre of the tweeter and the centre of the woofer). They are fairly close, efficiency wise.

Attachments

Using the DCX2496 and 2 amps I can get a good approximation of what the crossover points and slopes should be. Below (as above) are actual measurements. The plot on top shows the correction to the response for each driver. The tweeter corner frequency is at ~3k and cuts that hump down to usable response, lowering the actual crossover point. The woofer corner frequency is ~2.2k... yes a .8k gap between points but, as it can be seen in the plot on the bottom, overall response is fairly smooth.

Slopes are 4th order LR on the woofer and 4th order Butterworth on the tweeter. I will do some more testing to see if I can simplify these filters a bit - I'm not a big fan of anything passive over 2nd order.

Slopes are 4th order LR on the woofer and 4th order Butterworth on the tweeter. I will do some more testing to see if I can simplify these filters a bit - I'm not a big fan of anything passive over 2nd order.

Attachments

MJL21193 said:

Thanks Justin,

I guessed

No sense lying about it and making it sound like I used a complex math formula or a puzzling simulation program. I whittled and sanded, measured and sanded some more. The truth is that I didn't expect much from this but I have been proven wrong once again. It gave an almost 5db+ increase, but in the wrong area. As Dave said, the gain was mostly at the lower part of the response. The tweeter already had a bump in it's response there, so this made it worse. See attached pic. The blue trace is the horn loaded with phase plug.

Now, I'm crossing the tweeter high ~3k so with a steep enough high pass filter I will cut most of it out. Does this sound like a waste of time?

They look cool though. They sound good - so far I have the crossover nearly worked out but it isn't going to be pretty. I think I need to try a shorter phase plug - this one is causing some ragged response up high (see in the attached pic).

lol, well trial and error is sometimes the only way to know! And yes, they do look cool! I would love to do something like that sometime. Sadly I am far away from the nearest shop I am allowed to use. So all speaker projects are on hold till the summer...

-J

Looking great! That waveguide sure must have been difficult but it does look awesome  . Time aligned?

. Time aligned?

When I saw that bump in the tweeter response I thought you could help alleviate it by moving the crossover points respectively, and thats just what you've done . Should work well and could help lower distortion around the crossover by the tweeter having that extra efficiency. Could you try it with 12db filters or mabye you did and it was unacceptable?

. Should work well and could help lower distortion around the crossover by the tweeter having that extra efficiency. Could you try it with 12db filters or mabye you did and it was unacceptable?

When I saw that bump in the tweeter response I thought you could help alleviate it by moving the crossover points respectively, and thats just what you've done

great woodwork!

what I would try, would be a simpel 1st order (electrical) for the tweet so that the hump is flattened (looks smooth enough, so this might work) and match the woofers LP to the accoustic roll-off that results of this.

yep, that's the idea of a waveguide isn't it? can you also measure distortion with your kit? then you could see how low is still safe to cross.Dr.EM said:..... and could help lower distortion around the crossover by the tweeter having that extra efficiency.

what I would try, would be a simpel 1st order (electrical) for the tweet so that the hump is flattened (looks smooth enough, so this might work) and match the woofers LP to the accoustic roll-off that results of this.

Dr.EM said:Looking great! That waveguide sure must have been difficult but it does look awesome. Time aligned?

Could you try it with 12db filters or mabye you did and it was unacceptable?

Hi Dr.EM,

Thanks, it wasn't that hard at all actually. Took most of it out with a chisel then some careful work with the small sanding drum in the Dremel. Cleaned it up with hand sanding. Spruce is really soft and doesn't gum up the sandpaper.

Yes, one of the advantages of this shallow horn is to time align the drivers on a flat baffle.

I need some time to work with it, measuring the response with different filters. Fortunately, the digital crossover makes this an easy task. To build passive filters that match the results of the active crossover will probably be a different story...

Henkjan said:great woodwork!

yep, that's the idea of a waveguide isn't it? can you also measure distortion with your kit? then you could see how low is still safe to cross.

what I would try, would be a simpel 1st order (electrical) for the tweet so that the hump is flattened (looks smooth enough, so this might work) and match the woofers LP to the accoustic roll-off that results of this.

Hi Henkjan,

I have a mid woofer that has very good midrange response, so I want to utilize that to maximum effect. It has a rising response too though and it needs to be trimmed.

I like what I hear from the configuration above, maybe 3db of baffle step correction at 400Hz would be an improvement.

The 1st order on the tweeter would not reduce the hump in the response enough. I think I'd need at least a second order slope, maybe with the corner frequency higher - say 4k.

More experimenting is needed.

As for distortion measurements, I'm not exactly sure how to go about it. Record the speaker playing a specific frequency and comparing that to the original? Or a 1k sine wave through the speaker, recorded and do an fft?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Bookshelf speakers with a tweest.