hello! im looking for advice please, on how to bond gatorfoam / gator board. it was recommended to me by member Buckapound, as a lightweight alternative to wood.

im building a big old square 80's throwback boombox, and wood is too heavy.

i managed to get 10 sheets of the stuff sent to me. each board is 30 x 40 inches, and just over 1/8th of an inch.

i plan on, - actually, ill just paste in Buckapounds advice, he said it better than i could. -

Post #9

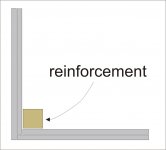

The Gatorfoam is amazingly rigid for how light and cheap it is. I made my boombox prototype out of two layers of plain old Foam-Core, and even that sounded pretty good. If you wanted a little extra strength, you could use two layers of 1/4" Gatorfoam laminated together with urethane caulk, which has great damping properties as a bonus. Two layers means more stuff to cut, but if you do it right, you can stagger the sizes of the sheets (the equivalent of a rabbet joint in woodworking) so the inside panels are smaller than the outside, and then you have this stairstep joint that glues up a lot stronger than just two plain pieces, plus leaves less of the soft foamy middle exposed.

so thats what ill do. i aint got no tablesaw but i think theres a carpentry or metalwork section in our college, hopefully theyll have a guillotine.

the bit im confused by, is how to bond the front to the sides and the back.

im thinking an epoxy? if anyone can offer any insight or advice ill lap it up!

thanks for reading, ned .

im building a big old square 80's throwback boombox, and wood is too heavy.

i managed to get 10 sheets of the stuff sent to me. each board is 30 x 40 inches, and just over 1/8th of an inch.

i plan on, - actually, ill just paste in Buckapounds advice, he said it better than i could. -

Post #9

The Gatorfoam is amazingly rigid for how light and cheap it is. I made my boombox prototype out of two layers of plain old Foam-Core, and even that sounded pretty good. If you wanted a little extra strength, you could use two layers of 1/4" Gatorfoam laminated together with urethane caulk, which has great damping properties as a bonus. Two layers means more stuff to cut, but if you do it right, you can stagger the sizes of the sheets (the equivalent of a rabbet joint in woodworking) so the inside panels are smaller than the outside, and then you have this stairstep joint that glues up a lot stronger than just two plain pieces, plus leaves less of the soft foamy middle exposed.

so thats what ill do. i aint got no tablesaw but i think theres a carpentry or metalwork section in our college, hopefully theyll have a guillotine.

the bit im confused by, is how to bond the front to the sides and the back.

im thinking an epoxy? if anyone can offer any insight or advice ill lap it up!

thanks for reading, ned .

- Status

- Not open for further replies.