Hello,

Is there someone who knows How it comes that Bl drops when the displacement become larger of the overhung voicecoil? Even when the coil is inside the gap Bl drops quite a bit.

Thx for helping me out.

Is there someone who knows How it comes that Bl drops when the displacement become larger of the overhung voicecoil? Even when the coil is inside the gap Bl drops quite a bit.

Thx for helping me out.

Perhaps it's not possible to concentrate all the magnetic smoke in the airgap, some is leaking out above and under the gap.

Or perhaps the magnetic field is influenced bij the current in the v.c necessary for the displacement.

Or perhaps the magnetic field is influenced bij the current in the v.c necessary for the displacement.

Last edited:

Hello,

Is there someone who knows How it comes that Bl drops when the displacement become larger of the overhung voicecoil? Even when the coil is inside the gap Bl drops quite a bit.

Thx for helping me out.

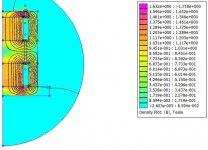

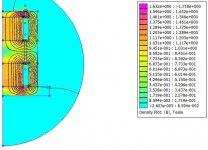

Essentially B drops above and below the gap. Even within the gap (between the front and back of the top plate) B will not be constant and will peak at about the center of the top plate.

Bl is essentially an integration over an interval equal to the coil length. This makes sense because the windings are equally spaced, so the coil just sees an average of the B covered by its instantaneous position.

Since the B field is non flat within the gap and falls rapidly outside the gap, Bl will always peak at more or less the centered position and fall off to either side.

On the other hand, if you design a short coil, long gap motor you will find that the B in the gap tends to be more constant and the Bl vs. X is quite a bit more constant. It does fall off very quickly when you get to the edge of the gap, though.

David

In many cases the pole faces are not truly concentric or machined to a close tolerance and smooth finish.These anomalies will give an uneven flux distribution within the gap and more so for the long gap motor.

Oké I get it. So the roll off on the edge is very important to maintain linearity.

Why do most manufacturers use straight polepieces like in the example? This is not good for lineairity (low roll off on the edge)

Would this not to be better? (don't look at the double gap)

With a higher roll off.

thx,

Why do most manufacturers use straight polepieces like in the example? This is not good for lineairity (low roll off on the edge)

Would this not to be better? (don't look at the double gap)

With a higher roll off.

thx,

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Bl - x curve