Computer CPUs are often running at consistently-high load. For example, when doing video renders, playing graphically-intensive games, etc. In many of these situations it doesn't matter how much thermal mass there is, the cooler just needs a way to effectively flow it all way as quickly as possible."Buffered" was perhaps a poor word choice. The point is, the thick base allows rapid spikes in heat production (like in the case of a CPU ramping up under load) to be readily absorbed away from the heat source. Just look at any high performance CPU heat sink and you can see that they are designed with this in mind - some of them with thick, heavy cores of copper. The exception is coolers with heat pipes; since they are far more effective at moving heat (via the pipes) away from the source, they do not require nearly as much mass at the base to absorb rapid spikes of heat.

The resistor analogy is off the mark. The physics isn't comparable, IMO.

Looking at almost all modern (high-power) coolers, none have "massive" blocks contacting the CPU. That's basically 2000-era technology.

EDIT: I'm trying to find, without any success, a photo of an old heatsink called the "Core". It was basically a ~3"x3" block of metal with a bunch of big holes cross-drilled through it, kind of like a 1-2-3 block but more cubical. It did not work well.

Last edited:

Of course the heat sink has to also function under consistent load. I never said it didn't.

So you are talking about heat pipes. Just like I said.

If the thick base on standard CPU heat sinks (those not employing heat pipes) provides no thermal function, can you explain why manufacturers would waste money designing it that way?

So you are talking about heat pipes. Just like I said.

If the thick base on standard CPU heat sinks (those not employing heat pipes) provides no thermal function, can you explain why manufacturers would waste money designing it that way?

Last edited:

I have 3 adult daughters. All left home. One is doing a PhD in France, one is about to qualify as a midwife and one is about to become a teacher. All doing what they wanted to do and with no pushing. And that's despite their parents. So I disagree with your assessment.

That's awesome. There's kids like that here but in my experience they're immigrants, or children of immigrants. My new neighbor is 30ish and works during the day and goes to school at night. He's working his way up in construction management. But he's from Ghana. His wife is from a wealthy local Jewish family. I made friends with her father right away and he's grumpier than me. He's also grateful his daughter didn't marry run of the mill slacker.

In fairness, work isn't the same deal it was when I was young. It was easy to get a job, and easy to get a better job. Everybody wanted to hire you. Jobs came with benefits like health insurance and paid vacation. Those are considered perks now; no longer de rigueur. Employers competed to recruit you. Poaching employees was the order of the day. Employers handed out raises several times a year just so you wouldn't leave.

And health insurance is way out of reach for millions of working Americans, including me. In fact, they've distorted the job market here so badly that in my opinion it's barely worth working any more. I'm just limping along for the next few years until I can get Medicare. Then I can start going to a real doctor again. Because for me to get "affordable" health insurance, I would have to sell my house and spend down my meager savings.

They sure changed things a lot. It's a raw deal. I wish a better system than this for our future generations. The present system is eating away at the middle class.

Some may argue that the function of the thick base is to minimize "spreading resistance". The formula for that can be easily optimized. Yet, modern CPU heat sink designs often go far beyond the optimal base thickness required to minimize spreading resistance.

Here is a modern AMD Ryzen heat sink, as an example. The copper/aluminum core is approximately half as thick as the overall heat sink.

Here is a modern AMD Ryzen heat sink, as an example. The copper/aluminum core is approximately half as thick as the overall heat sink.

That copper piece is actually a "vapor chamber" (don't ask me).

Interestingly, the cost-cutting evolution of that cooler you pictured had the vapor chamber removed. This led to a degradation of performance of anywhere between 2-5 full degrees C under load (with the same fan noise) compared with the unit that had the vapor chamber. The performance of the vapor chamber-less cooler was ultimately equivalent, though, albeit with much higher fan noise (higher fan RPM to increase cooling).

AMD Wraith Spire vs. Wraith Spire, Copper Vapor Chamber Gone! [Hardware Unboxed] : hardware

Interestingly, the cost-cutting evolution of that cooler you pictured had the vapor chamber removed. This led to a degradation of performance of anywhere between 2-5 full degrees C under load (with the same fan noise) compared with the unit that had the vapor chamber. The performance of the vapor chamber-less cooler was ultimately equivalent, though, albeit with much higher fan noise (higher fan RPM to increase cooling).

AMD Wraith Spire vs. Wraith Spire, Copper Vapor Chamber Gone! [Hardware Unboxed] : hardware

Last edited:

whilst we are talking heatsinks does anyone have a photo of the bonkers water cooled mainframe heatsinks IBM used to do where they baked a ceramic block with the PCB tracks on.

That copper piece is actually a "vapor chamber" (don't ask me).

Heat pipe

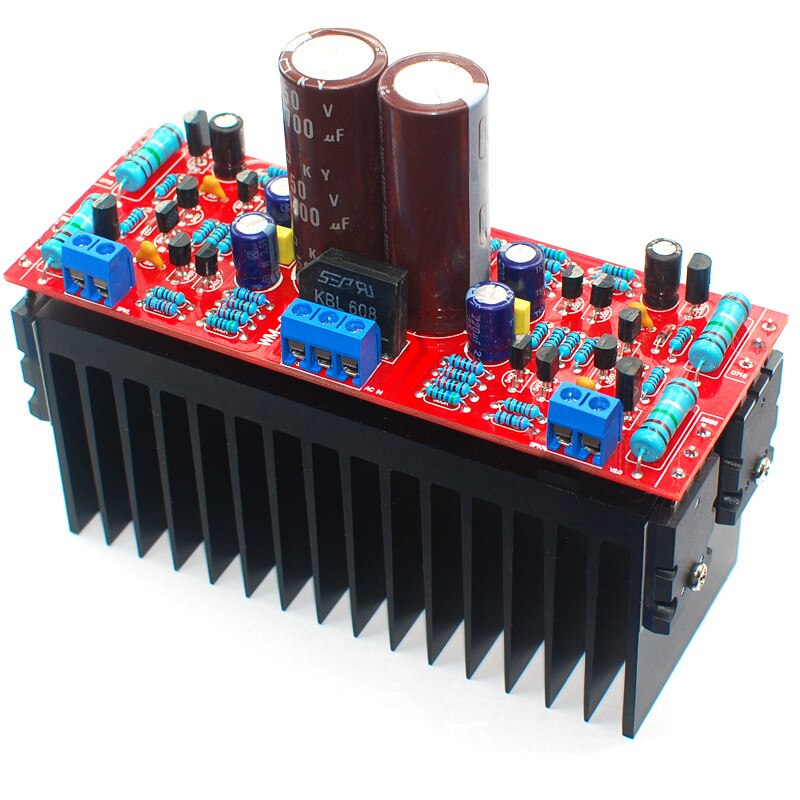

Now let's consider again the thermal solution in question earlier.

The heat sink's thicker base provides low enough spreading resistance to conduct heat to the attached fins. The heat sources are not located optimally, however parts of each are directly interfaced with the base and the base has much lower thermal resistance than the fins, therefore the bulk of the heat will readily spread through the base and into the other fins. End of story. Not optimal, but very likely adequate (esp. if the modules are oriented in a way to encourage convective release of heat from the fins).

The heat sink's thicker base provides low enough spreading resistance to conduct heat to the attached fins. The heat sources are not located optimally, however parts of each are directly interfaced with the base and the base has much lower thermal resistance than the fins, therefore the bulk of the heat will readily spread through the base and into the other fins. End of story. Not optimal, but very likely adequate (esp. if the modules are oriented in a way to encourage convective release of heat from the fins).

Last edited:

Agreed. As long as the design stays within SOA, who cares? 😉 It does make assembly a bit easier.

Is a heat pipe and a vapor chamber like having water in a strong vacuum, so it boils a slightly above ambient temperature ( absorbing LOADS of thermal energy), then condensing higher up to recirculate ?

Qualifying humans to become parents - successfully raise a dog. "My parents shouldnt have been allowed to have a dog... Pretty low blow, right? Let's have a look at that..."

I did a lot of test automation for the mechanical group when I worked at Intel. One of the last things I did in the heat sink test space was thermal transient testing of heat sink in airflow.

The idea was that the CPU was so fast and dissipated so much power, they could get more average performance bursting it. So they were very interested in the heat sink / case /die transient response and how that changed as a function of various flows across the fins.

Whatever thermal trickery they could successfully apply to squeeze out every last bit of performance. Apparently, there was no realistic thermal solution where they could just run it WFO - I was just the test guy and didnt know at which juncture things fell apart thermally.

I did a lot of test automation for the mechanical group when I worked at Intel. One of the last things I did in the heat sink test space was thermal transient testing of heat sink in airflow.

The idea was that the CPU was so fast and dissipated so much power, they could get more average performance bursting it. So they were very interested in the heat sink / case /die transient response and how that changed as a function of various flows across the fins.

Whatever thermal trickery they could successfully apply to squeeze out every last bit of performance. Apparently, there was no realistic thermal solution where they could just run it WFO - I was just the test guy and didnt know at which juncture things fell apart thermally.

But a roofspace heat exchanger to keep the air in the house fresh whilst minimising heat loss seems to me to be good technology. If only they didn't cost so much and fail so often...

Do you mean the system to use exiting used airs temperature to heat up incoming fresh air? That is a very good system and can be bought ready made but DIY is possible as well.

Since Covid focus is on good ventilation (thankfully) and these systems do just that while not wasting energy too much.

Last edited:

OK we use for a change not an English word for this. Translated we call it a "heat recovery system". I know a Spanish type which performs quite good, is affordable and has electronics for frost prevention in winter, fan rpm etc. I will search for name and type.

You can build those passive with PVC tubes with large diameter tubes when they are shoved in each other between 2 walls and some openings but it will not exactly look nice.

In large buildings me and colleagues never could see an advantage and many did not even understand what is was about. We thought them to be ill adjusted as we did not see or notice their efficiency. (in a very energy inefficient environment). In private homes however I have seen their results and liked them.

Found it, they have several models and the link leads to the smallest one:

ECOROOM – S&P – S&P

You can build those passive with PVC tubes with large diameter tubes when they are shoved in each other between 2 walls and some openings but it will not exactly look nice.

In large buildings me and colleagues never could see an advantage and many did not even understand what is was about. We thought them to be ill adjusted as we did not see or notice their efficiency. (in a very energy inefficient environment). In private homes however I have seen their results and liked them.

Found it, they have several models and the link leads to the smallest one:

ECOROOM – S&P – S&P

Last edited:

There used to be very nice heat exchangers ending in the skip when I worked at Nokia. I never kept one as I had no use for it.

Large buildings need full HVAC. I know not enough to be dangerous with that other than an awful lot of these buildings could cut energy consumption by 20-30% just by adjusting things properly. If only office buildings didn't need humans in it would be so much easier. I am sure you could tell me many beers worth of horror stories.

Large buildings need full HVAC. I know not enough to be dangerous with that other than an awful lot of these buildings could cut energy consumption by 20-30% just by adjusting things properly. If only office buildings didn't need humans in it would be so much easier. I am sure you could tell me many beers worth of horror stories.

No no horror stories but we were forced to have these air heat exchangers beside full HVAC. I like to adjust installations for optimal efficiency. I can tell horror stories of failing very high power switchgear, exploding UPSes if you like though 🙂

You are right about possible efficiency improvements. Many an installation company does not care and when the building is "delivered" not much chance of them coming back for fine tuning unless you were wise enough to include it in the contract.

BTW that Soler & Palau company produces one of the better working kitchen extractors. I saw it in Portugal where people really like to cook with dried fish and also other smelly fish dishes (IMO) and see the need for a good extractor. I saw it working there and noticed it has a detachable grease drain and you can easily take it completely apart to clean it. Too bad that I can't find it here. It's not about the looks here but about price, efficiency, functionality and air flow.

CK-50 *230V 50* – S&P – S&P

You are right about possible efficiency improvements. Many an installation company does not care and when the building is "delivered" not much chance of them coming back for fine tuning unless you were wise enough to include it in the contract.

BTW that Soler & Palau company produces one of the better working kitchen extractors. I saw it in Portugal where people really like to cook with dried fish and also other smelly fish dishes (IMO) and see the need for a good extractor. I saw it working there and noticed it has a detachable grease drain and you can easily take it completely apart to clean it. Too bad that I can't find it here. It's not about the looks here but about price, efficiency, functionality and air flow.

CK-50 *230V 50* – S&P – S&P

Last edited:

My Late ex-father in law was a quantity surveyor and he told me in the 1970s builders would put undersized air pipes in to save on capex. Due to reduced flow the air was overchilled then warmed again a significant amount before exit into the room. A few degrees I can understand but this was silly.

My current employers asked me a few years ago to look into the latest fad of smart buildings having sold the dream to a company with some 12,000 properties in the UK. It was a lovely dream, but the reality was that it would be cheaper to train up 200 people to spend their lives visiting these sites and checking things than try and come up with a central swamp of incompatible data. The tech is there, but the companies are 20 years behind and the cost/benefit curve goes vertical very quickly.

My current employers asked me a few years ago to look into the latest fad of smart buildings having sold the dream to a company with some 12,000 properties in the UK. It was a lovely dream, but the reality was that it would be cheaper to train up 200 people to spend their lives visiting these sites and checking things than try and come up with a central swamp of incompatible data. The tech is there, but the companies are 20 years behind and the cost/benefit curve goes vertical very quickly.

- Home

- Member Areas

- The Lounge

- Biggest engineering mistakes in audiophile gear