Hi,

Suppose we take a russian GU72 and run it on perhaps 320V and 20W instead of 600V and 60W or so, could we expect any ill effects on tube life?

I´m asking because I seem to recall something a friend mentioned long ago, something about certain tubes relying on some sort of auto-absorption instead of normal gettering to deal with outgassing. I´ve tried to google the subject without any useful results.

Suppose we take a russian GU72 and run it on perhaps 320V and 20W instead of 600V and 60W or so, could we expect any ill effects on tube life?

I´m asking because I seem to recall something a friend mentioned long ago, something about certain tubes relying on some sort of auto-absorption instead of normal gettering to deal with outgassing. I´ve tried to google the subject without any useful results.

Last edited:

Types with graphite anodes need to run red hot. Red hot graphite is self getting of any residual oxygen.

Types with graphite anodes need to run red hot. Red hot graphite is self getting of any residual oxygen.

My graphite-anode 833C tubes still have two silver getter spots on the glass. Belts and suspenders, perhaps.

Notice the gettering at the bottom of the glass in the picture.

Attachments

Last edited:

The anode structure's parts do kind of look zirconium coated - and that would be the getter if there's no barium flash anywhere else.

On the other hand, here's a page from a builder (around the corner from you , perhaps?) who uses it triode connected at something between five and six hundred volts. Maybe talk to him and see how long his tubes have lasted . . . . .

On the other hand, here's a page from a builder (around the corner from you , perhaps?) who uses it triode connected at something between five and six hundred volts. Maybe talk to him and see how long his tubes have lasted . . . . .

I'm not sold on graphite plates needing to be run red hot. Plenty of cheap 211 and 845s are graphite and you'll never see them red. Tantalum on the other hand, yes.

On the other hand, here's a page from a builder (around the corner from you , perhaps?) who uses it triode connected at something between five and six hundred volts. Maybe talk to him and see how long his tubes have lasted

Ah, I´ve met this fellow once or twice. Unfortunately, we both share the habit of not finishing our projects, which seems to be the case with his GU72 amp.

The GU72 is a bit of a strange critter. The datasheet mentions "cathode: indirectly heated" but the cathode is internally connected to one side of the heater. Warmup time is specified to 2 s, which seems a bit short for an indirectly heated tube?

Well, I see you've had conversation about this tube before. I hadn't noticed the cathode - heater connection the first time I looked at the sheet. It has its own pins though so I don't know why that would be a problem.

Anyway, back to the gettering. If indeed the anode has to be up to a certain temp to do it right then I'd just run the tube at the dissipation equivalent to what they have listed in the data sheet. Which is 54.4 watts if done by straight multiple of 800V x 68mA. At your suggested 380V that'll be 144mA. Mmmmmm juicy !

Nice to have those triode curves already done! . . . and they look pretty good! You've been around a while , you must have a few clip leads. Why not just clip one up and see ?

Oh! I just remembered reading something Tubelab wrote about sweep tubes crapping out when idling in triode class A. I wonder if the GU72 might be a good candidate for an Unset amp.

Anyway, back to the gettering. If indeed the anode has to be up to a certain temp to do it right then I'd just run the tube at the dissipation equivalent to what they have listed in the data sheet. Which is 54.4 watts if done by straight multiple of 800V x 68mA. At your suggested 380V that'll be 144mA. Mmmmmm juicy !

Nice to have those triode curves already done! . . . and they look pretty good! You've been around a while , you must have a few clip leads. Why not just clip one up and see ?

Oh! I just remembered reading something Tubelab wrote about sweep tubes crapping out when idling in triode class A. I wonder if the GU72 might be a good candidate for an Unset amp.

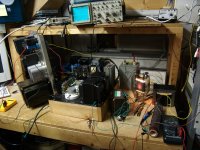

you must have a few clip leads

Ooh yes...!😀

Fact is, I ran some practical tests on this tube some years ago, IIRC I got ~15W in triode connection with 570V on the plate, 120mA and a 3,2k OPT with 20% CFB.

A rather exciting test, as the output transformer was homemade and not intended to run att such a high voltage and the tube ran hot enough to melt the solder joint on the top cap connector.

The latest idea is to use these tubes with a pair of James OPTs, rated 3,5K 55mA (the current rating can be pushed a little bit), simply using the tubes as if they were 6L6s or something and ignore the fact that they´re running at 1/4 capacity.

Quite a shotgun wedding perhaps, but it would be fun to use my GU72s without cashing up big for new transformers.🙂

Some tubes use a Zirconium Sponge gettering material rather the a flash of metal film on the glass envelope. The SV572 and SV811 suffered this problem, but not the plain old 811A.

I have 845s in service for 12 years running 430V @ 62ma - or 26W plate dissipation. They do not get very hot because the heat dissipates over a much larger surface area than say an EL34 run at the same point. The still sound and measure fine.

Use up the GU72 inventory while the tubes are still viable to be put to use... Nobody is going to be using them, they will all eventually go away some day when people stop caring about them in about 100 years. Go for it!

I have 845s in service for 12 years running 430V @ 62ma - or 26W plate dissipation. They do not get very hot because the heat dissipates over a much larger surface area than say an EL34 run at the same point. The still sound and measure fine.

Use up the GU72 inventory while the tubes are still viable to be put to use... Nobody is going to be using them, they will all eventually go away some day when people stop caring about them in about 100 years. Go for it!

A rather exciting test, as the output transformer was homemade and not intended to run att such a high voltage and the tube ran hot enough to melt the solder joint on the top cap connector.

Wonder if they were meant to have heat dissipating caps?

Anyone got pictures of graphite running red hot in normal operation? I'd like to see it.

All of my experiences with tubes meant to run red hot were tantalum plates.

All of my experiences with tubes meant to run red hot were tantalum plates.

Anyone got pictures of graphite running red hot in normal operation? I'd like to see it.

All of my experiences with tubes meant to run red hot were tantalum plates.

Last edited:

Some years a go I came to contact the engineer from GOGO Audio which had some power amps with GU72 at 600V and GMI11 also in low power.Hi,

Suppose we take a russian GU72 and run it on perhaps 320V and 20W instead of 600V and 60W or so, could we expect any ill effects on tube life?

I´m asking because I seem to recall something a friend mentioned long ago, something about certain tubes relying on some sort of auto-absorption instead of normal gettering to deal with outgassing. I´ve tried to google the subject without any useful results.

Log into Facebook

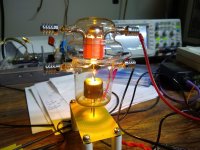

The 833A in the picture is running right at the 400 watt spec limit (old GE GL833A spec, old GE tube) Most 833A's have tantalum coated steel plates. They are rated to run red. Forced air cooling is needed to avoid damaging the seal at the plate and grid caps if prolonged operation in the red zone is involved. These tubes were used an AM radio broadcast transmitters where 24/7 operation "forever" was the norm.

Penta did market a graphite 833C with a carbon (graphite) plate. I have never had a Penta branded tube that lived long, so I never tried one. Graphite is a better thermal conductor than steel. This spreads the heat over a larger area making redness unlikely at or below the rated dissipation limit.

The graphite Chinese 845s in the picture are running at 125 watts, well over spec. The reddish color on the plates is not real (none observed by eye). My old Sony camera used in this nearly 15 year old picture has a lot of IR sensitivity, especially in this situation where the only light in the room came from the tubes. I do not run my NOS 845's or 211's beyond 75 watts.

I have pushed 813's to over 150 watts without glow. The 813 has a graphite plate with a 100 watt continuous duty rating, 125 watts for intermittent duty.

Penta did market a graphite 833C with a carbon (graphite) plate. I have never had a Penta branded tube that lived long, so I never tried one. Graphite is a better thermal conductor than steel. This spreads the heat over a larger area making redness unlikely at or below the rated dissipation limit.

The graphite Chinese 845s in the picture are running at 125 watts, well over spec. The reddish color on the plates is not real (none observed by eye). My old Sony camera used in this nearly 15 year old picture has a lot of IR sensitivity, especially in this situation where the only light in the room came from the tubes. I do not run my NOS 845's or 211's beyond 75 watts.

I have pushed 813's to over 150 watts without glow. The 813 has a graphite plate with a 100 watt continuous duty rating, 125 watts for intermittent duty.

Attachments

I've been dealing with 100T variants, and the older tubes with smooth tantalum plates show color very easily (50% of max dissipation or less). The later ones with rough dark-grey coatings don't seem to show color until above 80%(maybe those are tantalum-coated steel?).

From brief reading, it looks like graphite plates can be coated with Zirconium to act as a getter, but this isn't necessarily always done. In a tube with no other getter, it seems probable that the plate is the getter. I don't know if those work fine at lower temperatures or not. I've just read that the tantalum needs to be hot to work well.

From brief reading, it looks like graphite plates can be coated with Zirconium to act as a getter, but this isn't necessarily always done. In a tube with no other getter, it seems probable that the plate is the getter. I don't know if those work fine at lower temperatures or not. I've just read that the tantalum needs to be hot to work well.

Attachments

From the article linked above in post #7 . . . . "Zirconium metal is cheaper than tantalum and requires somewhat lower operating temperatures."

I routinely run my graphite 833C tubes red hot. 2300Va at 160mA, dissipating 330W at idle. Seven years and counting on this set of Machletts, only needed to adjust the bias once in that time. I have two more pairs branded Taylor. Don't let the names fool you, they are all new Chinese tubes.

Attachments

Last edited:

- Home

- Amplifiers

- Tubes / Valves

- Big tubes on low power