Pity I do not have 3D printing.

Very interesting results indeed. And, did you have the chance to measure off axis response as well?

Very interesting results indeed. And, did you have the chance to measure off axis response as well?

I just noticed this thread - I must try that trick too! I don't have access to 3D printing, so i takes some time to realize...

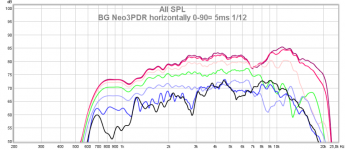

These measurements were at 1,5 meters and driver open back, turned 90¤ sideways (vertical directivity)

These measurements were at 1,5 meters and driver open back, turned 90¤ sideways (vertical directivity)

Attachments

To get started one would not need actual 3D printed parts, as it appears a half round molding of the correct size would work, or even using rope caulk or other hand-moldable squishy materials.

Thanks for sharing your measurements.These measurements were at 1,5 meters and driver open back, turned 90¤ sideways (vertical directivity)

This seems to confirm my thought that the measurements shown in post #1 are near field measurements.

I'm not sure how much response smoothing you will see at 1.5m from the addition of the half-round bars.

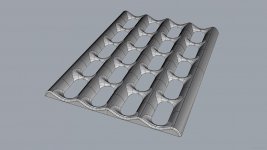

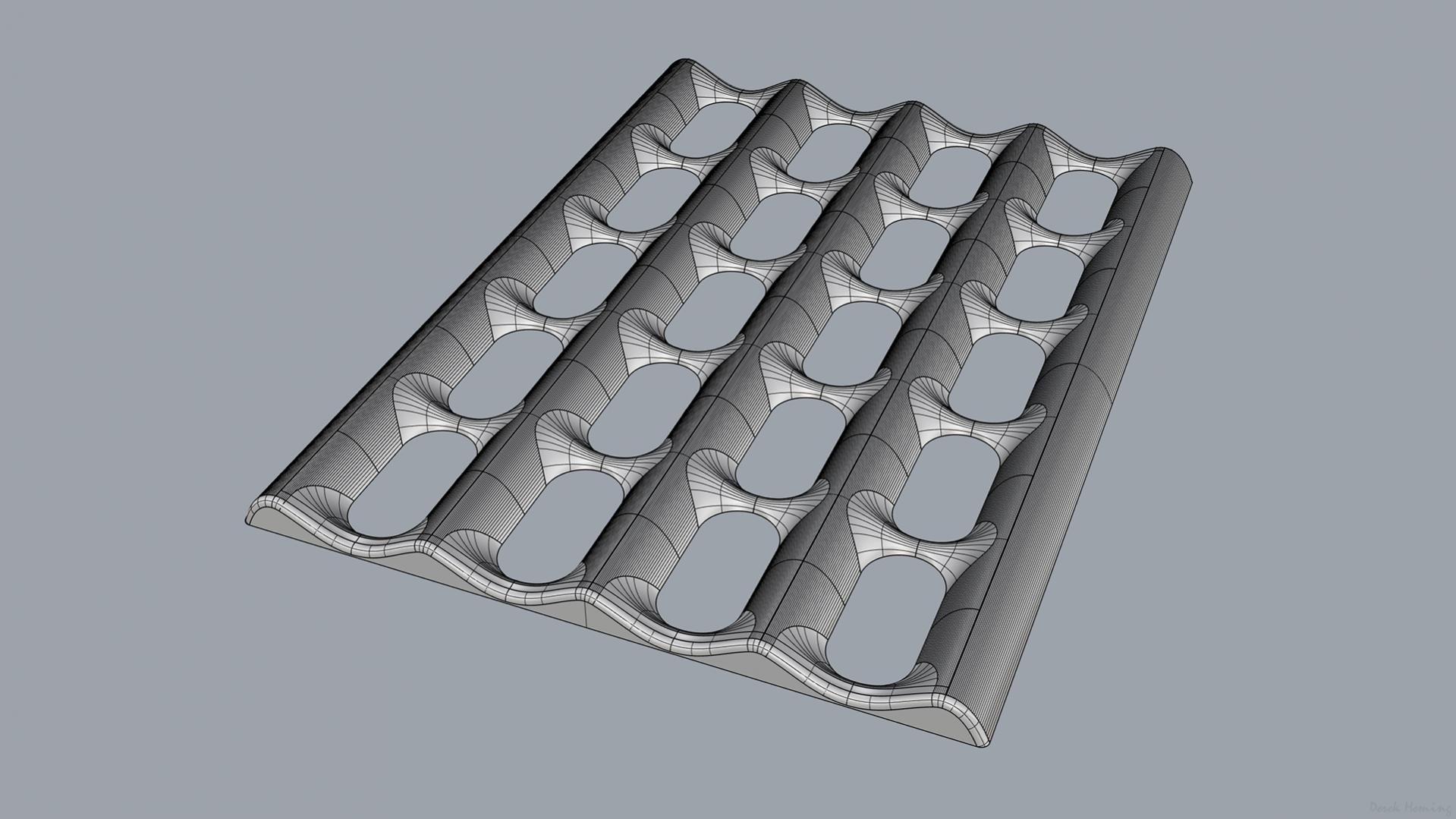

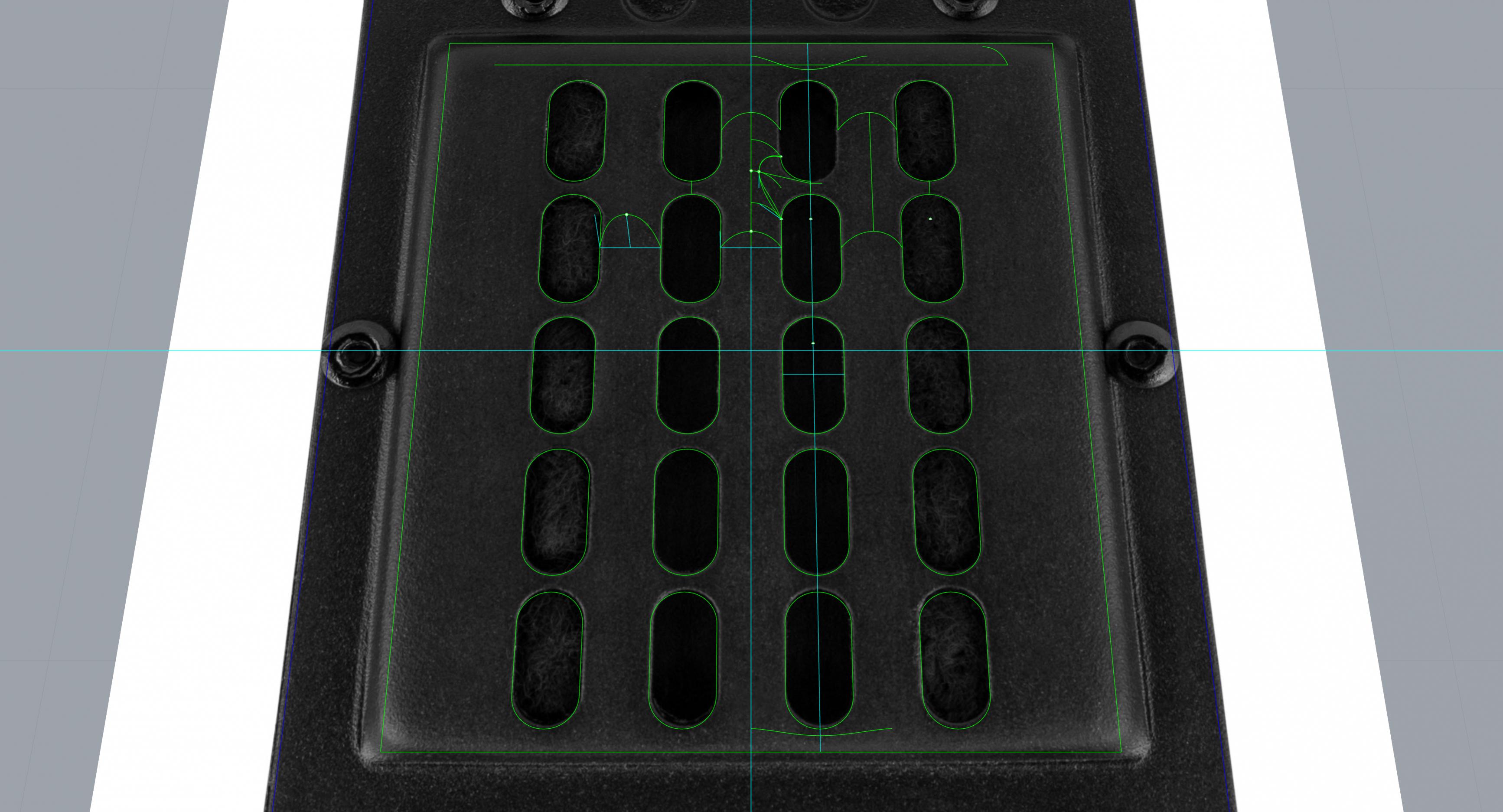

If simple half-rounds help that much I wonder what full waveguides at each individual opening would do? Like this:

All the curves are catenary in this 3D model. Should be easy enough to get 3D printed somewhere. I did the layout work from an image, but I have a pair of older Neo3-PDR tweeters in storage that I could get accurate measurements from using calipers.

All the curves are catenary in this 3D model. Should be easy enough to get 3D printed somewhere. I did the layout work from an image, but I have a pair of older Neo3-PDR tweeters in storage that I could get accurate measurements from using calipers.

Attachments

Hi all,

Just FYI Shapeways does 3D printing at an IMHO quite reasonable price. Their "frosted detail" materials is high precision and have a very smooth surface. Shapeways can use a variety of files formats and among those .stl files.

Frosted (Ultra) Detail Plastic 3D Printing Material Information - Shapeways

Cheers,

Jesper

Pity I do not have 3D printing.

Just FYI Shapeways does 3D printing at an IMHO quite reasonable price. Their "frosted detail" materials is high precision and have a very smooth surface. Shapeways can use a variety of files formats and among those .stl files.

Frosted (Ultra) Detail Plastic 3D Printing Material Information - Shapeways

Cheers,

Jesper

Hi all,

Just FYI Shapeways does 3D printing at an IMHO quite reasonable price. Their "frosted detail" materials is high precision and have a very smooth surface. Shapeways can use a variety of files formats and among those .stl files.

Frosted (Ultra) Detail Plastic 3D Printing Material Information - Shapeways

Cheers,

Jesper

Indeed, Shapeways is a great company that gets things done promptly and they're very competent. I recently had a small water flowform model printed in SLS (Selective Laser Sintering) by them and it came out great. Bead blasting/polishing was only $2 extra.

Hi ...

I have also mostly had very good experiences with Shapeways. Only when I ordered a very high resolution shape did the "frosted detail" print process introduce subtle relative spacing errors. However, when contacting Shapeways' customer service about it I had a very helpful reply. My preferred 3D print service.

Jesper

Indeed, Shapeways is a great company that gets things done promptly and they're very competent. I recently had a small water flowform model printed in SLS (Selective Laser Sintering) by them and it came out great. Bead blasting/polishing was only $2 extra.

I have also mostly had very good experiences with Shapeways. Only when I ordered a very high resolution shape did the "frosted detail" print process introduce subtle relative spacing errors. However, when contacting Shapeways' customer service about it I had a very helpful reply. My preferred 3D print service.

Jesper

If simple half-rounds help that much I wonder what full waveguides at each individual opening would do? Like this:

All the curves are catenary in this 3D model. Should be easy enough to get 3D printed somewhere. I did the layout work from an image, but I have a pair of older Neo3-PDR tweeters in storage that I could get accurate measurements from using calipers.

Hi,

Would you mind sharing your 3D model in a format Cura 3D can handle? I have a Neo3 project on the way and would love to try it out! 🙂

Hi,

Would you mind sharing your 3D model in a format Cura 3D can handle? I have a Neo3 project on the way and would love to try it out! 🙂

Looks like Cura 3D supports STL, 3MF and OBJ file formats, which will be no problem for me to export from Rhino.

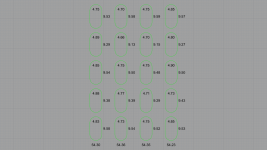

However, my current model is not accurate enough to 3D print since I merely worked on top of a picture I found:

I can pretty much guarantee that it won't line up with a real Neo3. So I'm going to head over to storage today and look for my tweeters. Then I can measure them properly with calipers and make a new model. When it's done I'll post it on my GrabCAD profile so that anyone can download it. 🙂

Attachments

Looks like Cura 3D supports STL, 3MF and OBJ file formats, which will be no problem for me to export from Rhino.

However, my current model is not accurate enough to 3D print since I merely worked on top of a picture I found:

I can pretty much guarantee that it won't line up with a real Neo3. So I'm going to head over to storage today and look for my tweeters. Then I can measure them properly with calipers and make a new model. When it's done I'll post it on my GrabCAD profile so that anyone can download it. 🙂

Sounds absolutely terrific! Thank you 🙂

How much effort is needed for the cad drawings?

Would you consider making a model fitting the neo8 aswell? If provided the measurements?

Would you consider making a model fitting the neo8 aswell? If provided the measurements?

How much effort is needed for the cad drawings?

Would you consider making a model fitting the neo8 aswell? If provided the measurements?

Doing the actual modeling ain't too bad at all. It's the taking careful measurements of every single detail that takes time. So yeah, if you provided measurements for the Neo8 I could make a model for it as well pretty quickly.

Speaking of which I finally got my Neo3 tweeters and calipers from storage today. Had to deal with automotive trouble the past few days. :/

The Neo 8 have a problem with the internal resonance, some kind of standing wave between the front and rear plates. Removing one of the removes the problem but you also reduce the output level and so´me changes at the lowest frequences.

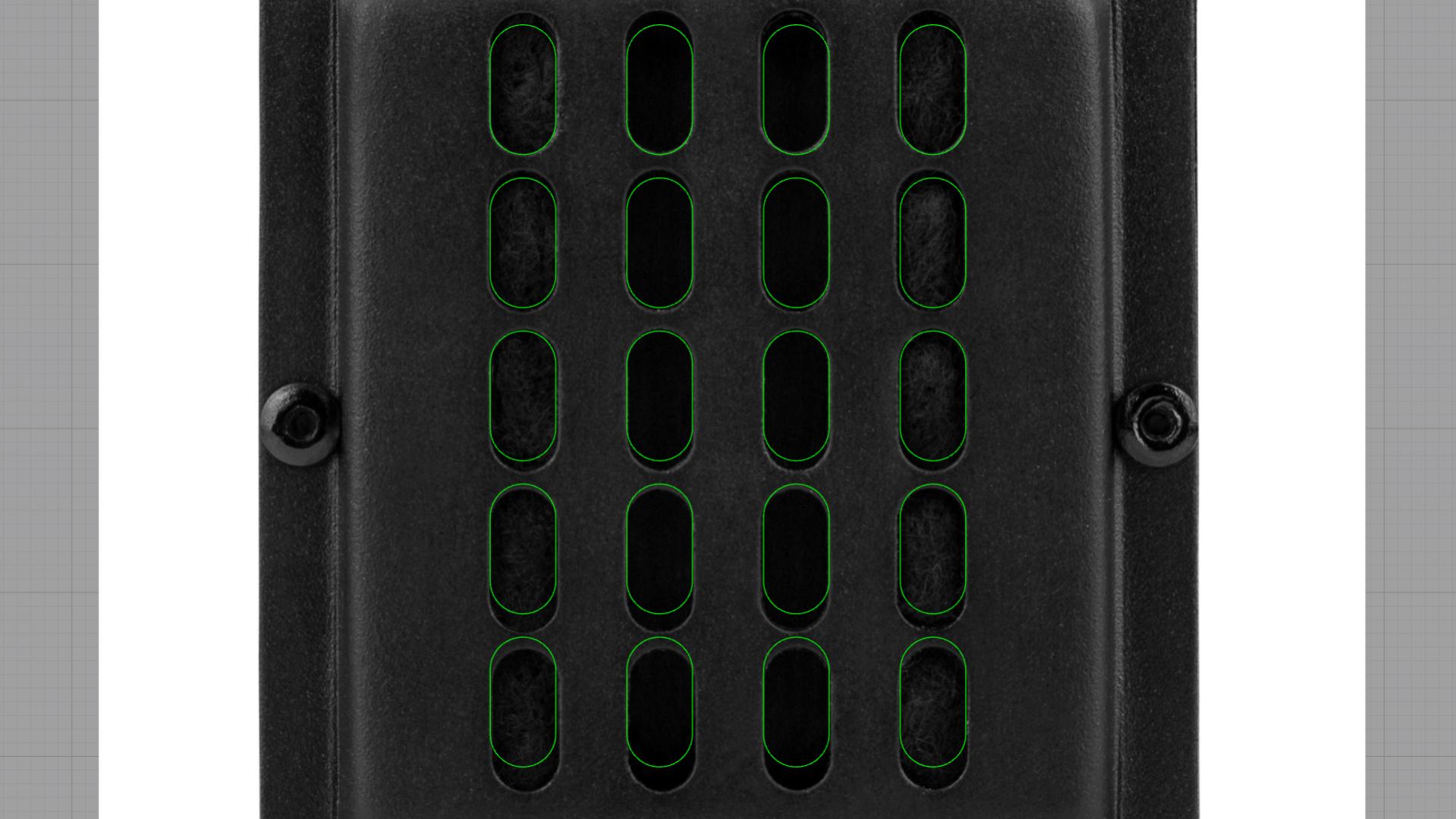

Worse yet, the windows are not in a neat grid either. They deviate substantially from where they should be centered, which is a much bigger issue. So the perfectly spaced waveguide model will never match up with the real world tweeters due to the terrible punching tolerances.

Further, when I scaled the image from Parts Express to the measured width of my tweeter I get this:

So I'm not sure if the newer tweeters have the same height for the windows? I ordered my Neo3 pair back in 2004.

Further, when I scaled the image from Parts Express to the measured width of my tweeter I get this:

So I'm not sure if the newer tweeters have the same height for the windows? I ordered my Neo3 pair back in 2004.

Attachments

When I get back home I will post two versions of the 3D model for the waveguides:

1. Version made by tracing the Parts Express image.

2. Version made using measurements of my tweeter.

1. Version made by tracing the Parts Express image.

2. Version made using measurements of my tweeter.

- Home

- Loudspeakers

- Planars & Exotics

- BG NEO 3 FR optimization