Yeah, it's a good little thread, read it twice. I wonder what Robin finally settled on?hi all it is so quiet!!!

I would have gone for something in between the SS15 and TH18, like maybe a few inch thinner TH18.

Even longer time, even less posting 😉

Hi there!

I finally settled on a version of the SS15, I optimised as much as I could for the Kappalite 3015LF drivers I had, which was not the same version of the driver that JBell designed for from the beginning.

I seem to have said that I would upload the drawings of my final version of the SS15, but I think I forgot to do that

I did cheat a bit, this design is not quite an SS15, since it uses more than a single sheet of ply, lets call it an NQSS15 or something 😛 It uses exactly one full sheet of 12mm ply, but all the internal bracing is made from a bit less than a quarter sheet of 9mm birch ply, since I had it lying around, and it was enough for building 4cabs. I only ever built 2 cabs though, but have material for building two more. Perhaps we´ll build two more, our Pine-plt T48s are starting to break after 6 years hard use, and needs to be replaced. We are building a larger system, but will need smaller subs for small gigs as well, so perhaps there´ll be 2 more SS15 with the drivers we have in our T48s, like the original plan when I did this design 🙂

The first 90% or so of the build was completed in the summer of 2013, but then reality happend, and they are still not finished, really only missing paint, grill, casters and the speakondish.

In the summer of 2014 we broke a driver in our of our T48s, so had to use one of the ones we were going to put in the first SS15s, so that hampered the build even more 😛 But, just the last few week I have picked up the build again, holes are routered for the dishes, T-nuts mounted for rubberfeet and casters, and one more driver and material for grills have been purchased, Hopefully I can find some time this weekend to start painting them with Blue Arans Tuffcab 🙂

But, I have attached the drawing and the cutsheet, and some pictures, the first ones from the build in 2013, the last one I took the other day after having testmounted the casters on the first one 🙂

As you can see, the handles are complicated, and took probably as much if not more time then the rest of the woodwork 😛 I never did a cutsheet for the 9mm ply, since I CNC-cut aluminium templates for the parts that where 9mm, and copied the templates with a router 🙂

There are CAD files if anyone would want them 🙂

//Robin

Hi there!

I finally settled on a version of the SS15, I optimised as much as I could for the Kappalite 3015LF drivers I had, which was not the same version of the driver that JBell designed for from the beginning.

I seem to have said that I would upload the drawings of my final version of the SS15, but I think I forgot to do that

I did cheat a bit, this design is not quite an SS15, since it uses more than a single sheet of ply, lets call it an NQSS15 or something 😛 It uses exactly one full sheet of 12mm ply, but all the internal bracing is made from a bit less than a quarter sheet of 9mm birch ply, since I had it lying around, and it was enough for building 4cabs. I only ever built 2 cabs though, but have material for building two more. Perhaps we´ll build two more, our Pine-plt T48s are starting to break after 6 years hard use, and needs to be replaced. We are building a larger system, but will need smaller subs for small gigs as well, so perhaps there´ll be 2 more SS15 with the drivers we have in our T48s, like the original plan when I did this design 🙂

The first 90% or so of the build was completed in the summer of 2013, but then reality happend, and they are still not finished, really only missing paint, grill, casters and the speakondish.

In the summer of 2014 we broke a driver in our of our T48s, so had to use one of the ones we were going to put in the first SS15s, so that hampered the build even more 😛 But, just the last few week I have picked up the build again, holes are routered for the dishes, T-nuts mounted for rubberfeet and casters, and one more driver and material for grills have been purchased, Hopefully I can find some time this weekend to start painting them with Blue Arans Tuffcab 🙂

But, I have attached the drawing and the cutsheet, and some pictures, the first ones from the build in 2013, the last one I took the other day after having testmounted the casters on the first one 🙂

As you can see, the handles are complicated, and took probably as much if not more time then the rest of the woodwork 😛 I never did a cutsheet for the 9mm ply, since I CNC-cut aluminium templates for the parts that where 9mm, and copied the templates with a router 🙂

There are CAD files if anyone would want them 🙂

//Robin

Attachments

-

Nzone SS15 Sideview.pdf66.5 KB · Views: 359

-

Nzone SS15 Cutsheet 12mm.pdf63.9 KB · Views: 190

-

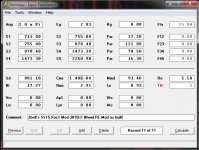

Nzone SS15 HR input.jpg95.6 KB · Views: 394

Nzone SS15 HR input.jpg95.6 KB · Views: 394 -

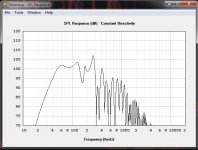

Nzone SS15 SPL Response.jpg73.7 KB · Views: 400

Nzone SS15 SPL Response.jpg73.7 KB · Views: 400 -

20130702_211222.jpg492.6 KB · Views: 405

20130702_211222.jpg492.6 KB · Views: 405 -

20130702_211231.jpg418 KB · Views: 377

20130702_211231.jpg418 KB · Views: 377 -

20130702_211247.jpg408.5 KB · Views: 375

20130702_211247.jpg408.5 KB · Views: 375 -

20131113_095417.jpg480.5 KB · Views: 240

20131113_095417.jpg480.5 KB · Views: 240 -

20131113_095428.jpg405.8 KB · Views: 251

20131113_095428.jpg405.8 KB · Views: 251 -

IMG_20160415_223257.jpg489.1 KB · Views: 240

IMG_20160415_223257.jpg489.1 KB · Views: 240

Oh wow, thanks for the update, with pics too!

Nice handle holes.

Have you ever looked into building them with marine composites instead of wood? About half the weight of ply. Typically a foam core, with fiberglass mat epoxied on, very rigid,

Nice handle holes.

Have you ever looked into building them with marine composites instead of wood? About half the weight of ply. Typically a foam core, with fiberglass mat epoxied on, very rigid,

What I mean by marine composites is this kind of stuff http://atlcomposites.com.au/icart/products/92/images/main/Duflex brochure.pdf Most countries will have a local equivalent. You can get carbon fiber skinned versions for extra stiffness too if your wallet goes deep enough.

Yeah, it's a good little thread, read it twice. I wonder what Robin finally settled on?

I would have gone for something in between the SS15 and TH18, like maybe a few inch thinner TH18.

Check out: http://www.diyaudio.com/forums/subw...rse-engineering-sim-tham15ds.html#post4445680 The PA385 spec's are now considered questionable. The 15TBX100 rocks this however.

Awesome build Robin! Very production line looking. I think the effort on the handles was worth it!

Check out: http://www.diyaudio.com/forums/subw...rse-engineering-sim-tham15ds.html#post4445680 The PA385 spec's are now considered questionable. The 15TBX100 rocks this however.

I'd love to hear if anyone's actually tried and measured a 15TBX100 in that design. It's a single sheet design (with a bit to spare) that actually gets below 50 Hz 🙂

Check out: http://www.diyaudio.com/forums/subw...rse-engineering-sim-tham15ds.html#post4445680 The PA385 spec's are now considered questionable. The 15TBX100 rocks this however.

In a nutshell, what's the difference between the THAM15DS design, and Anders Martinsson's THAM15 design? There is probably some massive thread that explains it which I haven't read yet 🙂

IMO, not much. Seems like every HR update brings the designs closer to each other but when we started with it, it definitely had a lower corner and I think that was Don's goal, to be "in between" the popular smaller and larger TH designs. That said, the DS has a flatter extended response >100hz.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- "Best" PA subdesign for the Eminence Kappalite 3015LF