Hello diyrayk and all,

Back then, air borne linear trackers like the Denneson already were around. Finnicky things, very prone to lateral oscillation, but occasionally i.e. on a perfectly centered record groove sounding quite nice.

The Rabco SL8e only was for tinkerers and DIY oriented people as it was not reliable enough and the cat whisker switch often would fail .. so the reputation was "damn this thing sounds good .. if it works at all". I never could audition one, i more than once saw one sitting on the shelf for display. The bean counter fraction would complain about the angular deviation becoming too big until the servo's 2-point regulator did something.

And then there was the Goldmund T3b which to my knowledge was inspired by the Rabco SL8e. The T3b came with a 19" rack mount unit having three knobs at the front plate. It must have been control knobs for the servo's PID regulator. The shop clerks (probably being advised by the manufacturer) never let anyone near those control knobs. The T3b was mounted on a Goldmund Studio, usually with a Koetsu Black or a Supex SD 900 or SDX1000, and particularly with the Supex, the combo sounded fantastic, best sound i heard back then.

Then there must have been someone who did change the 3 knob's settings.

The shop clerks never got the tonearm servo working again properly and as there was noone around with even basic knowledge of closed loop regulator theory, someone who may have heard about Ziegler-Nichols optimization of a PID reg loop, noone else got the gadget working again.

The outstanding rep of the T3b changed to "you never know when it stops working". The fact that adjusting arm and cartridge could take up to 4 weeks did not help, the reputation "it works outstanding if you can make it work" stuck. And in that shop, the T3b soon was replaced by a Dennesen.

Later on, Goldmund and Lurné sold the T5 which was a cheaper linear tracker. As the T5's sonics were good to average, it did not become a coveted item and was soon forgotten in the wake of servo distrust.

My point of view: Goldmund's development department outsourced the responsibility for the proper PID reg setting to the end customer. Which i consider to be equivalent to handing a sharp knife to a 3 year old infant.

After that, no manufacturer dared to sell another active linear tracker. The passive airborne linear trackers became the mainstream and today "everyone knows" that servos mess up a linear tracker's sonics and that angular deviations are growing waaaay to big until countermeasures are taken. In the last week a buddy told me that even Michael Fremer "elaborates in epic detail on angular deviation of servo-driven linear trackers".

According to what i heard from my buddy about Fremer, he seems to grossly exaggerate sonic impact of angular deviation. Can it be that Fremer made those experiences with a T3b and did not realize that his control unit's knob settings were wrong? That would indicate that Fremer does not know waht he is talking about.

TMK, Fremer does not tinker with DIY stuff. So it must have been a Goldmund T3b or T3f as these were the last servo-driven linear trackers commercially available.

For me the same. Pivoted arm hassle: gone! As you said above, the arm makes the cartride sail thru difficult passages effortlessly, with a spinnaker sail, so to speak.

I use my Rabco as i got it from David Shreve; he did what he thought was necessary. The original 2-point reg remained. And i was surprised how much angular deviation had to build up until it became clearly audible. Of course, pace rhythm and timing would suffer slightly, ever so slightly, as due to "offset angle" building up, left and right channel were no longer perfectly in sync. But then, not all listeners are highly perceptive AFA PRaT is concerned, so that effect might not weigh much.

Bottom line: one can live well and happy with more lateral angular deviation than you might think , say, 0.3° to either side before anything becomes audible. Maybe more.

I do not know what David did to the cat whisker switch to make it reliable, but it worked. Maybe he goldplated it?

For my own design, i have a high-resolution angular sensor feeding an analogue voltage into a PID regulator loop. The arm will be able to run backwards on excentric records which is a thing the Rabco does not do. The Rabco runs forward only which makes things easy with off-center records.

Biggest challenge is to find a servo motor which covers the needed ratio between lowest and highest speed needed: slowest average speed for an LP is 40µm/sec and the maximum speed of an 78rpm excentric leadout groove with 12mm excentricity is 48.5mm/sec. Currently, i do not see anything but a stepper motor 🙁 suitable to cover that low speed and speed range. Who knows, i may have to employ microstepping to smoothen out the edges ...

maybe i should tell how i experienced the linear tracker story and how the anti-servo sentiment developped:[...]

True 'linear' trackers can be passive mechanical/air bearing, or active (servo-driven). I've seen a lot of anti-servo sentiment displayed on several audio websites. I've encountered blowback after posting key points in favor of servo linear trackers. Most readers automatically assumed I was talking about passive designs. I don't understand the anti-servo sentiment, because I have found that making an active servo function properly is FAR easier than dealing with anti-skating issues.

Back then, air borne linear trackers like the Denneson already were around. Finnicky things, very prone to lateral oscillation, but occasionally i.e. on a perfectly centered record groove sounding quite nice.

The Rabco SL8e only was for tinkerers and DIY oriented people as it was not reliable enough and the cat whisker switch often would fail .. so the reputation was "damn this thing sounds good .. if it works at all". I never could audition one, i more than once saw one sitting on the shelf for display. The bean counter fraction would complain about the angular deviation becoming too big until the servo's 2-point regulator did something.

And then there was the Goldmund T3b which to my knowledge was inspired by the Rabco SL8e. The T3b came with a 19" rack mount unit having three knobs at the front plate. It must have been control knobs for the servo's PID regulator. The shop clerks (probably being advised by the manufacturer) never let anyone near those control knobs. The T3b was mounted on a Goldmund Studio, usually with a Koetsu Black or a Supex SD 900 or SDX1000, and particularly with the Supex, the combo sounded fantastic, best sound i heard back then.

Then there must have been someone who did change the 3 knob's settings.

The shop clerks never got the tonearm servo working again properly and as there was noone around with even basic knowledge of closed loop regulator theory, someone who may have heard about Ziegler-Nichols optimization of a PID reg loop, noone else got the gadget working again.

The outstanding rep of the T3b changed to "you never know when it stops working". The fact that adjusting arm and cartridge could take up to 4 weeks did not help, the reputation "it works outstanding if you can make it work" stuck. And in that shop, the T3b soon was replaced by a Dennesen.

Later on, Goldmund and Lurné sold the T5 which was a cheaper linear tracker. As the T5's sonics were good to average, it did not become a coveted item and was soon forgotten in the wake of servo distrust.

My point of view: Goldmund's development department outsourced the responsibility for the proper PID reg setting to the end customer. Which i consider to be equivalent to handing a sharp knife to a 3 year old infant.

After that, no manufacturer dared to sell another active linear tracker. The passive airborne linear trackers became the mainstream and today "everyone knows" that servos mess up a linear tracker's sonics and that angular deviations are growing waaaay to big until countermeasures are taken. In the last week a buddy told me that even Michael Fremer "elaborates in epic detail on angular deviation of servo-driven linear trackers".

According to what i heard from my buddy about Fremer, he seems to grossly exaggerate sonic impact of angular deviation. Can it be that Fremer made those experiences with a T3b and did not realize that his control unit's knob settings were wrong? That would indicate that Fremer does not know waht he is talking about.

TMK, Fremer does not tinker with DIY stuff. So it must have been a Goldmund T3b or T3f as these were the last servo-driven linear trackers commercially available.

My original SL8E mod has undergone 2 significant improvements in the intervening years. First, it now has a 2 stage cueing linkage that limits the cueing height to about 1/4 inch. Second, and most beneficial, an optoelectronic circuit that drives the carriage motor continuously in a variable speed mode, eliminating the troublesome OEM cat whisker contact on/off control. I have enjoyed using my modified arm for all these years as I read post after post of user frustrations with anti-skate settings, Lofgren/Baerwald/Beethoven alignment wars, sticky bearings, noisy air pumps, and causes of end-of-record IGD.

[...]

For me the same. Pivoted arm hassle: gone! As you said above, the arm makes the cartride sail thru difficult passages effortlessly, with a spinnaker sail, so to speak.

I use my Rabco as i got it from David Shreve; he did what he thought was necessary. The original 2-point reg remained. And i was surprised how much angular deviation had to build up until it became clearly audible. Of course, pace rhythm and timing would suffer slightly, ever so slightly, as due to "offset angle" building up, left and right channel were no longer perfectly in sync. But then, not all listeners are highly perceptive AFA PRaT is concerned, so that effect might not weigh much.

Bottom line: one can live well and happy with more lateral angular deviation than you might think , say, 0.3° to either side before anything becomes audible. Maybe more.

I do not know what David did to the cat whisker switch to make it reliable, but it worked. Maybe he goldplated it?

For my own design, i have a high-resolution angular sensor feeding an analogue voltage into a PID regulator loop. The arm will be able to run backwards on excentric records which is a thing the Rabco does not do. The Rabco runs forward only which makes things easy with off-center records.

Biggest challenge is to find a servo motor which covers the needed ratio between lowest and highest speed needed: slowest average speed for an LP is 40µm/sec and the maximum speed of an 78rpm excentric leadout groove with 12mm excentricity is 48.5mm/sec. Currently, i do not see anything but a stepper motor 🙁 suitable to cover that low speed and speed range. Who knows, i may have to employ microstepping to smoothen out the edges ...

I just bought a Rabco SL-8E off ebay [...]

I tried it tonight after a few minutes still powers up raises and lowers and appears to track slowly in one direction down the chain/ track. Needs to be serviced. I don't have a cartridge to test it fully.

Hello super10018,

looks like your Rabco works as promised. Behaves like mine. Get yourself a cheap cartridge and maybe a surplus directdrive TT and test it.

The Rabco is a good base to get yourself a world-class linear tracker, even without improving the servo mechanism.

IMO, David's most important changes were:

- tonearm wand solid and made from two different woods

- new gymbal with close to zero bearing friction/torque

- put damping putty on any flat metal surface to prevent ringing

- get the cat whisker contacts reliable

I won't tell all of David's secrets here, it is his IP after all.

What i intend to do to my Rabco: equip it with means for a decent VTA and rail's horizontal slope adjustment. Moreover, i have to make it compatible to my current linear tracker's base unit so that i can swap my linear tracker with David's Rabco and compare them both. My base unit provides a hinge axis which can be adjusted to be exactly colinear with the operating straight (the geometric locus, the linear tracker's stylus path). As soon as the base unit's height and slope is right, the arm's VTA will not change over the full excursion of 135mm (by more than 10 arc seconds); the upper side of the hinge structure (to which the linear tracker's rail is mounted) then can rotate around the hinge axis to provide VTA changes - without messing up "overhang". And as i hate adjustment screws to have a pitch too coarse, i use differential screws for both VTA and rail slope adjustment.

dice45,

What do you think of Analogue Audio Association? Analogue Audio Association - Home

Is this a great place to discuss everything vinyl and analogue?

What do you think of Analogue Audio Association? Analogue Audio Association - Home

Is this a great place to discuss everything vinyl and analogue?

dice45,

What do you think of Analogue Audio Association? Analogue Audio Association - Home

Is this a great place to discuss everything vinyl and analogue?

no comment without my lawyer being present ... let us talk audio content

no comment without my lawyer being present ... let us talk audio contentBernhard, thanks for your reply and suggestions!

I am still waiting the arm now. Once I get it, I will try to test it first and get basic idea how it works. In the meantime, I am working on my 2nd air bearing arm now.

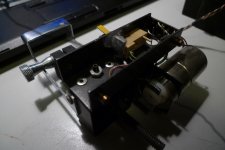

Here are some photos from the seller. It looks in decent condition.

I am still waiting the arm now. Once I get it, I will try to test it first and get basic idea how it works. In the meantime, I am working on my 2nd air bearing arm now.

Here are some photos from the seller. It looks in decent condition.

Attachments

Hello Bernhard

In the mid 1970s I had the chance to take a close look at a Goldmund tangentially tracking tone arm. Amongst other things, I noticed a high speed, geared down motor to drive the carriage. The motor was made by Portescap in Switzerland. It didn't make sense to use a fast running motor, only to gear it down to achieve the slow speed needed to drive the carriage of a tone arm, and so I decided that, in the future, I would use a stepping motor which would only turn as fast as needed.

Then, in the early 1980s, I received a US Patent on the use of a stepper motor in a servo controlled tone arm. I controlled the "shocks" produced by the stepper, by coupling it to the carriage through an O-ring. I devised a digital display so that I could observe the exact moment when the motor stepped, while listening to a steady state test tone from a test record. there was absolutely no audible variation of the pitch of the test tone.

The patent has long since expired. 🙁

Sincerely.

Ralf

Currently, i do not see anything but a stepper motor 🙁 suitable to cover that low speed and speed range. Who knows, i may have to employ microstepping to smoothen out the edges ...

In the mid 1970s I had the chance to take a close look at a Goldmund tangentially tracking tone arm. Amongst other things, I noticed a high speed, geared down motor to drive the carriage. The motor was made by Portescap in Switzerland. It didn't make sense to use a fast running motor, only to gear it down to achieve the slow speed needed to drive the carriage of a tone arm, and so I decided that, in the future, I would use a stepping motor which would only turn as fast as needed.

Then, in the early 1980s, I received a US Patent on the use of a stepper motor in a servo controlled tone arm. I controlled the "shocks" produced by the stepper, by coupling it to the carriage through an O-ring. I devised a digital display so that I could observe the exact moment when the motor stepped, while listening to a steady state test tone from a test record. there was absolutely no audible variation of the pitch of the test tone.

The patent has long since expired. 🙁

Sincerely.

Ralf

Last edited:

Hi,

seeing the pics and reading about the Rabco and Goldmund I wonder what made them so special -and costly- against all those other ´active´ linear trackers?

Most japanese LTs used optical sensors, apart from Sony, who also used magnetic sensors (electromagnetic dampers at the same, a system named Biotracer).

Technics, Sony, Yamaha, Pioneer, Mitsubishi and others used a belt, a wire or a string driven by a (geared) servo motor for forward-back motion.

Seems Pioneer went a step further in their PL-L800 and PL-L1000 where they utilized a linear motor to direct drive the arm carriage.

Looks alot more refined, compact (and reliable?) and looks and finish seem way above the Rabco and Goldmund.

jauu

Calvin

seeing the pics and reading about the Rabco and Goldmund I wonder what made them so special -and costly- against all those other ´active´ linear trackers?

Most japanese LTs used optical sensors, apart from Sony, who also used magnetic sensors (electromagnetic dampers at the same, a system named Biotracer).

Technics, Sony, Yamaha, Pioneer, Mitsubishi and others used a belt, a wire or a string driven by a (geared) servo motor for forward-back motion.

Seems Pioneer went a step further in their PL-L800 and PL-L1000 where they utilized a linear motor to direct drive the arm carriage.

Looks alot more refined, compact (and reliable?) and looks and finish seem way above the Rabco and Goldmund.

jauu

Calvin

Hello Calvin and all,

1.) Goldmund was intended as a highend product. Was meant to be the best tonearm in the world. Noone takes a worldclass product serios if it does not cost enough. And Goldmund wanted to exploit that.

2.) For any manufacturer of small-batch audio gear, the ratio of end customer selling price to manufacturing cost has to be higher than 4, otherwise he is not earning money. And this is not taking into account that many customers expect large discounts.

3.) The Rabco was never expensive, in its days. Someone else posted that the original street price was US$ 169.- back then, that would be around 1000 $ today.

Look at the build quality on the pixes: it is built as cheap as possible (possibly cheaper). It just works very well (... if it works at all).

And, please, don't confuse the standard Rabco with David Shreve's rebuild. Sonically, it is a different class. I had the opportunity to compare both. With the standard Rabco, the sonic footprint of a well-working servo-driven linear tracker is clearly audible yet due to the cheapocheapo sheet metal construction, it is tonally not the most pleasing thing, you could say, it rings like a group of bells.

David's re-build sounds completely harmonic, musical, dynamic, effortless, undistorted, breathing treble. However, it looks almost as crappy as the standard Rabco, who would agree to spend serious money on that ?!

Not every engineering effort pays, sonically at least. I would not have my delicate unshielded tonearm wiring exposed to a linear motor's magnetic stray fields.

It should be considered that the mentioned designs were meant for large production numbers. under such circumstances, higher engineering effort is economically justifiable.

BTW, Goldmund used an optical sensor and a closed loop position control with PID regulator.

For my current linear tracker design, i also use an optical sensor, with very high resolution, i might add. Just, my sensor is very hidden too, it does not use separate sensor arms like the Goldmund and some of the designs you mentioned (every freely protruding arm/beam is the half of a tuning fork, after all ... and resonates at its own base frequency with just the same enthusiasm).

For driving the carriage i use a miniature timing belt driven by a stepper motor (with some torque-shock-absorber coupling in between).

seeing the pics and reading about the Rabco and Goldmund I wonder what made them so special -and costly- against all those other ´active´ linear trackers?

1.) Goldmund was intended as a highend product. Was meant to be the best tonearm in the world. Noone takes a worldclass product serios if it does not cost enough. And Goldmund wanted to exploit that.

2.) For any manufacturer of small-batch audio gear, the ratio of end customer selling price to manufacturing cost has to be higher than 4, otherwise he is not earning money. And this is not taking into account that many customers expect large discounts.

3.) The Rabco was never expensive, in its days. Someone else posted that the original street price was US$ 169.- back then, that would be around 1000 $ today.

Look at the build quality on the pixes: it is built as cheap as possible (possibly cheaper). It just works very well (... if it works at all).

And, please, don't confuse the standard Rabco with David Shreve's rebuild. Sonically, it is a different class. I had the opportunity to compare both. With the standard Rabco, the sonic footprint of a well-working servo-driven linear tracker is clearly audible yet due to the cheapocheapo sheet metal construction, it is tonally not the most pleasing thing, you could say, it rings like a group of bells.

David's re-build sounds completely harmonic, musical, dynamic, effortless, undistorted, breathing treble. However, it looks almost as crappy as the standard Rabco, who would agree to spend serious money on that ?!

Most japanese LTs used optical sensors, apart from Sony, who also used magnetic sensors (electromagnetic dampers at the same, a system named Biotracer).

Technics, Sony, Yamaha, Pioneer, Mitsubishi and others used a belt, a wire or a string driven by a (geared) servo motor for forward-back motion.

Seems Pioneer went a step further in their PL-L800 and PL-L1000 where they utilized a linear motor to direct drive the arm carriage.

Looks a lot more refined, compact (and reliable?) and looks and finish seem way above the Rabco and Goldmund

Not every engineering effort pays, sonically at least. I would not have my delicate unshielded tonearm wiring exposed to a linear motor's magnetic stray fields.

It should be considered that the mentioned designs were meant for large production numbers. under such circumstances, higher engineering effort is economically justifiable.

BTW, Goldmund used an optical sensor and a closed loop position control with PID regulator.

For my current linear tracker design, i also use an optical sensor, with very high resolution, i might add. Just, my sensor is very hidden too, it does not use separate sensor arms like the Goldmund and some of the designs you mentioned (every freely protruding arm/beam is the half of a tuning fork, after all ... and resonates at its own base frequency with just the same enthusiasm).

For driving the carriage i use a miniature timing belt driven by a stepper motor (with some torque-shock-absorber coupling in between).

In the mid 1970s I had the chance to take a close look at a Goldmund tangentially tracking tone arm. Amongst other things, I noticed a high speed, geared down motor to drive the carriage. The motor was made by Portescap in Switzerland. It didn't make sense to use a fast running motor, only to gear it down to achieve the slow speed needed to drive the carriage of a tone arm, and so I decided that, in the future, I would use a stepping motor which would only turn as fast as needed.

Then, in the early 1980s, I received a US Patent on the use of a stepper motor in a servo controlled tone arm. I controlled the "shocks" produced by the stepper, by coupling it to the carriage through an O-ring. I devised a digital display so that I could observe the exact moment when the motor stepped, while listening to a steady state test tone from a test record. there was absolutely no audible variation of the pitch of the test tone.

The patent has long since expired. 🙁

Hello Ralf,

thank you very much for your input. Something similar went thru my mind and to learn that it works helps me a lot.

What i learned from a stepper motor expert is that with µstepping, one does not loose torque at ... all and the steps are not only smaller, they are smoother, too. As i need to gear the stepper down a bit, it will be a combination of O-ring and µstepping for me.

Please consider: the excursion range of a classic linear tracker is about 110 to 135 mm whereas your design needs an excursion of 30-35 mm? so the steps distribute on that smaller distance. Should make the steps smaller.

Seems Pioneer went a step further in their PL-L800 and PL-L1000 where they utilized a linear motor to direct drive the arm carriage.

Looks alot more refined, compact (and reliable?) and looks and finish seem way above the Rabco and Goldmund.

I owned a few Pioneer PL-L1000's before and they were prone to over gliding back and forth and would shoot out of range. Perhaps mine were not tweaked right. On some off centered records they tend to go berserk. Sometimes the maglev glid lags behind. I don't think a servo arm needs to go bidirectional unless you plan to play a lot of eccentric records. No, I wouldn't say they're reliable. I much prefer the Yamaha PX-3 (or Rabco) concept of gliding only forward direction. I do agree there are many sleepers in Japanese linear turntables. Another nice one is Technics SL-M3, except the arm only takes P-mount cartridges.

Hello direct driver,

Did some statistics back when i was knee-deep into airborne linear tracker design: approx.1/3 of my records are eccentric. Many of them show different excentricity on either side.

For my design, i plan to have 6 different detector circuits for the automatic lift. Mostly analogue computing circuitry. some of those circuits are fed from the angular sensor's raw voltage, some from the PID reg's output. The mentioned low pass might make most of those circuits useless. But, who knows where i end up.

will work only if the servo loop has a pronounced low pass characteristic, blending out groove pattern excentricity. This is the case with the Rabco's 2-point regulator servo loop.[...] I don't think a servo arm needs to go bidirectional unless you plan to play a lot of eccentric records. [...]

Did some statistics back when i was knee-deep into airborne linear tracker design: approx.1/3 of my records are eccentric. Many of them show different excentricity on either side.

For my design, i plan to have 6 different detector circuits for the automatic lift. Mostly analogue computing circuitry. some of those circuits are fed from the angular sensor's raw voltage, some from the PID reg's output. The mentioned low pass might make most of those circuits useless. But, who knows where i end up.

But, who knows where i end up.

That's the fun part! 🙂

I admire your work. Let it be known I'm not against servo arms at all, even though I started a couple threads on tangential pivot arms and non-servo non-airbearing mechanical arms. I appreciate tonearms of all genres. I owned couple Rabcos before but due to bad bearings I sold them off. However, I did appreciate the idea and ingenuity of it. I think a servo armbase on linear glide with conventional pivot arm has potential and is more adaptive, provided the headshell offset angle needs to be straightened. As Conrad Hoffman once pointed out in a post that pivot arm design have reached maturity and there's no need to reinvent the wheel and if we can just mount one on a horizontal base with sevo... I look forward to learning more about servo arm designs.

Hi

I don't know much about linear tracking arms but I do have an almost new ET2 which I've never had the 'courage' to fit to one of my Garrard 301's. Don't ask me why as they seem to have a good reputation.

Some years ago, a customer brought me his VPI HW19? with one of these ET arms fitted. With the turntable, he also supplied 3 dead wands which I had to repair.

My own ET2 also has several wands but they are fine.

I have played quite a bit with linear arms as fitted to B&O - eg models 4000 and 4002's. Do you have any comment (with or without your lawyer's presence😀) on B&O's 70's design?

Regds

bulgin

I don't know much about linear tracking arms but I do have an almost new ET2 which I've never had the 'courage' to fit to one of my Garrard 301's. Don't ask me why as they seem to have a good reputation.

Some years ago, a customer brought me his VPI HW19? with one of these ET arms fitted. With the turntable, he also supplied 3 dead wands which I had to repair.

My own ET2 also has several wands but they are fine.

I have played quite a bit with linear arms as fitted to B&O - eg models 4000 and 4002's. Do you have any comment (with or without your lawyer's presence😀) on B&O's 70's design?

Regds

bulgin

I have played quite a bit with linear arms as fitted to B&O - eg models 4000 and 4002's. Do you have any comment (with or without your lawyer's presence😀) on B&O's 70's design?

Hello bulgin,

sorry, no experience with the B&O models. However, I have heard a buddy report that a B&O linear tracker together with an original B&O cartridge works amazingly well.

ET2:

be warned, an ET2 is a cartridge eater unless it it perfectly level. The ET2's pivotal VTA adjustment (patented) has my admiration (

to Bruce Thipgen), but its mounting base is waaay to small and sports 3 tiny needle-sharp tippy-toe set screws to adjust the bearing tube's orientation and horizontal slope. Those set screws dig for potatoes and it is a punishment for the god-less to get the bearing tube properly aligned. And this is the reason why i never bought an ET2, not even 2nd hand.

to Bruce Thipgen), but its mounting base is waaay to small and sports 3 tiny needle-sharp tippy-toe set screws to adjust the bearing tube's orientation and horizontal slope. Those set screws dig for potatoes and it is a punishment for the god-less to get the bearing tube properly aligned. And this is the reason why i never bought an ET2, not even 2nd hand.That's the fun part! 🙂

I admire your work. Let it be known I'm not against servo arms at all, even though I started a couple threads on tangential pivot arms and non-servo non-airbearing mechanical arms. I appreciate tonearms of all genres. I owned couple Rabcos before but due to bad bearings I sold them off. However, I did appreciate the idea and ingenuity of it. I think a servo armbase on linear glide with conventional pivot arm has potential and is more adaptive, provided the headshell offset angle needs to be straightened. As Conrad Hoffman once pointed out in a post that pivot arm design have reached maturity and there's no need to reinvent the wheel and if we can just mount one on a horizontal base with servo... I look forward to learning more about servo arm designs.

Hello directdriver

being for / against something clouds the mind, obscures concepts, impedes understanding.

So i try not to favor/disfavor. I want to remain able to appreciate advantages of a concept despite the fact that i abandoned it as a whole ... and i want no ideology keeping me from using the concept (or parts of it) in another context later. Moreover, i have learned that the experiment always wins, and if a neat theory contradicts the experiment's outcome, too bad for the theory/ideology. An experiment can reveal, for instance, that theory is valid, but has no significance. Particularly in Audio!

I also do not want to take the fun away for people who invested a lot of money, time, effort and emotion to get something working at all and be happy with that success. I do not want to rub it in that the (supposedly complete) success is only partial. That is why i have read those threads quite thoroughly but did not post.

Rabco:

the original Rabco's bearing seem to get lost or damaged easily, it is a well-known problem.

In general, the Rabco violates the 2nd Einsteinian rule: design everything as simple as possible, but not simpler !! ... the Rabco is too simple in several aspects.

The original Rabco has exchangeable tonearm wands, but the gymbal itself is not suited to exchange whole tonearm wand / counterweight assemblies. So, goodby to quick and easy swapping of cartridges. And the massive clamping is prone to damage the bearings. Oh, and the wand itself is ringy and the carriage wheels are rattling.

Look how the cartridge swapping business was solved on the Micro Seiki Max282: the whole arm assembly had a smartly designed interface to the inner gymbal: one knurled ring screwed loose and the whole arm assembly with counterweight could be lifted off the gymbal. Every adjustment (except VTA ) came with the arm assembly and swapping cartridges was done in a minute without loosing sonic performance.

And that is what i try to achieve with my current linear tracker design: the servo-driven carriage contains the gymbal and there is a simple and free-of-play interface between arm assembly and gymbal. And so i need one linear tonearm only for all the records i want to play. i simply put my arm assembly on my gymbal like i would put a toy locomotive on its rail. And play music --- instead of fuzzing around with adjustments.

I received the Rabco arm and did some tests.

Both motors are running fine. But it is on and off randomly. I think it is caused by bad contacts of switches. And the carriage doesn’t move even if the motor was running and the bead chain was moving.

I checked sound fountain web site and service manual. Both state that the carriage is clamped to the bead chain via a rubber pad. Obviously, my arm is missing the rubber pad. But I am not sure how the rubber pad is clamped on the carriage. What kind of rubber pad is it? What is the dimensions of the rubber pad? Does the rubber pad push up against the bridge to move the carriage?

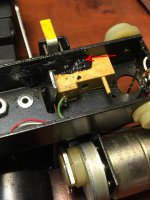

It seems to me that the previous owner tried to glue the rubber pad. Please see attached image.

Both motors are running fine. But it is on and off randomly. I think it is caused by bad contacts of switches. And the carriage doesn’t move even if the motor was running and the bead chain was moving.

I checked sound fountain web site and service manual. Both state that the carriage is clamped to the bead chain via a rubber pad. Obviously, my arm is missing the rubber pad. But I am not sure how the rubber pad is clamped on the carriage. What kind of rubber pad is it? What is the dimensions of the rubber pad? Does the rubber pad push up against the bridge to move the carriage?

It seems to me that the previous owner tried to glue the rubber pad. Please see attached image.

Attachments

Last edited:

I checked sound fountain web site and service manual. Both state that the carriage is clamped to the bead chain via a rubber pad. Obviously, my arm is missing the rubber pad. But I am not sure how the rubber pad is clamped on the carriage. What kind of rubber pad is it? What is the dimensions of the rubber pad? Does the rubber pad push up against the bridge to move the carriage?

It seems to me that the previous owner tried to glue the rubber pad. Please see attached image.

Hello super10018,

make sure the cat whisker contacts are free of corrosion and/or contamination (gunk, grease, dirt etc.) and maybe you want to have them gold-plated (there are gold plating pens with a small battery inside available)

Clamp:

On your pix, the elastic caulking on the clamping jaw seems to be missing.

See attached pixes of an original Rabco carriage; 1st two pixes are with jaw closed, 2nd two are with jaw open, the jaw being a part of the lift brindge protruding thru a hole of the carriage.

Both the U-shaped carriage and the clamp are thickly coated with some rubbery/silicone caulking putty (opaquely transparent in my case) where the bead chain is meant to be clamped between two rubbery surfaces. Usual bathroom caulking should do. Hope this helps.

Attachments

Hi Bernhard,

Thanks for reply!

I understand it now. But I am wondering how effect the silicone is. The silicone is soft and flexible. It may effectively reduce the vibrations of motor, but it may not do good job to move the carriage.

Thanks for reply!

I understand it now. But I am wondering how effect the silicone is. The silicone is soft and flexible. It may effectively reduce the vibrations of motor, but it may not do good job to move the carriage.

[...] but it may not do good job to move the carriage.

hello super10018,

that is exactly what it does: move the carriage.

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- Bernhard Kistner dice45 LT-1 tonearm