I am building an established design but for aesthetic reasons only, I want to put a 3/4" radius on the vertical edges of the baffle. Will this affect the sound in any way? The design fits my requirements perfectly so I don't want to spoil it. Simple language only please. I am a mere mortal and don't take easily to numbers or design software.

It is a decent sized radius so should not be a major issue sound wise.

Can the cabinet handle it without lessening its mechanical properties and its rigidity.

Which design is it, do you care to share?

Can the cabinet handle it without lessening its mechanical properties and its rigidity.

Which design is it, do you care to share?

It is a decent sized radius so should not be a major issue sound wise.

Can the cabinet handle it without lessening its mechanical properties and its rigidity.

Which design is it, do you care to share?

The design is Paul Carmody's Tarkus. I will be making the whole thing extra thick while maintaining the correct internal volume. Boxes will be at least an inch thick and the baffle will be 1.25 inch to achieve plenty of structural goodness after the radius. I'm using a lamination of plywood and MDF to get the final thicknesses.

I agree. For example, if you start with a 9" wide baffle and apply a 3/4" roundover, the baffle width is still 9" and not 7.5". If the OP wants to use thicker material than what is prescribed while maintaining the internal volume, he needs to use the same baffle dimensions and layout, so he need to maintain also the original height and width of the box, and extend the depth of the box accordingly. This is definitely true for the upper box of the tarkus, for the lower box it's not so important.

Ralf

Ralf

Excellent.

Your going to need to wear a mask, and have a dust extractor when you do that.

I replied yesterday but my post disappeared so I repeat. Yes, I understand the risks and will take appropriate precautions. MDF is nasty stuff.

I agree. For example, if you start with a 9" wide baffle and apply a 3/4" roundover, the baffle width is still 9" and not 7.5". If the OP wants to use thicker material than what is prescribed while maintaining the internal volume, he needs to use the same baffle dimensions and layout, so he need to maintain also the original height and width of the box, and extend the depth of the box accordingly. This is definitely true for the upper box of the tarkus, for the lower box it's not so important.

Ralf

You had me on board until the last part where you say I need to extend the depth of the box. Why? I will be maintaining the exact internal measurements and assumed that would keep the design volume unaltered. Any thickness I add to the structure will be external so will only add to structural rigidity. External dimensions shouldn't be an issue, or should they?

External dimensions are an issue, the front baffle needs to be pretty close to the design width. The width of the baffle determines at what frequency baffle step occurs and since this is dealt with in the crossover design the crossover must be changed if the front baffle width is changed.

IOW you'll need to make your cabinet deeper and/or taller to maintain internal volume.

IOW you'll need to make your cabinet deeper and/or taller to maintain internal volume.

You really missed my entire post, not only the last part. You don't want to change the width and height of the box, irrespective of doing a roundover or not.You had me on board until the last part where you say I need to extend the depth of the box.

The problem here is that you want to use thicker material, so you need to keep 2 external dimensions of the box unchanged, and this means you need to modify the last external dimension in order to keep the desired internal volume. For the upper tarkus box, the external dimensions are 9" width, 13.25" height and 11" depth, and with the "correct" thickness of 3/4", the internal dimensions are 7.5"Wx11.75Hx9.5D (837 cubic inches volume). If you change thickness to say 1" material, in order to keep the internal volume you need to have D=837/7/11.25=10.6" (where 7" is the new internal width and 11.25" is the new internal height, change accordingly if you use different thickness). If you give us the final thickness we will be able to do the math for you, but keep in mind that a difference of 0.5L for a 13L sealed box for mid duties isn't something to worry about.

Ralf

As others have said, do not change the baffle dimensions. Only increase the depth of the cabinet to allow for the thicker material you are going to use.

In case you don't know, the baffle is the front of the enclosure where the drivers are fitted.

In case you don't know, the baffle is the front of the enclosure where the drivers are fitted.

my experience is that a roundover edge acts differently than what is described above. If a hard-edged baffle is 9 x 13.25, and a 1 inch radius roundover is applied to the sides and top edge, the resulting baffle is 7 x 12.25. It is the flat un-cut area of the baffle that determines its baffle-step-gain, not the outer box dimensions. The roundover has the effect of smoothing out the high frequency ripples, but the baffle step is most closely approximated by the flat un-cut area of the baffle.

In practice, the difference in baffle step gain between a slightly larger and slightly smaller baffle will be small enough to be ignored. The normal tolerance variations among drivers, capacitors, and inductors will overwhelm this small difference in baffle step gain.

In practice, the difference in baffle step gain between a slightly larger and slightly smaller baffle will be small enough to be ignored. The normal tolerance variations among drivers, capacitors, and inductors will overwhelm this small difference in baffle step gain.

It doesn't work that way. You are stating as a fact what is only your idea of how diffraction works.

Read what jReave answered to your question (beveled and roundover work on the same principle): Predicting beveled cabinet difraction with "Edge" - maybe?

A roundover will only smooth the diffraction effect, but the base effect is based on the outer baffle dimensions.

Ralf

Read what jReave answered to your question (beveled and roundover work on the same principle): Predicting beveled cabinet difraction with "Edge" - maybe?

A roundover will only smooth the diffraction effect, but the base effect is based on the outer baffle dimensions.

Ralf

I was about to draw a line under this topic as one more question where I just haven't the brain cells to understand the answer. I began writing a detailed explanation etc. but toward the end there was a blinding flash of light and I suddenly grasped what you are trying to tell me. I not only have to maintain the designed internal volume but the external dimensions of the baffle as well. The extra thickness of any panels needs to be compensated for, and depth of the box is the logical place to make the adjustment. Is that it?

I have a feeling I won't be making the panels any thicker. Too easy to mess up what is supposed to be a great design.

I have a feeling I won't be making the panels any thicker. Too easy to mess up what is supposed to be a great design.

I was about to draw a line under this topic as one more question where I just haven't the brain cells to understand the answer. I began writing a detailed explanation etc. but toward the end there was a blinding flash of light and I suddenly grasped what you are trying to tell me. I not only have to maintain the designed internal volume but the external dimensions of the baffle as well. The extra thickness of any panels needs to be compensated for, and depth of the box is the logical place to make the adjustment. Is that it?

Yes.

My god everybody. Look at the Tarkus page. There have been numerous successful builds that do not follow the external dimensions exactly. With Paul Carmody's blessing.

I think it was Paul himself who said that a 10% alteration in baffle dimensions is acceptable. So let's take a look:

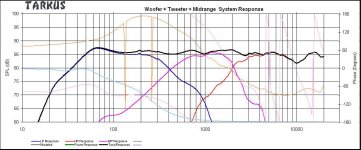

Pic 1: Tarkus FR

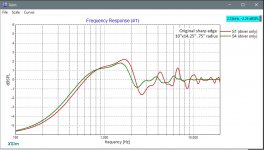

Pic 2: Tweeter Diffraction - red is the 9"x13.25" baffle with no edge treatment

- green is on a 10"x14.25" baffle with 3/4" radius and the drivers the same distances from the top edge as the original

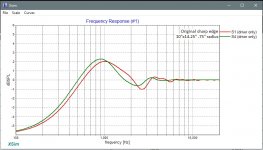

Pic 3: Mid Diffraction - red is the 9"x13.25" baffle with no edge treatment

- green is on a 10"x14.25" baffle with 3/4" radius and the drivers the same distances from the top edge as the original

In either case, I don't think there is much more than a 1dB of difference at any frequency. And the edge treatment smooths out both drivers' responses which is usually a good thing. The Tarkus FR is attached so that if you want to, you can make frequency by frequency comparisons of what the changes in diffraction will do to the overall FR.

Bottom line: a small change in baffle dimensions while including a 3/4" edge radius will be fine. Maybe even better.

I think it was Paul himself who said that a 10% alteration in baffle dimensions is acceptable. So let's take a look:

Pic 1: Tarkus FR

Pic 2: Tweeter Diffraction - red is the 9"x13.25" baffle with no edge treatment

- green is on a 10"x14.25" baffle with 3/4" radius and the drivers the same distances from the top edge as the original

Pic 3: Mid Diffraction - red is the 9"x13.25" baffle with no edge treatment

- green is on a 10"x14.25" baffle with 3/4" radius and the drivers the same distances from the top edge as the original

In either case, I don't think there is much more than a 1dB of difference at any frequency. And the edge treatment smooths out both drivers' responses which is usually a good thing. The Tarkus FR is attached so that if you want to, you can make frequency by frequency comparisons of what the changes in diffraction will do to the overall FR.

Bottom line: a small change in baffle dimensions while including a 3/4" edge radius will be fine. Maybe even better.

Attachments

- Home

- Loudspeakers

- Multi-Way

- Baffle question