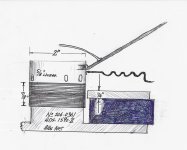

I wonder whether these data sets, together with the voice coil construction image, are sufficient to allow the driver manufacturer, probably a modern Chinese company, to build a driver.

Driver type: dynamic

Cone diameter: 10 inches

Cone material: copolymer

Surround material: butyl rubber

Impedance: 7.6 Ohms

Voice coil diameter: 2 inches

Voice coil former: Kapton

Magnetic flux density: 0.9 Tesla

Magnetic flux: 1.17 x 10^-3 Weber

Credit for picture: tysontom of “classicspeakerpages” forum

Driver type: dynamic

Cone diameter: 10 inches

Cone material: copolymer

Surround material: butyl rubber

Impedance: 7.6 Ohms

Voice coil diameter: 2 inches

Voice coil former: Kapton

Magnetic flux density: 0.9 Tesla

Magnetic flux: 1.17 x 10^-3 Weber

Credit for picture: tysontom of “classicspeakerpages” forum

You would be leaving a lot of things up to their discretion if you tried to do so.

You have nothing there that gives a target or even a neighborhood for basic Thiele/Small parameters, power handling expectations, etc.

You have nothing there that gives a target or even a neighborhood for basic Thiele/Small parameters, power handling expectations, etc.

You’re right, @mattstat.

But, my point of view was that, if we think of it less complex, the dynamic drivers simply consist of two parts; static and moving parts. The static part is the magnet and the moving part is the voice coil with its attached component i.e. bobbin, cone, cap, and suspensions (spider and surround). So, I thought that providing measurable external parameters or physical specification might be usable for the professional to build or, at least, working on some reverse engineerings. Because physical properties would affect electrical properties, but might not vice versa, I’m not sure.

But, my point of view was that, if we think of it less complex, the dynamic drivers simply consist of two parts; static and moving parts. The static part is the magnet and the moving part is the voice coil with its attached component i.e. bobbin, cone, cap, and suspensions (spider and surround). So, I thought that providing measurable external parameters or physical specification might be usable for the professional to build or, at least, working on some reverse engineerings. Because physical properties would affect electrical properties, but might not vice versa, I’m not sure.

For a more professional approach go here for a very good freeware program :

https://www.femm.info/wiki/HomePage

Some loudspeaker related projects are included , transformer examples for ribbon tweeter too!

For the young sophisticated there are student versions of COMSOL Multiphysics! (anything you'll ever need)

https://www.femm.info/wiki/HomePage

Some loudspeaker related projects are included , transformer examples for ribbon tweeter too!

For the young sophisticated there are student versions of COMSOL Multiphysics! (anything you'll ever need)

But you haven't done that for enough items to narrow the design down. Moving mass, Q, Fs, sensitivity, etc. could be nearly anything with the dataset you provided so far. If you want to specify the driver through physical attributes, that's certainly possible, but you need to do it for many more components than you have at this point. Someone is going to make those decisions. Are you comfortable letting the manufacturer make all of them and just taking whatever the driver winds up being?I thought that providing measurable external parameters or physical specification

Yes and no.I wonder whether these data sets, together with the voice coil construction image, are sufficient to allow the driver manufacturer, probably a modern Chinese company, to build a driver.

Driver type: dynamic

Cone diameter: 10 inches

Cone material: copolymer

Surround material: butyl rubber

Impedance: 7.6 Ohms

Voice coil diameter: 2 inches

Voice coil former: Kapton

Magnetic flux density: 0.9 Tesla

Magnetic flux: 1.17 x 10^-3 Weber

Can the same magnetic circuit be built, as shown?

Yes

Hey, even I can, and am a very small speaker manufacturer.

Can even meet all written above specs

But the elephant in the room is: will it sound like the one you are trying to clone?

No way! .... Only by sheer chance, since tons of important data is omitted.

Just starting with:

- Spider diameter / thickness / compliance / mass / shape / height / weight

- Same with cone, adding elasticity, presence/absence of ribs, shape (straight/curvilinear), doping, etc.

- Same with edge (rubber/foam/ cloth), doping.

- Even the dust cap changes sound.

- Adhesives

1 or 2 as reference, a couple more which can be dissected for analysis.

Anything less is not enough.

To make it doable, I expect a minimum order size of 1000 units, that if they can use some existing stuff, such as existing cast frames.

Actually, I have an actual sample. But, the suspicion is if it’s so aged, would its parameters be usable? For example, let’s consider at the spider, would the stiffness be the same as the new one? Or, for the magnet, would its magnetic field/strength still be equal to the new one as well?

https://aac.fr/index_en.php

Also , the finest speakerporn (Do Not Xplode) , 172p PDF :

https://www.loudspeakerindustrysourcebook.com/

http://www.gotomylis.com/

(2nd symbol from the upper right corner)

Also , the finest speakerporn (Do Not Xplode) , 172p PDF :

https://www.loudspeakerindustrysourcebook.com/

http://www.gotomylis.com/

(2nd symbol from the upper right corner)

There's two faces in that coin.Actually, I have an actual sample. But, the suspicion is if it’s so aged, would its parameters be usable? For example, let’s consider at the spider, would the stiffness be the same as the new one? Or, for the magnet, would its magnetic field/strength still be equal to the new one as well?

* Cloner may try to reproduce the worn/tired speaker you have and be reasonably successful, point is that in 2-3 months, as speaker loosens, it may become unusably dark, fluffy, undefined.

* Or he may try to build "the same speaker as it was new"

Problem is he will not have a fresh unused speaker to measure and clone so he will have to extrapolate/guess how did yours sound, say, 10-20 years ago.

Which does not mean he can't build s good speaker or similar to original, simply nobody will be certain, not even you.

Just curious, can you mention Brand and Model of original speaker?

And where was it used?

Also: is there any datasheet or frequency response curve for that speaker?

It won't spell actual build details but provide a definite goal to which clone can be compared. Quite useful.

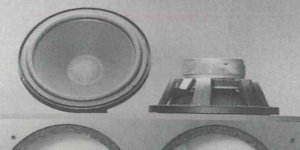

The original speaker is ADS L1590/2’s woofer. It was launched around mid 80s. The youngest among them is about 36 years old, Lol.

It utilizes paper cone technology where they called Stifflite—Stiff & Light, I believe. Regrettably, I don’t have any measurements, but its spec says the crossover point is about 350Hz for the woofers.

The successor, ADS M15, was switched to copolymer cone. However, it also came with stamped frame and tiny magnet, whereas the 1590 featured robust cast frame and full-sized magnet.

It utilizes paper cone technology where they called Stifflite—Stiff & Light, I believe. Regrettably, I don’t have any measurements, but its spec says the crossover point is about 350Hz for the woofers.

The successor, ADS M15, was switched to copolymer cone. However, it also came with stamped frame and tiny magnet, whereas the 1590 featured robust cast frame and full-sized magnet.

Searched something about them.

They seem to be VERY good speakers.

Flat (minus 3 dB) response down to 28Hz is impressive because they were also LOUD

Found some extra data to help cloners, but the cone seems to be unobtanium:

Power-handling for the woofers was top notch with the 2-inch-diameter voice coils with 1.5-inch high windings, giving greater than .5-inch linear overhang.

The woofer's coil former, or bobbin, was made from Kapton

This is doable.

the cone material (referred to as Stiflite) was thick and dense, yet very light.

Where would you find that cone?

Besides, "stiflite" is just a brand, we don't really know its specs, weight, thickness, what it's made of.

Guess it might be made out of regular cellulose paste mixed with some synthetic fiber added .... Nomex?

In a nutshell: "anything can be made, the devil is in the details".

Say ADS or some investor decided to re launch the model.

They might have kept some blueprints, production notes, secret sauce cone paste details, etc. ; that would help a lot ... and even so it wouldn't be easy.

Some Chinese OEM maker will be able to build/assemble them, quickly and for a good price .... but you will need to supply or find proper cones, voice coils, spiders, etc. because those give it it's "voice"

If makers use generic parts ... speaker will "work" but sound is anybody's guess.

They will be able to clone frames and magnets, the non moving parts, that's not that critical.

EDIT:

Given the complications and that you apparently need only 4 of them for some project or to rebuild an old cabinet pair, your best bet will be to search for good woofers, same specs, specially: cast frame, 2" long trow voice coils, long throw suspensions and edges, not too heavy cones, big magnets, and give them a try.

Quite certain very advanced Italian speaker makers will be able to offer something functionally equivalent.

Just curious, did you measure magnet diameter and thickness?

If possible, in mm ; those pesky Imperial units are confusing 🙂

Can you post a couple speaker pictures?

Front/side/back so we know what are we dealing with.

They seem to be VERY good speakers.

Flat (minus 3 dB) response down to 28Hz is impressive because they were also LOUD

Found some extra data to help cloners, but the cone seems to be unobtanium:

Power-handling for the woofers was top notch with the 2-inch-diameter voice coils with 1.5-inch high windings, giving greater than .5-inch linear overhang.

The woofer's coil former, or bobbin, was made from Kapton

This is doable.

the cone material (referred to as Stiflite) was thick and dense, yet very light.

Where would you find that cone?

Besides, "stiflite" is just a brand, we don't really know its specs, weight, thickness, what it's made of.

Guess it might be made out of regular cellulose paste mixed with some synthetic fiber added .... Nomex?

In a nutshell: "anything can be made, the devil is in the details".

Say ADS or some investor decided to re launch the model.

They might have kept some blueprints, production notes, secret sauce cone paste details, etc. ; that would help a lot ... and even so it wouldn't be easy.

Some Chinese OEM maker will be able to build/assemble them, quickly and for a good price .... but you will need to supply or find proper cones, voice coils, spiders, etc. because those give it it's "voice"

If makers use generic parts ... speaker will "work" but sound is anybody's guess.

They will be able to clone frames and magnets, the non moving parts, that's not that critical.

EDIT:

Given the complications and that you apparently need only 4 of them for some project or to rebuild an old cabinet pair, your best bet will be to search for good woofers, same specs, specially: cast frame, 2" long trow voice coils, long throw suspensions and edges, not too heavy cones, big magnets, and give them a try.

Quite certain very advanced Italian speaker makers will be able to offer something functionally equivalent.

Just curious, did you measure magnet diameter and thickness?

If possible, in mm ; those pesky Imperial units are confusing 🙂

Can you post a couple speaker pictures?

Front/side/back so we know what are we dealing with.

Last edited:

Thanks.

Measuring from picture, ferrite magnet is 130 mm diameter by some 20mm thick, a standard size.

Beefy compared to what's usual in 10" speakers, nice magnet.

I use them myself in some of my guitar and Bass speakers.

Your earlier diagram showed a 2" polepiece, 1/4” plate thickness, 7/8" long winding.

Mounted on a cast frame, equivalent ones are available.

Meaning the "mechanical" part can be duplicated with not much trouble.

A same specs Kapton voice coil can be found.

The problem part will be getting that "stiff but light" cone which defines "voice", it also shows a larger than usual edge.

Foam/rubber/cloth?

In general that speaker seems to be doable, problem being that any manufacturer will ask for 500-1000 units to be interested.

That's why I suggested searching for similar specs ones.

Again: Italians make impressive speakers, not only heavyweights like RCF but also smaller factories such as SICA.

https://sica.it

Measuring from picture, ferrite magnet is 130 mm diameter by some 20mm thick, a standard size.

Beefy compared to what's usual in 10" speakers, nice magnet.

I use them myself in some of my guitar and Bass speakers.

Your earlier diagram showed a 2" polepiece, 1/4” plate thickness, 7/8" long winding.

Mounted on a cast frame, equivalent ones are available.

Meaning the "mechanical" part can be duplicated with not much trouble.

A same specs Kapton voice coil can be found.

The problem part will be getting that "stiff but light" cone which defines "voice", it also shows a larger than usual edge.

Foam/rubber/cloth?

In general that speaker seems to be doable, problem being that any manufacturer will ask for 500-1000 units to be interested.

That's why I suggested searching for similar specs ones.

Again: Italians make impressive speakers, not only heavyweights like RCF but also smaller factories such as SICA.

https://sica.it

Some people said the Kapton is just a plastic, so would it be better to use the aluminum instead?

For the edge, the original material is butyl rubber. However, some people also suggest foam edge is more frequently found in the ultra hi-end, still be vintage, speakers; for instance, Infinity, AR, Boston Acoustics, etc., although it has shorter life-time than the rubber. So, is it worth it to switch to foam instead?

Finally, I myself think that the stiff-but-light cone is a perfect option as it has ideal properties and was a creative invention. Nonetheless, My personal believe is it might be categorized in paper category. And it should have lower environmental resistance, i.e., allergic to water. Therefore, whether the “copolymer” material replacing in the successors; ADS M9, M12, M15 series, should be preferable to look for. Does this hypothesis make sense?

For the edge, the original material is butyl rubber. However, some people also suggest foam edge is more frequently found in the ultra hi-end, still be vintage, speakers; for instance, Infinity, AR, Boston Acoustics, etc., although it has shorter life-time than the rubber. So, is it worth it to switch to foam instead?

Finally, I myself think that the stiff-but-light cone is a perfect option as it has ideal properties and was a creative invention. Nonetheless, My personal believe is it might be categorized in paper category. And it should have lower environmental resistance, i.e., allergic to water. Therefore, whether the “copolymer” material replacing in the successors; ADS M9, M12, M15 series, should be preferable to look for. Does this hypothesis make sense?

I strongly believe it is a fools errand to try and duplicate a 4 decade old design. Design has forged ahead in light years since then. Personally, I would look at the big players in the industry for an off the shelf driver ( that will be available in a month, a year, 5 years or more from now ) that works in your cabinet volume and has the requisite bandwidth.

And gold or Titanium are just some metals 😉Some people said the Kapton is just a plastic, so would it be better to use the aluminum instead?

Seriously, kapton is an incredible space age material, Same level as kevlar, Teflon, etc.

It keeps strength up to 400C, incredibly tough, etc.

Aluminum is good but old school, has the important disadvantage that it brakes movement when inside a magnetic field, and absorbs/wastes power sent to voice coil.

So there, kapton is way better.

If at all possible, keep close to original design.For the edge, the original material is butyl rubber. However, some people also suggest foam edge is more frequently found in the ultra hi-end, still be vintage, speakers; for instance, Infinity, AR, Boston Acoustics, etc., although it has shorter life-time than the rubber. So, is it worth it to switch to foam instead?

Otherwise, what's the point?

And those woofers were well advanced compared to others.

Maybe, but we are just guessing.Finally, I myself think that the stiff-but-light cone is a perfect option as it has ideal properties and was a creative invention. Nonetheless, My personal believe is it might be categorized in paper category. And it should have lower environmental resistance, i.e., allergic to water. Therefore, whether the “copolymer” material replacing in the successors; ADS M9, M12, M15 series, should be preferable to look for. Does this hypothesis make sense?

- Home

- Loudspeakers

- Multi-Way

- Are these data sets sufficient to custom-build drivers?