and if not - why not ? - would this simple change bring improvement?

Transducer motor with low thermal modulation

US20040156525A1 - Transducer motor with low thermal modulation

- Google Patents

US5664023A - Low TCR wire in high power audio coils

- Google Patents

Transducer motor with low thermal modulation

US20040156525A1 - Transducer motor with low thermal modulation

- Google Patents

US5664023A - Low TCR wire in high power audio coils

- Google Patents

How did Geddes get a patent in 2003 on Doug Buttons 1994 patent by what appears to me to have been simply re-worded?

Barry.

Barry.

Interesting.

Rather than a frequency response curve which depends on so many factors, I would love to see the basic phenomenon: wire resistivity (or resistance) variation vs. temperature within the possible voice coil temperature range, for all 3 alloys mentioned.

FWIW I do use Cu-Ni (constantan) alloy wires in my amps, I wind my own emitter and current sensing resistors but never imagined making voice coils out of that.

I use 55%-45% Cu-Ni in 0.50mm diameter.

Can´t imagine how meager 2% or 4% Ni can influence much, but I´ll wait until I see the curves.

Rather than a frequency response curve which depends on so many factors, I would love to see the basic phenomenon: wire resistivity (or resistance) variation vs. temperature within the possible voice coil temperature range, for all 3 alloys mentioned.

FWIW I do use Cu-Ni (constantan) alloy wires in my amps, I wind my own emitter and current sensing resistors but never imagined making voice coils out of that.

I use 55%-45% Cu-Ni in 0.50mm diameter.

Can´t imagine how meager 2% or 4% Ni can influence much, but I´ll wait until I see the curves.

and if not - why not ?

Because it partially (but with possible side-effects) fixes a problem that only rarely needs fixing.

With active crossovers this fix isn't needed and with passive crossovers there are enough other issues in their operation that why bother "putting lipstick on a pig".

For home use, I doubt many are cooking their voice coils enough to matter on most music at non-ear-destroying levels.

For dance-clubs, perhaps another matter.

The appeal of high-power PA and dance-club applications has tended to replace the audiophile music customer base and tended to industrial-quality bass speakers rather than quality devices that are loud at home on 10 watts.

B.

Fighting resistance rise with temperature is fine, in principle fighting power compression.

But if your penalty is heavier and more resistive wire, that negates the possible advantage.

To decide we need ... ugh! ..... numbers .... , which are conspicuously missing, specially in the patent application.

But if your penalty is heavier and more resistive wire, that negates the possible advantage.

To decide we need ... ugh! ..... numbers .... , which are conspicuously missing, specially in the patent application.

How did Geddes get a patent in 2003...

He didn't, it's an application only, never proceeded to a patent.*

At least that's what it looks like me, unless the US system is very different to the Australian one that I know.

Best wishes

David

*Probably for the reasons in JMFahey's post.

Last edited:

Fighting resistance rise with temperature is fine, in principle fighting power compression.

But if your penalty is heavier and more resistive wire, that negates the possible advantage.

To decide we need ... ugh! ..... numbers .... , which are conspicuously missing, specially in the patent application.

Exactly, for high power applications you want the lowest mass and the highest conductivity. These low TCR alloys have lower conductivity compared to copper wire of similar mass. The B&C IPAL drivers use aluminum for lower mass; despite it been hard to terminate and of greater resistivity than copper. Increasing driver efficiency reduces power dissipation in the voice coil and so also reduces power compression for a given acoustic output. There is bound to be a figure of merit relating mass and resistivity for voice coil wire, however I don't know it.

…There is bound to be a figure of merit relating mass and resistivity for voice coil wire, however I don't know it.

Compared to copper, aluminum is 61% more resistive, but only weighs 30% as much.

Ignoring thermal effects:

ηo ∝ (BL^2) / (Re * M^2)

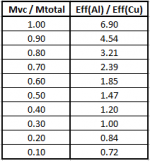

Switching from copper to aluminum with the same wire gauge and coil geometry, BL remains constant. How much efficiency increases will depend on what portion of the moving mass is made up of the voice coil (See attached table). At the upper bounds, if the entire moving mass was made up of the VC, efficiency would be increased by a factor of 6.9 when switching to aluminum wire. If the VC made up half of the moving mass, then the efficiency would increase by factor of 1.47. If the VC only contributed 10% to the total moving mass, efficiency would actually decrease.

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- are there drivers w. voice coil wire per Dr. Geddes patent ?