5V RMS equals the same heating value as 5VDC.

By definition.

Other effects may apply, but the total heat integrated over time is exactly equal.

Not saying they aren't equal, just saying that every filament transformer I have ever dealt with has delivered more than rated voltage (and varies with line voltage), while every DC supply I have ever built was right on the money 100% of the time.

Nope. Actually, the Svetlana 300B is notorious for the frequent filament breakage problems it has always had....

I was impressed with the quality and performance of a pair of Shuguang 300B/CN globes on ac heating.

It is "only theoretical" but it is also something I have observed over the years. All my "vintage" valves/tubes get AC filaments, especially if they are getting on in age.

They last longer with AC and the "decline" in power is much more gradual vs. DC. For me, WWII and earlier globe 1930's valves/tubes all get AC. Newer valves/tubes can have DC though. No problem here with that.

The theory:

1. An AC filament is freeing electrons at a lower temperature across a greater area of the filament than DC (for a given same energy input). This is inherent, due to the cyclical nature of AC. AC is easier on the whole filament than DC heater due to lower skin effect and peak fluctuations (joule heating is peak-to-peak in nature) on surface.

Yes, I admit that this difference is very small. However over a longer period of time AC should increase filament lifespan and perhaps increase trans-conductance vs. DC.

2. With DC you have no cycle, so no potential cooling or relief for weaker parts of the filament. There is an additional benefit to this. Invisible weak points in a filament simply never experience a relief cycle with DC. This suggests that deterioration will likely be faster with DC vs. AC too in potential "weak points" of the filament.

Ian

Dmitry Nizhgorodov made some real measurements of DHTs with AC-heating, and found that hum amplitude is unaffected by increasing the frequency. This pretty well debunks any idea that the hum is thermally derived, and it also makes it very difficult to believe that there is any substantial temperature fluctuation from by 50/60Hz heating.

On Correlation Between Residual DHT Filament Hum and AC Frequency

On the other hand, as Heath has already noted here, the risk to filament life from unregulated heating is real. The attached picture is from the Philips Technical Review of 1956, and underlines the importance of never exceeding the +5% limit of filament voltage, and the benefits of not exceeding the nominal value at all.

The allowable tolerance of Line voltages has in recent years got worse, rather than better. In the UK, and other locations, it is now ±10%, which is an outright threat to the lifetime of rare or expensive DHTs - and certainly not a benefit. And that's before we get into the startup current into cold filaments.

Attachments

For a traditional incandescent light bulb filament, the lifetime is according to the 5th power of the voltage.

A 10% increase of power mains voltage shortens the bulb life to 62% of the same bulb at its rated voltage.

A 10% decrease of power mains voltage lengthens the bulb life to 161% of the same bulb at its rated voltage.

There are differences between an incandescent filament and a vacuum tube filament.

Vacuum tube Direct Heated filaments may be Thoriated, may be coated with Barium, Strontium, or other elements. But they are in free space, just like incandescent bulb filaments.

Vacuum tube filaments used for Indirect Heating of the cathode, have insulating coatings.

But they are not in free space, and incandescent bulb filaments are.

Your mileage with incandescent bulbs, DHT, and Indirect heated tubes may vary.

It is a shame that power mains vary by up to +/- 10%.

I am fortunate, my power mains vary from 117 to 123V, as measured by a True RMS meter (yes, the Heating Power, Not average voltage, and Not Peak voltage related).

I design for 120V, and only have +/- 2.5% RMS variance.

Oh, did I forget to mention that I have never purchased any of those overly expensive boutique tubes.

The moderate cost versions of 300B, 2A3, and indirect heated tubes all work well on my +/- 2.5% power mains.

And most of them have a series resistor to adjust for the slightly high filament secondary rms voltage. And that series resistor gives an intrinsic soft startup for the filaments.

Unregulated brute force DC supplies with CRC filtering also have a series resistor, that gives intrinsic soft startup for the filaments.

But there are other problems with that supply . . .

Unregulated brute force DC for filaments presents another problem, the 3rd harmonic distortion of power mains, especially if the amount of that distortion changes widely over load, time of day, and time of year.

Large changes of power mains 3rd harmonic distortion changes the peak to rms voltage ratio, so a variance of distortion changes the voltage out of an unregulated brute force DC supply.

Measure your power mains 3rd harmonic distortion, at different times of day, week, month, and year.

(Be careful, that measurement is unsafe, unless you know several things . . .

Your test equipment, probes, connectors, power mains details of ground, neutral, hot, etc., and you know how to properly and safely make the measurement).

Safety First!

Prevent the "Surviving Spouse Syndrome"

A 10% increase of power mains voltage shortens the bulb life to 62% of the same bulb at its rated voltage.

A 10% decrease of power mains voltage lengthens the bulb life to 161% of the same bulb at its rated voltage.

There are differences between an incandescent filament and a vacuum tube filament.

Vacuum tube Direct Heated filaments may be Thoriated, may be coated with Barium, Strontium, or other elements. But they are in free space, just like incandescent bulb filaments.

Vacuum tube filaments used for Indirect Heating of the cathode, have insulating coatings.

But they are not in free space, and incandescent bulb filaments are.

Your mileage with incandescent bulbs, DHT, and Indirect heated tubes may vary.

It is a shame that power mains vary by up to +/- 10%.

I am fortunate, my power mains vary from 117 to 123V, as measured by a True RMS meter (yes, the Heating Power, Not average voltage, and Not Peak voltage related).

I design for 120V, and only have +/- 2.5% RMS variance.

Oh, did I forget to mention that I have never purchased any of those overly expensive boutique tubes.

The moderate cost versions of 300B, 2A3, and indirect heated tubes all work well on my +/- 2.5% power mains.

And most of them have a series resistor to adjust for the slightly high filament secondary rms voltage. And that series resistor gives an intrinsic soft startup for the filaments.

Unregulated brute force DC supplies with CRC filtering also have a series resistor, that gives intrinsic soft startup for the filaments.

But there are other problems with that supply . . .

Unregulated brute force DC for filaments presents another problem, the 3rd harmonic distortion of power mains, especially if the amount of that distortion changes widely over load, time of day, and time of year.

Large changes of power mains 3rd harmonic distortion changes the peak to rms voltage ratio, so a variance of distortion changes the voltage out of an unregulated brute force DC supply.

Measure your power mains 3rd harmonic distortion, at different times of day, week, month, and year.

(Be careful, that measurement is unsafe, unless you know several things . . .

Your test equipment, probes, connectors, power mains details of ground, neutral, hot, etc., and you know how to properly and safely make the measurement).

Safety First!

Prevent the "Surviving Spouse Syndrome"

Last edited:

.. Still, I got so sick and tired of posters pushing DC for-sale solutions that I won’t touch any of them with a barge pole regardless of their benefit....

Agree. Too often the 'you need DC on filaments' has a sales pitch after it.

As per the image above, the text states (paraphrasing) voltage +/- 5% of nominal value and if the voltage can be stabilized to within 1%, then -5%, and in some instances -10% is permissible.

Between the lines: If you can stabilize the voltage within 1%, how can it then be that you choose to stabilize it at -5% or -10% of nominal value unless there is a benefit in doing so. ??

Between the lines: If you can stabilize the voltage within 1%, how can it then be that you choose to stabilize it at -5% or -10% of nominal value unless there is a benefit in doing so. ??

Agree. Too often the 'you need DC on filaments' has a sales pitch after it.

I think this is over-reacting and unfair. There are people on this forum who have worked for many years on DC solutions and have plenty of data to back up their work. There are many here who are very grateful for the work they've done.

As per the image above, the text states (paraphrasing) voltage +/- 5% of nominal value and if the voltage can be stabilized to within 1%, then -5%, and in some instances -10% is permissible.

Between the lines: If you can stabilize the voltage within 1%, how can it then be that you choose to stabilize it at -5% or -10% of nominal value unless there is a benefit in doing so. ??

Starving the filament can be useful in some applications. See here an "extreme" application where it's more than 10%:

filament starvation – Bartola(R) Valves

"I will simply stress here that the 01a has its filaments starved. This reduces microphonic noise as well as improve linearity."

Starving the filament can be useful in some applications. See here an "extreme" application where it's more than 10%:

filament starvation – Bartola(R) Valves

"I will simply stress here that the 01a has its filaments starved. This reduces microphonic noise as well as improve linearity."

Steve Bench's starved filament data:

DHT with starved filaments.

Those starving examples look a bit extreme. OK for the purpose of showing what it does but in practice 20% is already a lot and not worth going beyond, IMHO. The distortion can be lower in other ways too. I have done it myself in Mullard style amp using a PCC88 shared between the 2 channels and 2x6DR7 tubes per channel. The PCC88 runs with starved heater at 5.7-5.8V and distortion gets lower. The amp is super quiet with rather basic but decent supply.

With 01A or any other DHT with thoriated tungsten filaments, reducing the filament voltage by ca. 5% on (unused) DHTs can allow them to work at their full potential, and greatly increase the available lifetime.

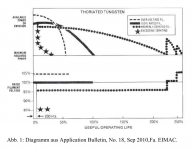

See the attached diagram extracted from an EIMAC app-Note. Note that excessive de-rating (see the curve of big stars) can be as bad as overheating. The damaging effect of over-heating is very obvious, in this data.

That's for Thoriated Tungten filaments.

With oxide-coated filaments, the story is different. There is always a benefit from running them between -5% and +0% of the rated voltage, compared to ±5%, but too much de-rating can shorten the life too.

The reason is the thermal equilibrium of the active ingredient in the coating - usually barium.

Barium is incorporated throughout the coating at manufacture, but is active only at the surface. Its evolution from the sub-surface occurs at a temperature-dependent rate. At rated heating power (so, with 5.0V for 300B), the temperature is sufficient to maintain a proper surface density of Barium. Too much heat (i.e. above 5.0V for 300Bs) always evolves the Barium at a wastefully rapid rate, and thus shortens the filament life in a way that cannot be recovered.

Too low a voltage - over a long interval - can starve the surface of Barium, and degrade the emissive quality. If the underheating is of only a short duration, the equilibrium can be recovered by returning the filament voltage to the rated value for a time.

The level at which under-heating degrades lifetime varies with different coatings, different manufacturers. Of the current manufacturers, for example: EML tell me that their filaments should be run at 5.0V exactly, for longest lifetime, for the reasons noted above; but the Philips data suggests that this is not universal.

See the attached diagram extracted from an EIMAC app-Note. Note that excessive de-rating (see the curve of big stars) can be as bad as overheating. The damaging effect of over-heating is very obvious, in this data.

That's for Thoriated Tungten filaments.

With oxide-coated filaments, the story is different. There is always a benefit from running them between -5% and +0% of the rated voltage, compared to ±5%, but too much de-rating can shorten the life too.

The reason is the thermal equilibrium of the active ingredient in the coating - usually barium.

Barium is incorporated throughout the coating at manufacture, but is active only at the surface. Its evolution from the sub-surface occurs at a temperature-dependent rate. At rated heating power (so, with 5.0V for 300B), the temperature is sufficient to maintain a proper surface density of Barium. Too much heat (i.e. above 5.0V for 300Bs) always evolves the Barium at a wastefully rapid rate, and thus shortens the filament life in a way that cannot be recovered.

Too low a voltage - over a long interval - can starve the surface of Barium, and degrade the emissive quality. If the underheating is of only a short duration, the equilibrium can be recovered by returning the filament voltage to the rated value for a time.

The level at which under-heating degrades lifetime varies with different coatings, different manufacturers. Of the current manufacturers, for example: EML tell me that their filaments should be run at 5.0V exactly, for longest lifetime, for the reasons noted above; but the Philips data suggests that this is not universal.

Attachments

- Home

- Amplifiers

- Tubes / Valves

- Are Psvane (or chinese) 300B tubes durable and reliable ?