Member

Joined 2003

My idea would be to test this is to run the Danley style horn with the HF off, the rest on, and use the diaphragm of the HF section as a microphone to see what is or is not being sent back.

This seems like a great idea to test feasibility of a true ribbon, but I don't have the appropriate "bits"...so please post results!!!

Once again Patrick, where do you get these assumptions from?

Is it from Beyma's white paper?

http://www.beyma.de/fileadmin/seiten/download/pdf/Beyma_2010/TPL-150_en.pdf

All I see there is a comparison with a unknown 3" Ti diaphragm compression driver, with different time scales, and a strange "plateau" is the first ms for the TPL150 (which if real would cause more prejudice than even a long tail happening under -30dB).

Truth is CSD can be arranged to show about anything the person choosing the parameters wants to show...

Earlier in the thread, I made a couple of statements, without presenting any data to back them up. Here they are:

1) At the top end of a compression driver's range, the diahpragm is breaking up. Due to this, the CSD of a compression driver isn't as good as a direct radiator particularly at the upper end. Due to this, I try to use the smallest diaphragm that I can get away with. The use of a small diaphragm does not eliminate the problem, it simply pushes it to a higher frequency. But 20khz is less audible than 15khz, so that's why I do it.

2) Ribbons have cleaner CSD than domes and pistons.

Here's some data to rectify the situation.

First, here are three plots of cumulative spectral delay. In my opinion, these plots are in order of worst to best. The worst is the B&C DE250, in the middle is a Celestion CDX1-1425, and the best is a RAAL ribbon.*

In the CSD plots we see a number of issues:

1) If you look at the two octaves from 4 to 16khz in the DE250, you'll note strong ridges at 4khz, 8khz, and 16khz. Note that they're divisible by each other, which would generally indicate some type of reflection IMHO. The output in these two octaves is very 'hashy' and resonant in the CSD plot of the DE250.

2) In the same two octaves, the Celestion CDX1-1425 'fades to black' in about half the time. The Celestion has only one notable ridge, compared to three in the DE250. More importantly, the Celestion's ridge is very high in frequency, at 16khz.

3) The RAAL ribbon has a cleaner delay across it's entire bandwidth than either compression driver.

If you agree with my assessment, that the ranking goes DE250, CDX1-1425 then RAAL, perhaps you'd like to know my hypothesis on why they behave like this.

Here's my theory:

Sound travels 34 centimeters in a single millisecond. In a compression driver, that means that the first fraction of a millisecond will be spent inside the phase plug. So, BOOM, a ribbon will *always* win at CSD, because a ribbon has no phase plug.

The next problem is the transition from the phase plug to the horn. For instance, let's say your phase plug has a pathlength of 11.33 centimeters, or 4.5". If your wavefront reflects at the exit of the phase plug, than that wave is going to spend an entire millisecond travelling through the phase plug AND it will be out-of-phase with the wavefront that WASN'T reflected.

I hope that makes sense. Basically a fraction of the radiated energy is going to take a direct route, but *another* fraction is going to ping-pong inside the phase plug. And with a 11.33cm phase plug, that's a total pathlength of 34cm long.

Or one millisecond.

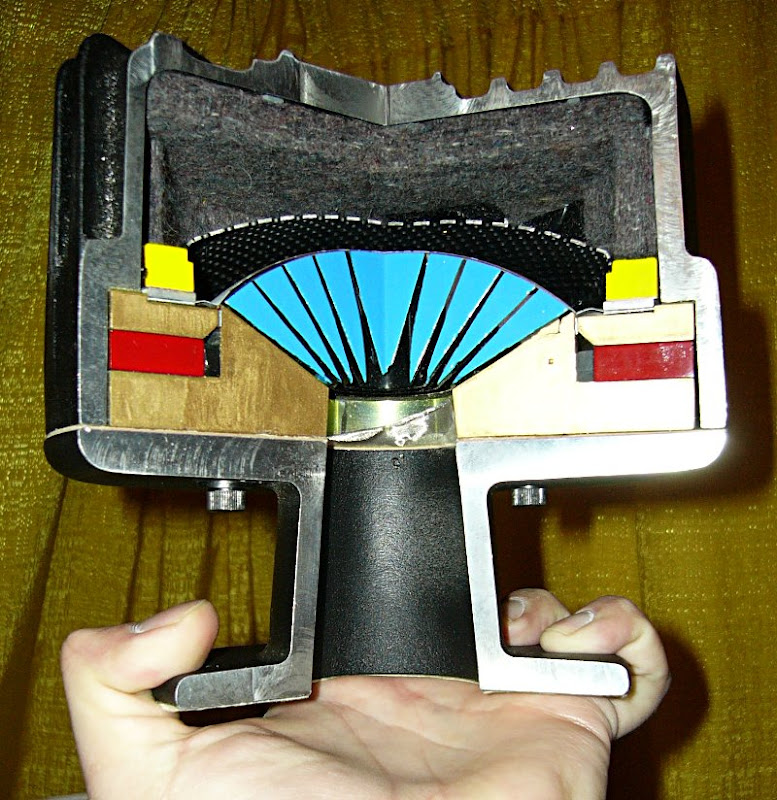

Here's my Celestion CDX1-1425 disassembled. See how it's basically just a dome tweeter with a very small phase plug?

OK if you've made it this far, I commend you, this is a long boring post.

Here's the last part of the puzzle:

If you look at the Celestion, you'll notice that it's CSD isn't just a *little* better than the DE250, it's a *lot* better.

My hypothesis on this is that the expansion rate matters, all the way to the diaphragm.

For instance, if you look at most compression drivers, they have a phase plug that looks like this:

See how there's very high compression for the first five centimeters or so?

IMHO, to reduce diffraction and reflection, we don't want that abrupt change that happens at the exit of the phase plug. We want a smoooooooooooooth transition from phase plug to horn.

And you just can't get that with the phase plug pictured above. (Well, you COULD, but the waveguide would have to be very very narrow.)

I made this picture to illustrate my point.

This is an actual TAD compression driver cut in half, and I've superimposed two waveguides. The first is fifteen degrees; the second is 90.

See how they 90 degree waveguide has an abrupt change in the expansion at the exit from the compression driver? And the 15 degree one does not?

But *both* suffer from the transition at the phase plug.

The CSD of the Celestion and the B&C were measured by Brandon on this QSC waveguide, which has a horizontal coverage that's 90 degrees, the same as my illustration.

I didn't mean to make this The Longest Post Ever, but *that* should explain why ribbons have such great CSD, and why compression drivers often do not.

To sum it up, when I'm looking for a compression driver I want one that's big enough to do the job, but not so big that the CSD gets ugly. Everything else being equal, smaller is better.

I'll end this post with a quote:

"On the second day of my trip to England, we visited the headquarters of KEF’s corporate sibling, Celestion, where we learned a bit about how Celestion drivers are developed and manufactured. While the companies largely exist independently, KEF and Celestion do share some research and development resources—at the time of my visit, Jack Oclee-Brown was working with Celestion to develop very large tweeters. “The success of a driver greatly depends on everything being small,” said Oclee-Brown. “As you make it bigger, the acoustics become more challenging. I’m working to make it as simple as possible.”

* data stolen shamelessly from Augerpro's driver vault (https://sites.google.com/site/drivervault/Home) and the spec sheet of a RAAL ribbon from Ascend Acoustics (http://www.ascendacoustics.com/pages/products/speakers/SRT/Ascend Sierra Ribbon Tower.pdf). Celestion quote from Stereophile. I personally own Gedlee, Kef and Celestion speakers so I may be biased 🙂

Last edited:

Your observation might be correct but I don't think your explanation/theory is.

There is no sound radiated until the exit of the phase plug.

The dimensions are too small to allow sound generation at frequencies of interest before the phase plug exit.

Your observations could equally be the result of suboptimal phase plug design and poor coupling to the waveguide throat.

[QUOTESound travels 34 centimeters in a single millisecond. In a compression driver, that means that the first fraction of a millisecond will be spent inside the phase plug. So, BOOM, a ribbon will *always* win at CSD, because a ribbon has no phase plug.

The next problem is the transition from the phase plug to the horn. For instance, let's say your phase plug has a pathlength of 11.33 centimeters, or 4.5". If your wavefront reflects at the exit of the phase plug, than that wave is going to spend an entire millisecond travelling through the phase plug AND it will be out-of-phase with the wavefront that WASN'T reflected.

I hope that makes sense. Basically a fraction of the radiated energy is going to take a direct route, but *another* fraction is going to ping-pong inside the phase plug. And with a 11.33cm phase plug, that's a total pathlength of 34cm long.][/QUOTE]

There is no sound radiated until the exit of the phase plug.

The dimensions are too small to allow sound generation at frequencies of interest before the phase plug exit.

Your observations could equally be the result of suboptimal phase plug design and poor coupling to the waveguide throat.

[QUOTESound travels 34 centimeters in a single millisecond. In a compression driver, that means that the first fraction of a millisecond will be spent inside the phase plug. So, BOOM, a ribbon will *always* win at CSD, because a ribbon has no phase plug.

The next problem is the transition from the phase plug to the horn. For instance, let's say your phase plug has a pathlength of 11.33 centimeters, or 4.5". If your wavefront reflects at the exit of the phase plug, than that wave is going to spend an entire millisecond travelling through the phase plug AND it will be out-of-phase with the wavefront that WASN'T reflected.

I hope that makes sense. Basically a fraction of the radiated energy is going to take a direct route, but *another* fraction is going to ping-pong inside the phase plug. And with a 11.33cm phase plug, that's a total pathlength of 34cm long.][/QUOTE]

Bear,One of my concerns about the Danley design, and any design that puts LF drivers, or MF drivers in with compression "tweeters" is the pressure in the horn impinging upon the diaphragm of the HF driver. Danley explained this in another post by saying that the ratio of energies going from the diaphragm out was so high that coming back in there would be very little energy for IMD.

With a ribbon in the same hole, I wonder if it is going to still work.

My idea would be to test this is to run the Danley style horn with the HF off, the rest on, and use the diaphragm of the HF section as a microphone to see what is or is not being sent back. Alternately place a microphone set to a suitable FFT analyzer in the position of the HF section...

I always encourage people to test their hypothesis, but a driver driven by an amplifier reacts differently than one used as a microphone.

A driven or shorted driver hardly is moved by SPL, an undriven driver does move, in fact Dave Rat had the unfortunate experience of shattering undriven TAD Be diaphragms when testing LF/MF drivers in close proximity, eliminating the "protection capacitor" in series with the driver eliminated that problem.

Although the THD measurements of the ribbons in the Peavey Versarray 2x12" don't completely address your concern, there are enough attestations about the "cleanliness" of the ribbons even though they are in similar proximity to the mid cones as a DSL Synergy that I don't think intermodulation distortion caused by mid proximity is much of a concern.

The 1x12" Versarray crosses the 12" to the ribbons, requiring a crossover in the 2000 Hz range (for loud use), the beaming of the 12" that high has been noted.

Art

Attachments

Your observation might be correct but I don't think your explanation/theory is.

There is no sound radiated until the exit of the phase plug.

The dimensions are too small to allow sound generation at frequencies of interest before the phase plug exit.

Your observations could equally be the result of suboptimal phase plug design and poor coupling to the waveguide throat.

As I understand it, even if sound is not being radiated pathlength still matters.

For instance:

An externally hosted image should be here but it was not working when we last tested it.

Picture the air moving through that phase plug. The phase plug is about 8cm deep. Even if the path is too small to contain a wave, those air molecules are still moving at the speed of sound.

So the pathlength still matters, the path matters, there is a time delay that's introduced as the air molecules are moving through the phase plug.

If we wanted to get ultra-complex we could model the behavior of the phase plug at the various transitions, figure out what shape is the least turbulent, determine what compression ratio is ideal.

But I don't have any way to do that 🙂

Barring that, there's some generalizations that I've noticed in various compression driver and horn combos:

1) a high compression ratio sounds 'strained.'

2) the best sounding waveguides and compression driver combos that I've heard are be the ones that have very little diffraction all the way to the surface of the diaphragm.

3) You can see this in a CSD plot quite readily. For instance, take a compression driver and bolt it to a horn. Now make it off center, just a fraction of a centimeter. You'll see the diffraction in the CSD plot.

It's the reason I mount drivers like this, another neat trick I stole from the Summas

The dimensions of a phase plug are quite large compared to the molecules in air vibrating at frequencies of interest.Your observation might be correct but I don't think your explanation/theory is.

There is no sound radiated until the exit of the phase plug.

The dimensions are too small to allow sound generation at frequencies of interest before the phase plug exit.

Your observations could equally be the result of suboptimal phase plug design and poor coupling to the waveguide throat.

The sound in a compression driver begins radiating from the diaphragm, SPL is highest at that point, and reduces pretty much at the inverse distance law from there (6 dB reduction for each doubling of distance), through the phase plug, the mouth and the rest of the horn.

As far as the CSD being better for the ribbons, comes down to moving mass- the ribbons have the least (and can't go as low) the tiny diaphragm has a bit more mass, and the larger diaphragm that can go lower in frequency has still more mass, so takes a bit longer to come to rest.

And I'm sure some might easily hear the difference in transient response listening to them in an anechoic environment.

Last edited:

Here's some quick math, basically exploring 'how audible is the excellent CSD of a ribbon?'

At four kilohertz, a DE250 'fades to black' in three milliseconds.

At four kilohertz, a CDX1-1425 'fades to black' in one millisecond.

There are four thousand cycles per second in a sound that's 4khz.

A 4000khz signal lasts one quarter of a millisecond.

Therefore, *neither* device is truly capable of resolving a 4khz signal. Both are going to smear it; they would have to 'fade to black' in one quarter of a millisecond to accomplish that.

But this is all a question of degrees, and the CSD of the Celestion indicates that it's closer to that ideal.

Not to get all subjective, but I find that the Celestion and small ribbons both have that 'delicate' airy sound which sounds very 'hifi'.

At four kilohertz, a DE250 'fades to black' in three milliseconds.

At four kilohertz, a CDX1-1425 'fades to black' in one millisecond.

There are four thousand cycles per second in a sound that's 4khz.

A 4000khz signal lasts one quarter of a millisecond.

Therefore, *neither* device is truly capable of resolving a 4khz signal. Both are going to smear it; they would have to 'fade to black' in one quarter of a millisecond to accomplish that.

But this is all a question of degrees, and the CSD of the Celestion indicates that it's closer to that ideal.

Not to get all subjective, but I find that the Celestion and small ribbons both have that 'delicate' airy sound which sounds very 'hifi'.

Seems like you are saying "in order to have a smooth expansion from the diaphragm to the throat, we need to get rid of this thing designed to create a smooth expansion from the diaphragm to the throat".

Seems like you are saying "in order to have a smooth expansion from the diaphragm to the throat, we need to get rid of this thing designed to create a smooth expansion from the diaphragm to the throat".

nah I'm saying that the transition from the air all the way to the diaphragm should be as seamless as possible.

The actual shape will depend on the vertical and horizontal coverage of the waveguide

For instance, the optimum phase plug for a 90x90 degree waveguide will not be the same shape as 60x60 degree waveguide

Probably the fundamental problem is that the phase plug on compression drivers is optimum for a much much smaller coverage angle, about 10-20 degrees. I believe this is due to the fact that waveguides are a fairly recent trend, and the phase plugs on compression drivers are optimized for horns. (Basically phase plugs haven't changed all that much in 90 years.)

And horns have narrow coverage at the throat.

BUT - there is hope. Because there are *some* compression drivers that have a phase plug with a much more rapid expansion. Take a look at a Celestion. You'll see what I mean. Or a BMS.

Didn't Geddes solve this like a decade ago?

https://www.google.com/patents/US20...a=X&ei=dZddUsuMK-voiwKN6oCYBw&ved=0CEUQ6AEwAg

The sound in a compression driver begins radiating from the diaphragm, SPL is highest at that point,

But that's my point. It's not sound, it's "hydraulic pressure", isn't it?

If I'm right, then this can not be correct:

and reduces pretty much at the inverse distance law from there (6 dB reduction for each doubling of distance), through the phase plug, the mouth and the rest of the horn.

The sound in a compression driver begins radiating from the diaphragm, SPL is highest at that point,

But that's my point. It's not sound, it's "hydraulic pressure", isn't it?

If I'm right, then this can not be correct:

That would be pneumatic.

Hydraulic is fluid, not air.

Last edited:

Your observations could equally be the result of suboptimal phase plug design and poor coupling to the waveguide throat.

Hi Frank

As I point out in one of my patents on phase plugs, basically they are all suboptimal owing to a error in the Smith Phase Plug derivation that is used in virtually all concentric phase plugs. So I would tend to believe that this is the culprit (if there is one).

That would be pneumatic.

Hydraulic is fluid, not air.

When I studied Acoustics in school the first class was "Acoustics in Fluid Media" and we viewed all media as a fluid. We did not distinguish between a gas and a liquid.

Bear,

a driver driven by an amplifier reacts differently than one used as a microphone.

Art

Hi Art

In theory, as long as the device stays linear, all transducers are what are called reciprocal - they can be driven or they can drive. This is a principle that is often used to calibrate microphones. You have to keep the levels low if the device is a microphone, but I would suspect that a ribbon would be fine as a microphone - some microphones are ribbons. It may "react" differently driving or driven, but it is a predictable difference that can be accounted for.

I didn't make my point very well.

If the dimensions are too small to allow sound radiation then transfer of pressure from the piston to the mouth impedance is almost instantaneous.

I understand the effect in air is not as linear as in water but the principle holds, I think.

Quote:

The sound in a compression driver begins radiating from the diaphragm, SPL is highest at that point,

But that's my point. It's not sound, it's "hydraulic pressure", isn't it?

If I'm right, then this can not be correct:

Quote:

and reduces pretty much at the inverse distance law from there (6 dB reduction for each doubling of distance), through the phase plug, the mouth and the rest of the horn.

Last edited:

Your observations could equally be the result of suboptimal phase plug design and poor coupling to the waveguide throat.

Here's another way to look at the diffraction problem.

In the waveguide at the top, we have a shape that's basically similar to my Summas that are sitting here.

A ninety degree waveguide with diffraction treatment at the mouth and the throat of the waveguide.

The size of the mouth dictates how low the directivity goes. If you can find the space for a box that's half a meter across, you'll get directivity control down to about 900hz.

But another way to fight diffraction would be to have the horn mouth set at the exact same angle as the exit of the compression driver. For instance, if the compression driver exit is fifteen degrees, then the horn is fifteen degrees.

Unfortunately at some point the sound has to enter the room 🙂

So what if we take that line, and we sloooooooowly bend it until it's perpendicular to the compression driver?

If we do that, we end up with two half circles on each side of the compression driver.

An externally hosted image should be here but it was not working when we last tested it.

^^^ I see that circular roundover in the JBL Biradials, the Avantgarde spherical horns, and the LeCleach horns. And obviously, you can 'squash' the curve to change the loading, frequency response shape, and the directivity.

But the general idea, of the sound exiting the compression driver then slooooooowly curving into the room is the same.

I can't see any reason that the shape has to be perfectly circular or spherical though.

For instance, you could extend the depth to get more loading.

Or you could *reduce* the depth to get less loading.

At the same time, you're also changing the directivity of the device.

Squash that circle down into an ellipse, and you get the curve of the Econowave horns:

or this:

You could really go crazy with this. Take that curve and wrap it all the way around the enclosure.

Last edited:

I didn't make my point very well.

If the dimensions are too small to allow sound radiation then transfer of pressure from the piston to the mouth impedance is almost instantaneous.

I understand the effect in air is not as linear as in water but the principle holds, I think.

Interesting, I did not know that.

So you're saying that the air in the phase plug moves faster than the speed of sound?

If that is the case, then it helps explain one of the mysteries of the Danley Paraline.

The Danley Paraline is basically a bizarre looking phase plug. And the boxes that use the Paraline use digital delay. This only makes sense, because of the long pathlength. But one of the bizarre things about the Paraline is that the *highs* are delayed, not the lows. They're delayed by 10 centimeters (0.314ms).

And I'd always scratched my head on why this is, considering the pathlength for the highs is longer than the pathlength for the lows.

Interesting.

That doesn't look like an OS profile wave guide. And where's the matching to the exit angle that it has?In the waveguide at the top, we have a shape that's basically similar to my Summas that are sitting here.

Geez! I'm getting picky.

Last edited:

That doesn't look like an OS profile wave guide. And where's the matching to the exit angle that it has?

Geez! I'm getting picky.

oblate spheroidal and conical are basically the same curve.

The only difference is at the throat and at the mouth.

I should have put a short curve at the throat in my pic, about 1" in depth.

My main point is that the transition from the exit of the compression driver doesn't have to happen in the span of a single inch. The transition can happen over the entire length of the horn, and if you do that, you end up with something that looks like the LeCleach curve.

If you take that curve and squash it, you end up with something that looks like what JBL has been using for about a decade now.

An externally hosted image should be here but it was not working when we last tested it.

I used to have one of these speakers back in the 90s. Another example of the biradial curve.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Are Most Horns Fundamentally Flawed?