Hello All,

I have an AR turntable from the mid ‘80s. I think it is an XE model, with Sumiko Premier MMT tone arm and currently a Sumiko Blue Point EVO III cartridge. Over the years it has undergone quite a bit of modification. Merrill mods, including springs with foam damping, dampening material added to the sub chassis, and new motor and bearing oil. The motor did not last long, and in 2004 was replaced with an Origin Live DC motor and controller, with a new pulley and belt.

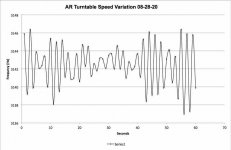

It has had infrequent use for the last 10 years, but I am considering using it to transfer some of my favorite LPs to a digital format. So, I recently did a little cleanup and maintenance, and the unit seems in reasonably good condition. I recently came across a great free program for measuring wow and flutter ( A.N.T. Audio :: Welcome :: Library ) Using Analogue Productions Test LP I measured W&F for this turntable. The original specification was for 0.04% DIN weighted, the current measurement indicated 0.0587%rms, also DIN weighted, which seems OK for a turntable of this vintage. But when I look at the speed variation (see attachment) I am having second thoughts.

So, the question is, do you think I can improve on the speed stability? And if so, what would you recommend?

Cheers,

ceulrich

I have an AR turntable from the mid ‘80s. I think it is an XE model, with Sumiko Premier MMT tone arm and currently a Sumiko Blue Point EVO III cartridge. Over the years it has undergone quite a bit of modification. Merrill mods, including springs with foam damping, dampening material added to the sub chassis, and new motor and bearing oil. The motor did not last long, and in 2004 was replaced with an Origin Live DC motor and controller, with a new pulley and belt.

It has had infrequent use for the last 10 years, but I am considering using it to transfer some of my favorite LPs to a digital format. So, I recently did a little cleanup and maintenance, and the unit seems in reasonably good condition. I recently came across a great free program for measuring wow and flutter ( A.N.T. Audio :: Welcome :: Library ) Using Analogue Productions Test LP I measured W&F for this turntable. The original specification was for 0.04% DIN weighted, the current measurement indicated 0.0587%rms, also DIN weighted, which seems OK for a turntable of this vintage. But when I look at the speed variation (see attachment) I am having second thoughts.

So, the question is, do you think I can improve on the speed stability? And if so, what would you recommend?

Cheers,

ceulrich

Attachments

It looks like the speed varies periodically with every revolution of the platter. It could be worn bearing. Does a visual check while the platter rotates show anything?

The foam damping added to help reduce spring resonances has probably been slowly changing its chemical composition due to old age (don't we all ? ) and requires replacing although I removed it from a deck on the manufacturers advice to improve clarity.

Looking at the original brochure it says the springs are "damped " which amounts to the same thing .

Three point springing was a big deal in the ,80,s my deck has this type of suspension but one spring is adjustable via an allan key to "tune the suspension .

Not a bad deck from what I remember --24 pole synchronous motor , not cheap back then.

Looking at the original brochure it says the springs are "damped " which amounts to the same thing .

Three point springing was a big deal in the ,80,s my deck has this type of suspension but one spring is adjustable via an allan key to "tune the suspension .

Not a bad deck from what I remember --24 pole synchronous motor , not cheap back then.

You can buy brass shim stock at many hobby shops; one of our local hardware stores even carries it -- K & R is one brand, IIRC.

Major pain in the what-sits, for sure, but some of that old vinyl just cries out for a listen ..

Sorry to see that about a test record .. if that's it.

Regards

Major pain in the what-sits, for sure, but some of that old vinyl just cries out for a listen ..

Sorry to see that about a test record .. if that's it.

Regards

Last edited:

Thanks to everyone that responded.

lcsaszar, yes, I also noted that variation. I will repeat the measurement a few more times to see if it is consistent, or just a random variation. Regarding any observations, if I observe the small gap (about 1/8”) between the platter edge and the curved edge of the arm board, I do not notice any variation as the platter rotates.

rayma, I will have to do some research to determine what is acceptable for LP diameter and radius, but I made the following measurement. Using the 50:1 scale of an engineer's ruler I measured the diameter at 11.88’ and the radius at 5.92’.

duncan2, I have not looked under the hood, so to speak, to see the condition of the foam dampers, but I am not sure I see how that might effect rotation speed.

Rick PA Stadel, can you explain what the brass shim stock would be used for?

Cheers,

ceulrich

lcsaszar, yes, I also noted that variation. I will repeat the measurement a few more times to see if it is consistent, or just a random variation. Regarding any observations, if I observe the small gap (about 1/8”) between the platter edge and the curved edge of the arm board, I do not notice any variation as the platter rotates.

rayma, I will have to do some research to determine what is acceptable for LP diameter and radius, but I made the following measurement. Using the 50:1 scale of an engineer's ruler I measured the diameter at 11.88’ and the radius at 5.92’.

duncan2, I have not looked under the hood, so to speak, to see the condition of the foam dampers, but I am not sure I see how that might effect rotation speed.

Rick PA Stadel, can you explain what the brass shim stock would be used for?

Cheers,

ceulrich

Are pressing irregularities the main cause???

It's probably the most important point. I ran the program and saw a similar periodicity. Both of my (elderly) HFS75s are pressed slightly off centre. Not by much, probably 0.5mm but I can see the pu moving slightly on each rev. Sadly the HiFi News Analogue Test LP doesn't have a 3kHz tone.

But it's an interesting topic isn't it. We all obsess over motors and controllers, while we're playing records that come with eccentricity built in. I remember reading somewhere an opinion that fine tuning VTA was pointless because it was all wiped out in LP unevenness.

Make sure the test record is punched concentric before going too much farther.

It's probably the most important point. I ran the program and saw a similar periodicity. Both of my (elderly) HFS75s are pressed slightly off centre. Not by much, probably 0.5mm but I can see the pu moving slightly on each rev. Sadly the HiFi News Analogue Test LP doesn't have a 3kHz tone.

But it's an interesting topic isn't it. We all obsess over motors and controllers, while we're playing records that come with eccentricity built in. I remember reading somewhere an opinion that fine tuning VTA was pointless because it was all wiped out in LP unevenness.

Sure. You cut little narrow strips, a millimeter or two wide, a centimeter or 1-1/2 long, off the 2 thinner sheets. As you're lowering the record onto the post, try fitting the thinnest one sticking up along the post, causing a slight eccentricity. Then try it at different locations 'til you find one that's 'just right'. Use the thicker one if necessary, but not to the point of requiring more than 15 or 20 grams of force to get it over the spindle. Since AR seems to be pretty careful with their tolerances you don't want to force it.

Once you find the best location, grab a felt tip and mark the record on both sides. As tempting as it might be, try to resist Scotch-taping the shim stock right to the record: By putting in the little right-angle bends, the shim will act much thicker and alter the result.

Regards

Once you find the best location, grab a felt tip and mark the record on both sides. As tempting as it might be, try to resist Scotch-taping the shim stock right to the record: By putting in the little right-angle bends, the shim will act much thicker and alter the result.

Regards

Last edited:

Rick PA Stadel, thanks for the additional info. From your description, I assumed your method tries to compensate for a hole that is slightly out-of-round, which is what causes an eccentricity. However, you use the phrase “causing a slight eccentricity”, so I wonder if I really understand. Does this method compensate for an out-of-round hole, or to create an eccentricity to compensate for an eccentricity caused by some other mechanism? I am thinking here about an eccentricity in the physical record (the hole not exactly centered in the record) versus an eccentricity between the hole and the grooves.

As mentioned previously, I noted the approximate 2-cycle per minute variation in the data and wondered if it was real or just a random event. So, I repeated the measurement 5 times, and none of these measurements showed a similar 2-cycle per minute variation.

Cheers,

ceulrich

As mentioned previously, I noted the approximate 2-cycle per minute variation in the data and wondered if it was real or just a random event. So, I repeated the measurement 5 times, and none of these measurements showed a similar 2-cycle per minute variation.

Cheers,

ceulrich

Never mind the measurement or messing with shims, can you hear that it is off, if not why worry.

The test LP center hole must be punched exactly concentric with the grooves,

or you will get this sort of speed variation from it being off-center.

The AR spindle was made to NAB specs, so many LPs will fit it a little tight.

This is unlike most turntables, which have their spindles a little under size,

so LPs will just drop right on, but can wow depending on happenstance.

or you will get this sort of speed variation from it being off-center.

The AR spindle was made to NAB specs, so many LPs will fit it a little tight.

This is unlike most turntables, which have their spindles a little under size,

so LPs will just drop right on, but can wow depending on happenstance.

Last edited:

hello rayma, could you explain the NAB specs? I believed the dimensions of the phonograph record is specified by RIAA. It says the center hole diameter is 7.26 mm (+0.025 -0.05). From these numbers I conclude the maximum diameter of the spindle should be 7.21 mm (0.284") for tight fit. As a manufacturer I would chose 7.2 mm, no less, no more.The test LP center hole must be punched exactly concentric with the grooves,

or you will get this sort of speed variation from it being off-center.

The AR spindle was made to NAB specs, so many LPs will fit it a little tight.

This is unlike most turntables, which have their spindles a little under size,

so LPs will just drop right on, but can wow depending on happenstance.

What does NAB say about it?

NAB says 0.2830" spindle diameter.

LP standards:

Standards table

http://www.richardhess.com/tape/history/NAB/NAB_Disc_Standard_1964_formatted_text_and_graphics.pdf

LP standards:

Standards table

http://www.richardhess.com/tape/history/NAB/NAB_Disc_Standard_1964_formatted_text_and_graphics.pdf

Last edited:

collinstuart, that’s a really good point, yes, it does sound fine, at least on my office system. I listened to some piano music and did not detect any pitch changes.

Temaad, I get your point that the quality of my digital copies will only be as good as the quality of the T/T system, but an external motor positioning is not practical in my situation.

Over the past few days, I have been reading a lot of T/T reviews and threads relating to T/T and speed stability, but nothing seems similar to my observations. Almost all the graphics of T/T speed have been collected using the Feickert PlatterSpeed app which collects data at about 10 samples per second. The software I am using outputs data at 1 point per second. I am wondering if the difference in methods is part of the problem?

As suggested previously in this thread, the cyclic variations (at 27/min) are more related to an eccentricity in the record rather than T/T problems. Thinking about correcting for eccentricities: correcting the test record only makes the data look better, it does not change how any other records will be played; and correcting all records seems unpractical. Getting back to the T/T itself, I did the speed test 5 consecutive times, the results are shown in the attachment. Anyone care to offer a suggestion of what might be causing the “modulation” of the 27/min oscillations, as marked by the red ellipse, or the gradual speed decline, indicated by the red line? One more point, this record does have a slight warp, I estimate at 2-5mm, I counted the frequency at about 1 per second.

Cheers,

ceulrich

Temaad, I get your point that the quality of my digital copies will only be as good as the quality of the T/T system, but an external motor positioning is not practical in my situation.

Over the past few days, I have been reading a lot of T/T reviews and threads relating to T/T and speed stability, but nothing seems similar to my observations. Almost all the graphics of T/T speed have been collected using the Feickert PlatterSpeed app which collects data at about 10 samples per second. The software I am using outputs data at 1 point per second. I am wondering if the difference in methods is part of the problem?

As suggested previously in this thread, the cyclic variations (at 27/min) are more related to an eccentricity in the record rather than T/T problems. Thinking about correcting for eccentricities: correcting the test record only makes the data look better, it does not change how any other records will be played; and correcting all records seems unpractical. Getting back to the T/T itself, I did the speed test 5 consecutive times, the results are shown in the attachment. Anyone care to offer a suggestion of what might be causing the “modulation” of the 27/min oscillations, as marked by the red ellipse, or the gradual speed decline, indicated by the red line? One more point, this record does have a slight warp, I estimate at 2-5mm, I counted the frequency at about 1 per second.

Cheers,

ceulrich

Attachments

Ultimately, we'd need to measure the turntable edge and not use a test LP. There are tachometers that don't appear to use a measuring strip, but none that I've seen are affordable and accurate enough.

I still think that for your average LP from the 60's to 90's there's probably more wow in the LP than there is in the TT.

Either way, on my system I can't hear anything obvious in the test tone, regardless of what the program is measuring....

I still think that for your average LP from the 60's to 90's there's probably more wow in the LP than there is in the TT.

Either way, on my system I can't hear anything obvious in the test tone, regardless of what the program is measuring....

Almost all my vinyl is from the 70's and there are probably 2 or 3 that I bother with eccentricity *adjustment*, and it's because I heard a problem. Initially I just stood over it, staring straight down, and tried to give the album edge a bump with a small glass ashtray or the butt of a C-battery, at just the right moment. Eventually I decided shim strips and a Flair felt tip was less tedious.

There surely is something specious (if that's the right word😱) going on with those measurements -- imagine the horsepower it would take to cause such speed variations on an ongoing basis.

My T/T is a late 1960's AR, but the way, so the great majority of records cause no audible problem.

Regards

There surely is something specious (if that's the right word😱) going on with those measurements -- imagine the horsepower it would take to cause such speed variations on an ongoing basis.

My T/T is a late 1960's AR, but the way, so the great majority of records cause no audible problem.

Regards

...Anyone care to offer a suggestion of what might be causing the “modulation” of the 27/min oscillations, as marked by the red ellipse, or the gradual speed decline, indicated by the red line?

Cheers,

ceulrich

I suggest this might be all suspension related. I've witnessed my plater suddenly go into a freeform wobble for a second or two out of nowhere and then it's as is something gives, the suspension settles and we're back to the well performing AR 3 point suspension again doing it's thing. I can visualise it in the graphs; the 'bind' and the slow-down, the 'give' and short speed spike.

Thorens TD-160 Super: 7.24 mm (just measured with a caliper)7.1882 mm & no fraction / inch equivalent

Cheers

I have done a lot of reading, and made a lot of measurements on this T/T.

I checked everything I could think of including the following:

Tracking force at 2.2g

Overhang

VTA

The “bounce”

Centering of the sub-chassis

“Clocking” of the inner and outer platters

Consistent spacing between the lower edge of the platter to the plinth

Cleaned and “talked” the belt

Adjusted tension on mounting screw on motor mounting plate

Every time I actually changed anything I conducted another measurement. The only change I noted was when I adjusted the tension on the mounting screw holding the motor mounting plate. There was a subtitle, but noticeable improvement in the pattern of speed variations, but still not nearly as steady as seen with published T/T reviews using the Feickert PlatterSpeed app.

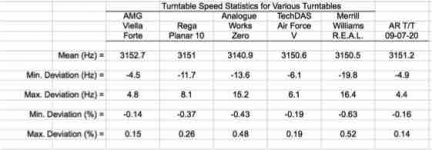

So, I thought I would compare my measurements to those from other T/Ts. I did a Google search for T/T reviews and took the first five that had PlatterSpeed data. The attachment shows the results along with a measurement for the AR T/T. The AR T/T seems quite comparable to the best of this grouping.

I am left with the conclusion that the apparent speed variation is a function of the difference in measurement methods and not a function of the T/T.

Cheers

I checked everything I could think of including the following:

Tracking force at 2.2g

Overhang

VTA

The “bounce”

Centering of the sub-chassis

“Clocking” of the inner and outer platters

Consistent spacing between the lower edge of the platter to the plinth

Cleaned and “talked” the belt

Adjusted tension on mounting screw on motor mounting plate

Every time I actually changed anything I conducted another measurement. The only change I noted was when I adjusted the tension on the mounting screw holding the motor mounting plate. There was a subtitle, but noticeable improvement in the pattern of speed variations, but still not nearly as steady as seen with published T/T reviews using the Feickert PlatterSpeed app.

So, I thought I would compare my measurements to those from other T/Ts. I did a Google search for T/T reviews and took the first five that had PlatterSpeed data. The attachment shows the results along with a measurement for the AR T/T. The AR T/T seems quite comparable to the best of this grouping.

I am left with the conclusion that the apparent speed variation is a function of the difference in measurement methods and not a function of the T/T.

Cheers

Attachments

There surely is something specious (if that's the right word😱) going on with those measurements -- imagine the horsepower it would take to cause such speed variations on an ongoing basis.

Oscillations in a drive system whether caused by record eccentricity, motor speed variation, or drive effects do not require significant inputs of power to the system as the oscillation is a very modest variation around a mean speed. The example of an eccentric record is easiest to understand as there is no drive speed variation and only very tiny variation in the frictional components at the stylus interface.

- Home

- Source & Line

- Analogue Source

- AR Turntable Question