A B&C DE-07 might be one candidate and make the horn a bit taller than original. Maybe there's something less expensive (?)

What your thoughts on the vanes? In one regard they make for a rock solid horn.

These days a 3D print could make sense.

Smith Selsted Tweeters

What your thoughts on the vanes? In one regard they make for a rock solid horn.

These days a 3D print could make sense.

Smith Selsted Tweeters

Attachments

Last edited:

that looks good - how large would you make the horn? - would it retain the "vanes"? 120 degree arc?

I wonder how a chopped down KSN1016 with step-up transformer would do?

cardboard and hot glue might work well enough for testing (?)

I wonder how a chopped down KSN1016 with step-up transformer would do?

cardboard and hot glue might work well enough for testing (?)

Yeah cardboard or hot wire cut foam, for the vanes.

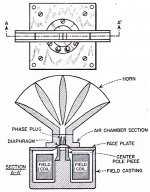

Looks like basic exponential horns x4

It would be a adventure in Horn Response.

Getting the dimensions of one section

Then multiple by 4 in the model

Reading the linked article was pretty fun actually.

Looks like the design for the smaller horn was shooting for 5K upward

Even if not a perfect horn to others, I find the aesthetics and early challenges found

in the creation very interesting

Looks like basic exponential horns x4

It would be a adventure in Horn Response.

Getting the dimensions of one section

Then multiple by 4 in the model

Reading the linked article was pretty fun actually.

Looks like the design for the smaller horn was shooting for 5K upward

Even if not a perfect horn to others, I find the aesthetics and early challenges found

in the creation very interesting

Attachments

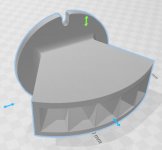

I was just playing around and tried to make a 2 kHz horn for 1" CD. Maybe it is not worth the effort, but I just wanted to try that out. I followed the article and tried to make a 90 degree horn with 5 channels. I must have made some mistake in the process, since the horn is slightly less than 70 degrees. I checked my calculations against another spreadsheet (which might contain the same mistake I did, but I doubt) and I calculated the horn area in Hornresp, which is certainly true🙂

I calculated all parameters according to the article and then I divided the width of the horn into 5 cells and mirrorred those to get the full horn. Below are the values I used:

c 34400 cm/s

S0 6,4516 cm2

f0 2000 Hz

t 2,54 cm

fi 90 deg

Sm 25,8169103 cm2

L 6,470691164 cm

fc 586,6524765 Hz

d 3,247237634 cm

Is there an explanation why the horn is narrower than I expected?

I calculated all parameters according to the article and then I divided the width of the horn into 5 cells and mirrorred those to get the full horn. Below are the values I used:

c 34400 cm/s

S0 6,4516 cm2

f0 2000 Hz

t 2,54 cm

fi 90 deg

Sm 25,8169103 cm2

L 6,470691164 cm

fc 586,6524765 Hz

d 3,247237634 cm

Is there an explanation why the horn is narrower than I expected?