That would be a personal thing, because if you get nit-picky about it, oil impregnated bearings should be replaced, never "re-oiled", mainly because by the time you notice something wrong with them, they are truly shot. Foreign and worn off material gets lost in the pores of the bearing and there isn't any good way to actually get it all back out, not to mention clearance widens. However, in practice, the life of them can be at least doubled if they are cleaned and re-lubricated before they are ever allowed to load up and seize. ...

My first job involved, among other things, maintaining 30's to 50's vintage teleprinters. They used oilite (sintered) bearings in many places, including as friction dampers in the print head. When they lost their efficiency, I would:

1. Put them in a small tray full of light machine oil.

2. Heat the tray with an acetylene torch until the oil "boiled" in the bearings. They would bubble and emit clouds of dirty oil.

3. When the oil ran clean, I'd drain and cool them.

4. Sit them on my finger, fill the centre with oil, then put my thumb over the other end and squeeze. If oil oozed out of the pores, the bearing was good for re-use.

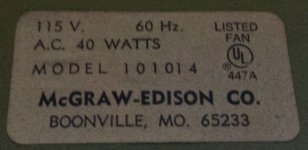

I put some 3 in 1 motor oil in the bearings and the fan is about as smooth as I've ever seen any fan. I left it on for 2 hours straight last night to see if the oil fixed the hot motor issue, well no, it was hot enough that I really didn't want to touch it more than a second.

I also let it cool down, then ran it for a half an hour on 115v instead of 125v, and it still got just as hot, just as quick, on 115 as on 125.

So really I'm still not sure whether I should restore this fan, or toss it?

Anyone?

Posting some pictures of the fan would be really helpful. My aunt and uncle collected vintage fans made in the 1920s onwards. Shaded pole induction motors run very hot, nature of the beast, and after an hour or so of operation are too hot to touch comfortably. I suspect your fan is just fine, however I would never leave an antique fan running unattended, and fitting an appropriately sized slow blow fuse would not be a bad idea if you can fit in somewhere in the base for example.

Note that there are other hazards that are of concern; injury due to contact with metal fan blades due to very coarse fan guards, and electrical shock due to wiring problems and insulation break down in the motor windings.

Note that there are other hazards that are of concern; injury due to contact with metal fan blades due to very coarse fan guards, and electrical shock due to wiring problems and insulation break down in the motor windings.

Posting some pictures of the fan would be really helpful. My aunt and uncle collected vintage fans made in the 1920s onwards. Shaded pole induction motors run very hot, nature of the beast, and after an hour or so of operation are too hot to touch comfortably. I suspect your fan is just fine, however I would never leave an antique fan running unattended, and fitting an appropriately sized slow blow fuse would not be a bad idea if you can fit in somewhere in the base for example.

Note that there are other hazards that are of concern; injury due to contact with metal fan blades due to very coarse fan guards, and electrical shock due to wiring problems and insulation break down in the motor windings.

If it's pics you want, you got it

Can you explain more why you'd not run them unattended, and also, would you run a vintage tube amp unattended, and would you run a modern fan unattended? Also I'd definitely be okay with putting in a fuse.

This fan is modern enough that you'd really have to try to get your finger eaten

As far as the wiring goes, (as you can see) it's pretty sturdy, however I can't say much about the windings breaking down, as they do get hot, however as you can see in the pics, it looks very clean and almost new.

Thanks for helping me out.

Attachments

Can you explain more why you'd not run them unattended, and also, would you run a vintage tube amp unattended, and would you run a modern fan unattended? Also I'd definitely be okay with putting in a fuse.

<snip>

Combination of age, designs where safety was not a paramount concern, and the possibility that if something goes wrong and no one is around that a fire could ensue. It happens.

I no longer own any vintage tube amps, but when I did I never left them on when I was not going to be nearby for an extended period of time.

Depends on the modern fan as to whether or not I would leave it running unattended or not.

I have in the recent past had an inexpensive asian made electric heater with all of the required safety markings (counterfeit I'd wager) that spewed flames and set its plastic case on fire - had we not been in the room at the time we might have lost the house.

Edit: I'm reasonably sure that the thing in the glass tube is a thermal cut out. I remember seeing these in 1960s vintage model railroad power packs.

Combination of age, designs where safety was not a paramount concern, and the possibility that if something goes wrong and no one is around that a fire could ensue. It happens.

I no longer own any vintage tube amps, but when I did I never left them on when I was not going to be nearby for an extended period of time.

Depends on the modern fan as to whether or not I would leave it running unattended or not.

I have in the recent past had an inexpensive asian made electric heater with all of the required safety markings (counterfeit I'd wager) that spewed flames and set its plastic case on fire - had we not been in the room at the time we might have lost the house.

Edit: I'm reasonably sure that the thing in the glass tube is a thermal cut out. I remember seeing these in 1960s vintage model railroad power packs.

Actually I can agree with most of your reasoning. Sorry to hear about your encounter with that heater

I figured that was a thermal switch (finally its obvious that its not a mercury switch as everyone was so sure it was

So overall, how do you think the fan looks, (especially the windings), does it look fit for use in your opinion (obviously I would never hold you to it/responsible for anything).

I'd say enjoy the fan cautiously, but keep an eye on it during early days in particular. I'm just leery of leaving anything old on unattended. Definitely change the cord, put a fuse in the hot conductor and since it has a metal housing I would put a three wire cord on it and ground it for safety.

Well I'm back here again.

Painted the fan, and noticed when putting the fan back together, the motor was making a slight rubbing noise when spun, after taking it apart many times, I found nothing touching the rotor, so the only thing it could be is the bearings in the front, as when only the rotor attached to the rear bearings are spinning, I hear nothing.

It is only a very slight noise, much quieter than when you rub your palms of your hands together, and the fan still takes about 20seconds to spin down, which is about as long as it took before painting. Since the blades are not perfect, it does shake a bit on startup and spindown, however I did notice a slight knocking noise while it shakes like this now, which It didn't have before painting.

I did accidently force a screw that wasn't totally aligned properly into the bracket that secures the back bearing to the casing, which may have ever so slightly bent that bracket, meaning the front bearing is rubbing, but I can't tell.

How can I tell if I've damaged the bearing? I cut a small piece of tape to cover the hole in the bearing where the shaft goes, but I did not cover the entire bearing, like I said, just the hole where the shaft should go, did I mess up?

Thanks.

Painted the fan, and noticed when putting the fan back together, the motor was making a slight rubbing noise when spun, after taking it apart many times, I found nothing touching the rotor, so the only thing it could be is the bearings in the front, as when only the rotor attached to the rear bearings are spinning, I hear nothing.

It is only a very slight noise, much quieter than when you rub your palms of your hands together, and the fan still takes about 20seconds to spin down, which is about as long as it took before painting. Since the blades are not perfect, it does shake a bit on startup and spindown, however I did notice a slight knocking noise while it shakes like this now, which It didn't have before painting.

I did accidently force a screw that wasn't totally aligned properly into the bracket that secures the back bearing to the casing, which may have ever so slightly bent that bracket, meaning the front bearing is rubbing, but I can't tell.

How can I tell if I've damaged the bearing? I cut a small piece of tape to cover the hole in the bearing where the shaft goes, but I did not cover the entire bearing, like I said, just the hole where the shaft should go, did I mess up?

Thanks.

Last edited:

Okay I'm fairly sure the bearing is not happy.

I found that if I tilt the fan to the side a bit while it is spinning down, the rubbing noise gets worse.

Is there any way to save this fan???

I do think I bent the bracket and its making the bearings rub because a few times that I put the fan back together it would be very hard to spin until I actually tapped the bracket in the back with some considerable force, then it really freed up the motor.

I found that if I tilt the fan to the side a bit while it is spinning down, the rubbing noise gets worse.

Is there any way to save this fan???

I do think I bent the bracket and its making the bearings rub because a few times that I put the fan back together it would be very hard to spin until I actually tapped the bracket in the back with some considerable force, then it really freed up the motor.

Last edited:

Okay I'm fairly sure the bearing is not happy.

I found that if I tilt the fan to the side a bit while it is spinning down, the rubbing noise gets worse.

Is there any way to save this fan???

I do think I bent the bracket and its making the bearings rub because a few times that I put the fan back together it would be very hard to spin until I actually tapped the bracket in the back with some considerable force, then it really freed up the motor.

You are probably panicking over nothing.

It could be just the commutator or windings vibrating because you're fiddling with its magnetic field. Magnetic fields do make the coils vibrate and that will produce some noise. It happens occasionally on my Sanyo.

My Sanyo does the exact same thing when the fan blades are held left or right and it does it whenever it feels like it too.. Yet it has still been going strong and still goes strong day after day. And has been that way for 30+ years.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- General Interest

- Everything Else

- Antique Fan - Too Hot????