A little OT: Cabinet Materials

I'll suggest it again -- oftentimes there will be a "non-working" or "parts" Hewlett Packard units from the 1970's and 1980's on the 'Bay. I picked up a couple HP 5328a frequency counters (back when the economy was really in the tank) and you can't replicate the basic carcase/rails type chasis construction for less than $150. Sometimes these things are for sale in "lots". Also, look for the HP and Harrison power supplies, these have enormous heat sinks, fans, shielded receptacles etc. The last HP6129C I bought cost more to ship than the auction price. (I'll put a picture up on www.tech-diy.com )

I'll suggest it again -- oftentimes there will be a "non-working" or "parts" Hewlett Packard units from the 1970's and 1980's on the 'Bay. I picked up a couple HP 5328a frequency counters (back when the economy was really in the tank) and you can't replicate the basic carcase/rails type chasis construction for less than $150. Sometimes these things are for sale in "lots". Also, look for the HP and Harrison power supplies, these have enormous heat sinks, fans, shielded receptacles etc. The last HP6129C I bought cost more to ship than the auction price. (I'll put a picture up on www.tech-diy.com )

Jocko and Eric,

C'mon folks, be friends!

Jocko,

have to second Eric's housing considerations. Not as a new law .... but methinks that housing construction influences an amp's sound. I have tried out this several times although i did not go as far as to use copper. A pain to machine and an almost bigger pain to listen to my buddy Peter Hartmann's comments about stupid neurotic audiophiles while he is maching it.

But i listened to / compared SS amps previoulsy inhabiting an alu housing and now living in their new copper home. Nice improvement, more musical, more involving, some grainy nastiness disappeared.

Same with housings having magnetic components here and there; recently i built my amps strictly non-magnetic and feel it is a nice improvement compared to steel housings.

Sublte difference but there. Hence, me builds his amps meanwhile from mostly plywood. For said reasons.

OTOH, Vinylsavor's system is in fact the best sounding system i ever heared and the amp housings mostly consist of sheet steel profiles (magnetic) and alu profiles and a lot of air surrounding iron and tubes. And only some plywood, for cosmetical reasons.

Eric,

thank you for the compliment, have to struggle now to earn it. ... 🙂

Were oversized used ones so that i would not have to worry about insufficient heatsinking. Do i have to trash them now?

Oh yes, i know, i will use the heatsinks for my Nixie tube wall clock's PS 🙂 . Will have a shunt regulator for the B+ and heaps of current sources to adjust each Nixie's segment for equal brightness 🙂

Oh, but he does, not rain forest but concert hall, he outed himself lately 🙂, be hard with him but don't be injust..

How do i get the hunch your rant results from accumulated discomfort? Hmmh, must be the fact that i cannot spot in this thread what triggered it. Except that tiny pun. But you were adressing stuff from outside this thread.

Accumulating anger is ...a 30 second bomb .. TICK! ...a 29 second bomb .. TICK! ...a 28 second bomb .. TICK! ...a 27 second bomb .. TICK! ...a 26 second bomb .. TICK! ...a 25 second bomb .. TICK! .......

Me 2 has a row with Jocko now and then (just recently, because of corrosive attitude) but the majority of his posts i feel to be helpful and enlightening. Having struggles with him does not keep me from liking and respecting him. As far as i sense valuable contributions, technical stuff, jokes, insights, whatever, i am glad to participate. Whenever something i read upsets me (not only with Jocko), i acknowledge the usable/enjoyable portion and prefer to refuse the invitation to feel bad. And if i decide to speak up against the bad vibrations, i do so instantly, i do not let my discomfort accumulate. Like housebreaking a puppy 🙂 . The puppy also learns for which actions he is cuddled and for which he is spanked (but only if he can correlate action and response).

May i invite anyone to try this system out?

contributes a lot to preventing the forum from getting messy, IMO. Take the best, ignore the rest ( "... refuse the rest" if it suits you) and do so at once.

The more of us try this out and start to enjoy it, the better for our forum.

C'mon folks, be friends!

Jocko,

have to second Eric's housing considerations. Not as a new law .... but methinks that housing construction influences an amp's sound. I have tried out this several times although i did not go as far as to use copper. A pain to machine and an almost bigger pain to listen to my buddy Peter Hartmann's comments about stupid neurotic audiophiles while he is maching it.

But i listened to / compared SS amps previoulsy inhabiting an alu housing and now living in their new copper home. Nice improvement, more musical, more involving, some grainy nastiness disappeared.

Same with housings having magnetic components here and there; recently i built my amps strictly non-magnetic and feel it is a nice improvement compared to steel housings.

Sublte difference but there. Hence, me builds his amps meanwhile from mostly plywood. For said reasons.

OTOH, Vinylsavor's system is in fact the best sounding system i ever heared and the amp housings mostly consist of sheet steel profiles (magnetic) and alu profiles and a lot of air surrounding iron and tubes. And only some plywood, for cosmetical reasons.

Eric,

thank you for the compliment, have to struggle now to earn it. ... 🙂

you are torturing me, i just bought alu heatsinks for my ASKA amp. §$%& !!Jocko, have you actually tried an amp with copper heatsinks for example ? .........Yeah, I thought not !.

Were oversized used ones so that i would not have to worry about insufficient heatsinking. Do i have to trash them now?

Oh yes, i know, i will use the heatsinks for my Nixie tube wall clock's PS 🙂 . Will have a shunt regulator for the B+ and heaps of current sources to adjust each Nixie's segment for equal brightness 🙂

And when did you last spend a week in a rainforest, and reference your ears to NATURAL sounds.

Oh, but he does, not rain forest but concert hall, he outed himself lately 🙂, be hard with him but don't be injust..

How do i get the hunch your rant results from accumulated discomfort? Hmmh, must be the fact that i cannot spot in this thread what triggered it. Except that tiny pun. But you were adressing stuff from outside this thread.

Accumulating anger is ...a 30 second bomb .. TICK! ...a 29 second bomb .. TICK! ...a 28 second bomb .. TICK! ...a 27 second bomb .. TICK! ...a 26 second bomb .. TICK! ...a 25 second bomb .. TICK! .......

Me 2 has a row with Jocko now and then (just recently, because of corrosive attitude) but the majority of his posts i feel to be helpful and enlightening. Having struggles with him does not keep me from liking and respecting him. As far as i sense valuable contributions, technical stuff, jokes, insights, whatever, i am glad to participate. Whenever something i read upsets me (not only with Jocko), i acknowledge the usable/enjoyable portion and prefer to refuse the invitation to feel bad. And if i decide to speak up against the bad vibrations, i do so instantly, i do not let my discomfort accumulate. Like housebreaking a puppy 🙂 . The puppy also learns for which actions he is cuddled and for which he is spanked (but only if he can correlate action and response).

May i invite anyone to try this system out?

contributes a lot to preventing the forum from getting messy, IMO. Take the best, ignore the rest ( "... refuse the rest" if it suits you) and do so at once.

The more of us try this out and start to enjoy it, the better for our forum.

Hello Bernard and all,

Thankyou for your reply, and for vindicating my observations.

Jocko has much valuable long term experience and knowledge, and has much to contribute to the fellows here.

Also Jocko's health is in a seriously bad way, and I know by personal experience that being unwell can contribute adversely to the tone of ones' communications, so therefore we should keep this in mind and give due allowance.

It is mostly a case of understanding Jocko's sometimes bent sense of humour, and indeed he has a fine sense of things funny.

Also I suspect, like me , that he does not suffer fools gladly, and nothing wrong with that in my opinion.

Bernard you always astound me with your gift of communication, despite English not being your first language - congratulations to you.

Unfortunately I'm getting late for an appointment and must go .......

Regards, Eric.

Thankyou for your reply, and for vindicating my observations.

Since my post, Jocko went to the trouble to contact me by email, and we have shared some interesting information, and I now regard him in a different light and would say we are now friends.Jocko and Eric,

C'mon folks, be friends!

Jocko has much valuable long term experience and knowledge, and has much to contribute to the fellows here.

Also Jocko's health is in a seriously bad way, and I know by personal experience that being unwell can contribute adversely to the tone of ones' communications, so therefore we should keep this in mind and give due allowance.

It is mostly a case of understanding Jocko's sometimes bent sense of humour, and indeed he has a fine sense of things funny.

Also I suspect, like me , that he does not suffer fools gladly, and nothing wrong with that in my opinion.

Bernard you always astound me with your gift of communication, despite English not being your first language - congratulations to you.

Unfortunately I'm getting late for an appointment and must go .......

Regards, Eric.

Member

Joined 2002

In regards to different metals causing different effects I can totally agree in principal even if I haven't done the A/B how does it sound now? Every substance is going to have a mechanical effect on everything it touches. I would bet the type of metal the housing of your RCA plugs create transients that someone would be able to hear. Chassis material is a lot easier to believe than my last statement. Has anyone tried carbon & kevlar composites? That ought to be pretty inert, but then what about the RF? What a can of worms! What about brass? Bells are made from bronze, that could sound good and is not all copper. I actually want to use some very dense wood sometime soon. Just need to get to that saw mill.

Member

Joined 2002

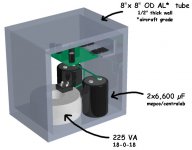

Picture making software.

jason,

The 3D software used is Alias Sketch -- an old antique that i know well, still runs some dozen major OS revisions after it last shipped/

Prep work (line drawings) were done in Adobe Illustrator or in VectorWorks.

Post render stuff done in PhotoShop.

This is just a quick and nasty sketch... one of my various daytime vocations has me doing 3D visualizations some of them can be seen here http://www.hd3dmovies.com/

dave

JasonL said:What program did yu use to make this pic?

jason,

The 3D software used is Alias Sketch -- an old antique that i know well, still runs some dozen major OS revisions after it last shipped/

Prep work (line drawings) were done in Adobe Illustrator or in VectorWorks.

Post render stuff done in PhotoShop.

This is just a quick and nasty sketch... one of my various daytime vocations has me doing 3D visualizations some of them can be seen here http://www.hd3dmovies.com/

An externally hosted image should be here but it was not working when we last tested it.

dave

David,

Why should the housing construction be without influence if even putting the amp on a fancy Sicomin platform (Carbon/Kevlar composite with hard styrofoam core) changes sonics.

I made some experiments with carbon fibre tubing, not promising at all, too ringy.

if you hit such a tube, the clanky, almost glass-like sound could fry your ears.

What is promising is using the carbon composite tubing with a core of

"fluid metal" (epoxy filled with 70volume% of metal powder), wood and epoxy, wood and elastic polyurethane adhesive, anything paralyzing the high-Q resonance. But i listend to the $$$ Wilson tonearm, sounds like plastic. It has such a carbon tube.

Have a look on the Analogue board, http://www.diyaudio.com/forums/showthread.php?s=&threadid=3665

for a tonearm where the arm wand material is vital, even there one has to try it out. I can plan a lot, most of the tonearm is engineering work. Tonearm wand is witchcraft.

I planned to have both my tonearms having exchangeable tonearm wands and well-described and easy to manufacture mechanical interfaces so that a wide variety of tonearm wands can be tried out, even self-built ones.

Bronze: Dieter Ennemoser uses a bronze basket for his big C37 speaker and claims this to be one of the causes for its musicality. Well, got reliable reports of that speaker, must be gorgeous.

Well, he too practices witchcraft 🙂

Why should the housing construction be without influence if even putting the amp on a fancy Sicomin platform (Carbon/Kevlar composite with hard styrofoam core) changes sonics.

Thatch_Ear said:I... Has anyone tried carbon & kevlar composites? That ought to be pretty inert, but then what about the RF? What a can of worms! What about brass? Bells are made from bronze, that could sound good and is not all copper. ..

I made some experiments with carbon fibre tubing, not promising at all, too ringy.

if you hit such a tube, the clanky, almost glass-like sound could fry your ears.

What is promising is using the carbon composite tubing with a core of

"fluid metal" (epoxy filled with 70volume% of metal powder), wood and epoxy, wood and elastic polyurethane adhesive, anything paralyzing the high-Q resonance. But i listend to the $$$ Wilson tonearm, sounds like plastic. It has such a carbon tube.

Have a look on the Analogue board, http://www.diyaudio.com/forums/showthread.php?s=&threadid=3665

for a tonearm where the arm wand material is vital, even there one has to try it out. I can plan a lot, most of the tonearm is engineering work. Tonearm wand is witchcraft.

I planned to have both my tonearms having exchangeable tonearm wands and well-described and easy to manufacture mechanical interfaces so that a wide variety of tonearm wands can be tried out, even self-built ones.

Bronze: Dieter Ennemoser uses a bronze basket for his big C37 speaker and claims this to be one of the causes for its musicality. Well, got reliable reports of that speaker, must be gorgeous.

Well, he too practices witchcraft 🙂

Cheap Fix

Hi Bernard,

Years ago I replaced the broken aluminium alloy arm on my old Dual 12?? with a thin walled brass tube from an aero modellers shop, and soldered a brass plate to the ent to mount the cartridge.

This setup proved to be nicely musical in my memory - At least it worked !.

Eric.

Hi Bernard,

Years ago I replaced the broken aluminium alloy arm on my old Dual 12?? with a thin walled brass tube from an aero modellers shop, and soldered a brass plate to the ent to mount the cartridge.

This setup proved to be nicely musical in my memory - At least it worked !.

Eric.

This is kind of a late reply to this thread but... All of your at the beggining were talking about getting sheet metals to make your chassis. I guess this sounds dumb, but how do you connect the sheets to make a box. Is a welding torch required, or am I just missing something?

Mark

Mark

Well, you could weld it, but you'd have to be a good welder to make it look nice. I just use brackets, works well enough for me...

I am still not understanding what brackets you use, like just a right angle bracket with bolts that go through it and the metal?

- Status

- Not open for further replies.

- Home

- General Interest

- Everything Else

- Aluminum For Chassis'