High temperature epoxy putty will also work for your application. However the powder coat will have two different finishes due to the different substrates. Most putty of that type can handle 350C, and the curing ovens top out at 200-259, so there's some margin there.

I would suggest using regular epoxy or body putty instead, and forgoing powder coating. Brush on a few coats of primer, sand and spray on some matte black paint. Finish with a coat of spray on lacquer. I use the little cans from auto stores. They don't wear as well as powder coat, but for one-offs do just fine - and can be done all by yourself.

I would suggest using regular epoxy or body putty instead, and forgoing powder coating. Brush on a few coats of primer, sand and spray on some matte black paint. Finish with a coat of spray on lacquer. I use the little cans from auto stores. They don't wear as well as powder coat, but for one-offs do just fine - and can be done all by yourself.

Some sprays can offer very nice finishes, professional if you will. when prep and good primer and paint is well executed and temps and humidity play nice.

For cases low shine mattes blacks look great. A little outside the box but for some metal surfaces Ill use a simple good quality rust inhibiting primer after whatever preparation measures are taken. Then lay a matte black paint down with a fine to a more textured roller depending what looks better there.

Matte black rust inhibiting type paints finish off excellent this way. Aside from house paints I wasnt near close to satisfied after applying any other paint this way but it works for that matte black.

Depending on temperatures and humidity some of the rust paints can take up to a couple weeks to fully cure and harden. Some types are designed to stay pliable, they never fully harden, so keep that in mind too.

Before the hardening type cures you can crease it with a light finger nail several days after applying. I did the fender wells of a pristine vintage car this way and thought disaster is striking with a bad batch of paint that isnt drying oh no Im screwed. In the end it cured to pretty durable stuff. Not as touch as polymer powders but very resistant to chipping or lifting. Much more so than off the shelf rattle can paints including the same stuff I rolled on. Unless your automotive paint guy can mix and fill rattle cans on spot I stay away from them. Always found the shelf spray paints chip far too easily no matter how progressively meticulous I became while using them. But paints evolve too maybe they improved lately.

For cases low shine mattes blacks look great. A little outside the box but for some metal surfaces Ill use a simple good quality rust inhibiting primer after whatever preparation measures are taken. Then lay a matte black paint down with a fine to a more textured roller depending what looks better there.

Matte black rust inhibiting type paints finish off excellent this way. Aside from house paints I wasnt near close to satisfied after applying any other paint this way but it works for that matte black.

Depending on temperatures and humidity some of the rust paints can take up to a couple weeks to fully cure and harden. Some types are designed to stay pliable, they never fully harden, so keep that in mind too.

Before the hardening type cures you can crease it with a light finger nail several days after applying. I did the fender wells of a pristine vintage car this way and thought disaster is striking with a bad batch of paint that isnt drying oh no Im screwed. In the end it cured to pretty durable stuff. Not as touch as polymer powders but very resistant to chipping or lifting. Much more so than off the shelf rattle can paints including the same stuff I rolled on. Unless your automotive paint guy can mix and fill rattle cans on spot I stay away from them. Always found the shelf spray paints chip far too easily no matter how progressively meticulous I became while using them. But paints evolve too maybe they improved lately.

I'd embrace the utilitarian, industrial look. Black finish will make the holes and joins less obvious.

Otherwise, make an oversize faceplate (2-3mm each edge) to hide the "faults" as suggested post 10. Black box and white faceplate - chic!

Otherwise, make an oversize faceplate (2-3mm each edge) to hide the "faults" as suggested post 10. Black box and white faceplate - chic!

Thanks all - this is a very useful discussion. I'm not going for 100% professional finish, just something that sits well in the living room and doesn't look too shabby.

I was thinking of channelling inspiration from an AC Cobra:

Power coated white, with the blue Edcors. Something like this:

But without the wooden ends.

I'll be asking the techs at the uni today if they could weld up the edges for me, but I could probably live with the small gaps. And there is always the epoxy mentioned earlier.

The guy who can do the powder coating for me does alloy wheels and the like - I guess he would have to fill in scrapes / dents etc, so it may be something he could do.

I was thinking of channelling inspiration from an AC Cobra:

An externally hosted image should be here but it was not working when we last tested it.

\Power coated white, with the blue Edcors. Something like this:

But without the wooden ends.

I'll be asking the techs at the uni today if they could weld up the edges for me, but I could probably live with the small gaps. And there is always the epoxy mentioned earlier.

The guy who can do the powder coating for me does alloy wheels and the like - I guess he would have to fill in scrapes / dents etc, so it may be something he could do.

I've used this, though not with powder coating, but should handle the heat treatment: https://www.google.com/search?q=Blu...=chrome..69i57j69i60&sourceid=chrome&ie=UTF-8

GM

GM

An update - I went ahead and got the chassis powder coated. Looks great.

I then started getting the holes drilled. Using 'proper' workshop-grade equipment, under expert supervision from a technician, I was able to do the top surface. A lot better than the kitchen table, a scale print out and a hand drill!

Still to do the power valve sockets, the front and rear.

If I were to do it again, I'd obviously do the holes first...

I then started getting the holes drilled. Using 'proper' workshop-grade equipment, under expert supervision from a technician, I was able to do the top surface. A lot better than the kitchen table, a scale print out and a hand drill!

Still to do the power valve sockets, the front and rear.

If I were to do it again, I'd obviously do the holes first...

Attachments

Cool result, congratulations 🙂

I suggest you either accept corner gaps *or* add stiffening there so they can´t move relative to each other-

MIG would have been the best, but you could cut sections of L shaped aluminum extrusiom and rivet or bolt them to corner insides, because if you just apply some kind of filler, relative motion or pressure will tear or at least crack it out.

It will act as a relible filler only if piece is rigid, but don´t trust it to provide rigidity by itself.

I suggest you either accept corner gaps *or* add stiffening there so they can´t move relative to each other-

MIG would have been the best, but you could cut sections of L shaped aluminum extrusiom and rivet or bolt them to corner insides, because if you just apply some kind of filler, relative motion or pressure will tear or at least crack it out.

It will act as a relible filler only if piece is rigid, but don´t trust it to provide rigidity by itself.

Well that didn't go well...

Another update on this. And not a positive one.

The lesson here is be patient and get your holes drilled before powder coating...

The coating just peeled off when I removed the masking tape on my preamp chassis - see attached.

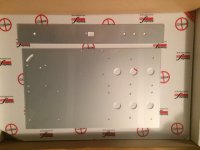

So I gave up and ordered the two chassis from Schaeffer / Front Panel Express. I'm very impressed. The ease of importing from AutoCAD and processing the order, all the way to the packaging (attached). OK, it costs a bit. But the time I would have saved as well as the quality makes up for it.

Highly recommended so far.

Another update on this. And not a positive one.

The lesson here is be patient and get your holes drilled before powder coating...

The coating just peeled off when I removed the masking tape on my preamp chassis - see attached.

So I gave up and ordered the two chassis from Schaeffer / Front Panel Express. I'm very impressed. The ease of importing from AutoCAD and processing the order, all the way to the packaging (attached). OK, it costs a bit. But the time I would have saved as well as the quality makes up for it.

Highly recommended so far.

Attachments

The lesson here is be patient and get your holes drilled before powder coating..

Thats but one lesson.

The coating just peeled off when I removed the masking tape on my preamp chassis - see attached.

This is due to the Al. surface not being cleaned and treated with an etch prior to powder application and baking. I've seen this occur on switchboard enclosures for a Naval project I worked on years ago. The pealing became apparent half way through assembly and wiring about 150 boards in various states of completion . Due to high QA requirements every panel had to be stripped and re-coated.

This idiot paint contractor was 'lucky' in that the faulty coating came off relatively easily due to such poor prep treatment.

Correctly cleaned and etched aluminum or even zinc sealed steel does not do that even after harsh post-paint cutout modification. The coating will crack if panel is bent or folded and melt if localised heating occurs while cutting, but it will not flake like that.

So, make sure the powder coating 'professional' your using knows what happened to last effort and then does the correct prep work in future.

Many of these guys have had long experience spraying 'wet' paint finishes and I reckon many have brain damage from the fumes... I know many enjoy that sweet smelling thinners and solvent aroma and the 'high' way too much.

If they try to suggest it flaked due to mechanical damage like drilling holes and masking tape... don't argue, just find a true professional paint shop for the new case panels. Take faulty panel to another paintshop and they will confirm what I say here.

Powder coat is all well and good, anodising costly but far more durable.

I don't like the inherent 'orange peel' effect PC has... much prefer a spray 2pak epoxy finish myself.

Last edited:

Great points made by Shhh its me - pretty much summarizes what I have read on getting a proper paint finish on aluminum.

TIG? that's overkill. There's a zinc-based rod called Alumiweld (high temp solder, actually) that can be used to fill in holes like that using a propane or MAP gas torch as heat source. No nasty flux, either. Youtube is full of videos on its use.

Wow, never heard of this stuff, looks easy enough.

- Status

- Not open for further replies.

- Home

- Design & Build

- Construction Tips

- Aluminium enclosure - how to cover the gaps before powder coating?