Hello! I've got an Altec 604-8G speaker and the horn is loose. It rocks back and forth side to side and I'm wondering how to tighten it. The upper part of the horn is still firmly glued in place, so I imagine it's the lower section. I've seen pictures and videos and mentions of two accessible screws that should be visible when looking into the horn; however, these don't exist on my speakers. Seems like this is some variant without accessible screws. That said, how do I tighten down the horn? Thanks!

Greets!

If I follow, they're behind the felt cover. Oops! Caught out by the missing response(s) again.

If I follow, they're behind the felt cover. Oops! Caught out by the missing response(s) again.

The screws may be positioned like in Crowe's E-800 (behind the felt cover)Seems like this is some variant without accessible screws. That said, how do I tighten down the horn? Thanks!

Probably difficult to get a decent screwdriver angle without screws through the horn throat.

Hence the loose horn...

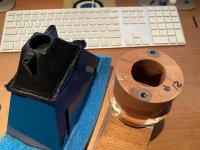

Thanks for the replies. Here are some pictures of the horn and a short video. As you can see the holes are not visible when looking into the horn so perhaps they are indeed under the felt. That said any tips to remove the felt from around the horn? I think this is preferred as opposed to messing with the cone.

Attachments

I’ve seen a few images online - I believe on Lansing Heritage - that show something like this… these are the Urei speakers of course but effectively the same. This has the screws accessible from inside the horn unlike mine. I worry about damaging the cone, etc. trying to get at the screws.

Attachments

Last edited:

I have not removed the felt before so cannot help there. Hopefully someone who knows will see this thread.

GM, the H was the first with the Mantaray and the last of the Alnicos.

GM, the H was the first with the Mantaray and the last of the Alnicos.

If the driver was mine, I'd mash through the felt with a screwdriver rather than removing it.That said any tips to remove the felt from around the horn?

Should be easy enough to locate, might use a toothpick to probe first.

From this 3D print replica replacement, looks like the screw positions are more of a straight shot than I'd have thought:

I once pierced my left ear with a Phillips screwdriver bit when a Milwaukee drill fell off a bench while working on the floor, going through felt won't be nearly as messy 😉

Art

Yeah, memory failed me again. Frankly, having been 'weened' on an original field coil, the only later model I bothered to consider buying was the 'E' Super.

Judging by what’s on the net, there are only two screws per horn, they are Philips head and I would bet my bottom dollar, it’s a number 2.

........and this from googling:

Carefully unglue the felt ring around bakelite horn. Do not unglue it from the paper cone! Take a carefull look under the felt ring, there are two screws situated at the top and bottom. Carefully, with the right screwdriver and twizzers, unscrew both and remove the original horn.

- Home

- Loudspeakers

- Multi-Way

- Altec 604-8G Loose Horn