Hello All

I'm doing a knock-off of the "Alpha Line" that was in A.E. a couple years back.

It's a straight line T/L. Inside its 7"x7" W to just shy 0f 32"(17.78 X 17.78 x 81 cm)

Right now I'm putting the base coats of shellac on before I mix in some sparkle blue

pearl-ex powder. Jordan 92s drivers are waiting to go in. I hope the pic uploads.

I'm about to order 2" spikes (5cm). Anyone know if thats about right? Also I'm

getting fiberglass fill as the design allows a shorter line than if polyfill were used.

Has anyone else measured a difference between various fills?

Regards

Lucius

I'm doing a knock-off of the "Alpha Line" that was in A.E. a couple years back.

It's a straight line T/L. Inside its 7"x7" W to just shy 0f 32"(17.78 X 17.78 x 81 cm)

Right now I'm putting the base coats of shellac on before I mix in some sparkle blue

pearl-ex powder. Jordan 92s drivers are waiting to go in. I hope the pic uploads.

I'm about to order 2" spikes (5cm). Anyone know if thats about right? Also I'm

getting fiberglass fill as the design allows a shorter line than if polyfill were used.

Has anyone else measured a difference between various fills?

Regards

Lucius

Attachments

fibreglass V plolyester...

in the Loudspeaker design Cookbook, Vance Dickenson lists a comparison (although not specifically for any loudspeaker type.

the key is to use the appropriate amount of "stuffing", and the appropriate type. Speed of sound in long fibre wool is approximately 405'/sec, Dacron and Fibreglass are less good.resulting in higher speeds and less dampening. Wool is more effective and should allow for an even shorter path (that behaves like a longer one) than fibreglass and Dacron.

I am a little out of my element here, but perhaps some of the TL gurus around here can give a better or more rigourous explaination.

in the Loudspeaker design Cookbook, Vance Dickenson lists a comparison (although not specifically for any loudspeaker type.

the key is to use the appropriate amount of "stuffing", and the appropriate type. Speed of sound in long fibre wool is approximately 405'/sec, Dacron and Fibreglass are less good.resulting in higher speeds and less dampening. Wool is more effective and should allow for an even shorter path (that behaves like a longer one) than fibreglass and Dacron.

I am a little out of my element here, but perhaps some of the TL gurus around here can give a better or more rigourous explaination.

Nanook

Later reports are that wool & say accusta stuff, pillow stuff do the same. In the

"Alpha Line" the author reports using fibreglass will allow the same amount of Bass

in a shorter line. I've heard that Wool can attract insects. I don't mind yellow snow

but those damn Canadian black flies drive me crazy.

Lucius

Later reports are that wool & say accusta stuff, pillow stuff do the same. In the

"Alpha Line" the author reports using fibreglass will allow the same amount of Bass

in a shorter line. I've heard that Wool can attract insects. I don't mind yellow snow

but those damn Canadian black flies drive me crazy.

Lucius

Speed of sound in long fibre wool is approximately 405'/sec

405 ft/sec = 123 m/sec which is almost a reduction of a factor of 3 over the speed of sound in air! Where did you get that number? My experience is that the speed of sound in wool, fiber-glass, or Dacron can never get lower than 290 m/sec which represents an adiabatic process. A better estimate would be greater than that value, say 300 - 325 m/sec for theses materials. The damping provided by each would be different and a function of stuffing density.

Black flies and the speed of sound..

I think the last line in my previous post says it all.

The numbers I got for long fibre wool were found within the LDCB , 5th Ed (table 4.2, pg76).

I'll have to dig up the numbers for fibreglass, I know they're in there somewhere (I didn't just pull em outta my a**). The quality of the dampening and amount of stuffing may vary depending on what is being used... unless Accousta-stuff, etc and other "propriatary" materials do not perform as suggested.

As far as being an adiabatic process, Yes, but that assumption (of an adiabatic process) is based on no external influences--a closed system, and usually an ideal gas . Unless you consider venting and the atmosphere making up the closed system, the system should be closed. As far as practical experience, I do not doubt that MJK and others have vastly more to bring to the table, and any advice offered by them (MJK , Bob Brines, etc), should be heeded and followed. Their contributions to the DIY community cannot be over-stated (there are many others too, sorry if I seem to exclude any others)

I am really not trying to re-invent the wheel here. I was intending on just reporting the numbers that I recall reading to answer the question posed.

Never met a black fly that couldn't be tamed and kept as a pet , to be unleashed upon the hordes of 'mericans disturbing the yellow snow or piles of doggie doo doo. ' '

'

I am a little out of my element here, but perhaps some of the TL gurus around here can give a better or more rigourous explaination.

I think the last line in my previous post says it all.

The numbers I got for long fibre wool were found within the LDCB , 5th Ed (table 4.2, pg76).

I'll have to dig up the numbers for fibreglass, I know they're in there somewhere (I didn't just pull em outta my a**). The quality of the dampening and amount of stuffing may vary depending on what is being used... unless Accousta-stuff, etc and other "propriatary" materials do not perform as suggested.

As far as being an adiabatic process, Yes, but that assumption (of an adiabatic process) is based on no external influences--a closed system, and usually an ideal gas . Unless you consider venting and the atmosphere making up the closed system, the system should be closed. As far as practical experience, I do not doubt that MJK and others have vastly more to bring to the table, and any advice offered by them (MJK , Bob Brines, etc), should be heeded and followed. Their contributions to the DIY community cannot be over-stated (there are many others too, sorry if I seem to exclude any others)

I am really not trying to re-invent the wheel here. I was intending on just reporting the numbers that I recall reading to answer the question posed.

Never met a black fly that couldn't be tamed and kept as a pet , to be unleashed upon the hordes of 'mericans disturbing the yellow snow or piles of doggie doo doo. '

'

'The numbers I got for long fibre wool were found within the LDCB , 5th Ed (table 4.2, pg76).

Those values were based on Bradbury's AES paper on fiber damping in TLs. Bradbury is the one who proposed the moving fiber theory which was mathematically very elegant but unfortunately incorrect. Personally, I believe Bradbury missed the tapered geometry influence on the standing wave frequency when he proposed his theory. The more modern approach to TLs no longer includes dramatic reductions in the speed of sound in a fiber filled pipe.

He was fooled by a swarm of Canadian black flies in his woolly fibrous tangle.

"Adiabatic" I think I caught it. The fiber makes the pipe look bigger & like

water in a hose, if its a narrow hose, the water flows fast, a fat hose, the water

flows slow but both the same amount of water.

So originally I should have said..Does using fibreglass in place of wool &

pillow stuffing make the pipe look bigger & therefore you can use a shorter

pipe?

Thanks for the insights,

Lucius

"Adiabatic" I think I caught it. The fiber makes the pipe look bigger & like

water in a hose, if its a narrow hose, the water flows fast, a fat hose, the water

flows slow but both the same amount of water.

So originally I should have said..Does using fibreglass in place of wool &

pillow stuffing make the pipe look bigger & therefore you can use a shorter

pipe?

Thanks for the insights,

Lucius

Greets!

In the Alpha TL article, two different materials are designed around, polyfil and fiberglass insulation, with the fiberglass designs being considerably shorter with less stuffing density, but with a larger cross sectional area (CSA), though net Vb is still close since it's what determines the unstuffed amount of acoustic gain. Not many 'free lunches' in audio.

GM

In the Alpha TL article, two different materials are designed around, polyfil and fiberglass insulation, with the fiberglass designs being considerably shorter with less stuffing density, but with a larger cross sectional area (CSA), though net Vb is still close since it's what determines the unstuffed amount of acoustic gain. Not many 'free lunches' in audio.

GM

Greg, Martin, is is me, or is there something of an analogy here between centrifugal and axiel flow compressors?

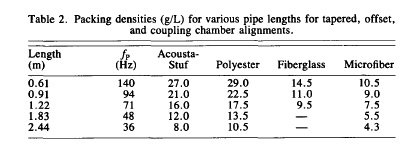

Augsperger's May 2000 AES article gives stuffing densitiies for various materials based on his TL alignments (which are also 'short' TLs). He says there isn't a lot of difference between the end results (and Acoustuff is similar to wool) but fibre glass is unpleasant to work with.

In case it's of use, the table is below.

I'm just completing a pair of JX92S Augsperger lines, so I'll be interested to read how the Alpas turn out.

In case it's of use, the table is below.

I'm just completing a pair of JX92S Augsperger lines, so I'll be interested to read how the Alpas turn out.

Attachments

Augsperger's May 2000 AES article gives stuffing densitiies for various materials based on his TL alignments (which are also 'short' TLs). He says there isn't a lot of difference between the end results (and Acoustuff is similar to wool) but fibre glass is unpleasant to work with.

Thanks Colin

Maybe fibre glass would give the damping effect without smothering the line which

is a problem I've read here. Thanks for Augsperger's table. The micro fibre looks better

if I can find it.

I'd like to here more on your design.

Lucius

Hi Lucius

I used the Augspurger (get the spelling right this time) tables and drew up a spread sheet, then tapped in the JX92S parameters. The coupled cavity table matched the 92 best so I've built a cabinet with a 3 foot line coupled to a 5 litre cavity. It's actually slightly larger in volume than the table recommended. It's got a target cutoff of 65Hz so I'm not expecting great bass. It was a bit of an experiment and I tried something a couple of years back with some Scanspeaks. Not a lot of bass but they worked well, without any boom, when moved into corners.

I'll test them in the next week or so and report back.

I used the Augspurger (get the spelling right this time) tables and drew up a spread sheet, then tapped in the JX92S parameters. The coupled cavity table matched the 92 best so I've built a cabinet with a 3 foot line coupled to a 5 litre cavity. It's actually slightly larger in volume than the table recommended. It's got a target cutoff of 65Hz so I'm not expecting great bass. It was a bit of an experiment and I tried something a couple of years back with some Scanspeaks. Not a lot of bass but they worked well, without any boom, when moved into corners.

I'll test them in the next week or so and report back.

Scottmoose said:Greg, Martin, is is me, or is there something of an analogy here between centrifugal and axiel flow compressors?

Greets!

You lost me.........

GM

My concern of Augsperger's work is that his stuffing densities appear to be rather on the high side. That said, I haven't got access to his full articles -I assume he was going all out for fully damped lines, rather than more resonant ones.

Sorry Greg -I was refering to the fact that centrifugal compressors tend to be shorter and wider (at least in turbojet engines -the Rolls Royce Nene is a good example), whilst axiel flow compressors (Like, say, the RR Avon) are longer and thinner, in reference to the fibreglass and polyfill CSAs / length in the Alpha. Tenuous I admit.

Cheers

Scott

Sorry Greg -I was refering to the fact that centrifugal compressors tend to be shorter and wider (at least in turbojet engines -the Rolls Royce Nene is a good example), whilst axiel flow compressors (Like, say, the RR Avon) are longer and thinner, in reference to the fibreglass and polyfill CSAs / length in the Alpha. Tenuous I admit.

Cheers

Scott

The AES article supposes fully damped lines - his model concentrates on shorter lines to keep efficiency similar to a closed box but with higher power handling at f3. The downside is the lines seem to be tuned around an octave above the driver resonance.

I don't think it would be worth copying the tables here as you need the full article to follow what lies behind them - it's available from the AES website.

I don't think it would be worth copying the tables here as you need the full article to follow what lies behind them - it's available from the AES website.

Greets!

I agree, though it's a good plan for many apps, just not FR driver ones IMO. Like any cab alignment, it's just the proper 'tool' for a range of specific 'jobs'.

No, not tenuous, it's a good mechanical analogy IMO, I just didn't 'get it'. I'm so preoccupied of late that anything that requires much thought is more of a struggle than normal.

GM

I agree, though it's a good plan for many apps, just not FR driver ones IMO. Like any cab alignment, it's just the proper 'tool' for a range of specific 'jobs'.

No, not tenuous, it's a good mechanical analogy IMO, I just didn't 'get it'. I'm so preoccupied of late that anything that requires much thought is more of a struggle than normal.

GM

Hi Greg

Am I right in assuming your doubts about the Augspurger alignments are due to effects higher up the freq range? I assumed the coupled cavity version would have avoided that. I'll find out this weekend when I put the drivers into the cabinets... can always use more bird boxes around the garden if they don't work.

There was a design in 70s by Robert Fis, called the Daline, which had a similar approach. He concentrated on the bass, extending the response of a KEF B110 down to 30Hz or lower. It's an interesting read but I found the article unclear about the design process.

Am I right in assuming your doubts about the Augspurger alignments are due to effects higher up the freq range? I assumed the coupled cavity version would have avoided that. I'll find out this weekend when I put the drivers into the cabinets... can always use more bird boxes around the garden if they don't work.

There was a design in 70s by Robert Fis, called the Daline, which had a similar approach. He concentrated on the bass, extending the response of a KEF B110 down to 30Hz or lower. It's an interesting read but I found the article unclear about the design process.

Greets!

You're losing me, easy to do these days, unfortunately......... 🙁

'Coupled cavity'? I was referring to the high TL stuffing densities his TL alignments require, which 'sucks the life' out of alignments that XO somewhat above the driver's TL BW due to the added acoustic mass damping them, ergo not suitable for FR driver alignments IMO. Below this BW, it only lowers the driver's effective Q, so can be beneficial.

The Daline is an alignment designed to ~adapt the low Fs, Qts drivers required for high output impedance tube sources to the 'brave new world' of low ouput impedance SS sources without wasting all its efficiency and/or adding a sub system or resorting to a huge BLH.

Basically, calc a T/S max flat alignment for a low Fs, Qts driver and you get a relatively tiny cab tuned an octave or more above its Fs, so a large, long vent is required if you want to tune it to near/at its Fs. It's TL modes are problematic, so reverse tapering it is required to shorten it to a bit more manageble length, then stuffing is used to fine tune it in-room, though FWIW, not knowing about Dalines when I was actively building, I followed Altec's 'lead', using a large braced constant CSA duct and critically damping it using the simple 'click' test and my ears as outlined in DIY books of the day.

The results can be impressive, especially if corner loaded, yielding effortless, life-like bass response to the lowest audible limits just like a huge IB, except with more gain, and it will have as good as, or slightly lower, GD in its passband to boot (within the limits of the source and signal chain of course!).

Vented alignments aren't intrinsically poor performers, just usually poorly designed/implemented.

GM

You're losing me, easy to do these days, unfortunately......... 🙁

'Coupled cavity'? I was referring to the high TL stuffing densities his TL alignments require, which 'sucks the life' out of alignments that XO somewhat above the driver's TL BW due to the added acoustic mass damping them, ergo not suitable for FR driver alignments IMO. Below this BW, it only lowers the driver's effective Q, so can be beneficial.

The Daline is an alignment designed to ~adapt the low Fs, Qts drivers required for high output impedance tube sources to the 'brave new world' of low ouput impedance SS sources without wasting all its efficiency and/or adding a sub system or resorting to a huge BLH.

Basically, calc a T/S max flat alignment for a low Fs, Qts driver and you get a relatively tiny cab tuned an octave or more above its Fs, so a large, long vent is required if you want to tune it to near/at its Fs. It's TL modes are problematic, so reverse tapering it is required to shorten it to a bit more manageble length, then stuffing is used to fine tune it in-room, though FWIW, not knowing about Dalines when I was actively building, I followed Altec's 'lead', using a large braced constant CSA duct and critically damping it using the simple 'click' test and my ears as outlined in DIY books of the day.

The results can be impressive, especially if corner loaded, yielding effortless, life-like bass response to the lowest audible limits just like a huge IB, except with more gain, and it will have as good as, or slightly lower, GD in its passband to boot (within the limits of the source and signal chain of course!).

Vented alignments aren't intrinsically poor performers, just usually poorly designed/implemented.

GM

Thanks for that - think I follow it all.

I mentioned coupled cavity as one of the AES alignments is specifically for a coupled cavity/Daline style box. The other two he writes about are reverse taper and offset. I tried the offset with a Jordan array but the result sounded thin compared to a sealed box. I've cheated on the Augspurger CC and made the overall volume and length a little more (so it's my fault if it doesn't work).

I've been meaning to ask - of the various options for the JX92 (both full range and with a bass driver) what would be your favoured way of using it?

I mentioned coupled cavity as one of the AES alignments is specifically for a coupled cavity/Daline style box. The other two he writes about are reverse taper and offset. I tried the offset with a Jordan array but the result sounded thin compared to a sealed box. I've cheated on the Augspurger CC and made the overall volume and length a little more (so it's my fault if it doesn't work).

I've been meaning to ask - of the various options for the JX92 (both full range and with a bass driver) what would be your favoured way of using it?

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- Alpha Line