Hi all,

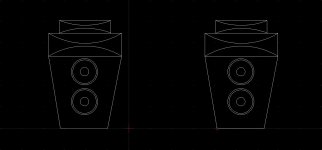

Ready to start bracing a new build looking for some advice.

Cabinet concept is double that of JBL 4646A (single 2206H in 1.2 cu ft enclosure tuned to 60Hz).

Initial target 2.4 cu ft tuned close to 60Hz.

Dimensions 33.5" x 18" x 10.5"

Dual JBL 2206H - covering 75Hz - 600Hz with DSP.

2 x 4" precision ports

Eventually denim insulation lining the cabinet walls once bracing is complete.

Cabinet will be standing tall/vertical side up, rear ports close to bottom, large format horns directly on top.

Last pic is mocked up for some bracing. Looking for some guidance.

2 side

3 length

4 or 5 front/back

Is this sufficient? Too much? Too little?

Look forward to all comments or suggestions.

Ready to start bracing a new build looking for some advice.

Cabinet concept is double that of JBL 4646A (single 2206H in 1.2 cu ft enclosure tuned to 60Hz).

Initial target 2.4 cu ft tuned close to 60Hz.

Dimensions 33.5" x 18" x 10.5"

Dual JBL 2206H - covering 75Hz - 600Hz with DSP.

2 x 4" precision ports

Eventually denim insulation lining the cabinet walls once bracing is complete.

Cabinet will be standing tall/vertical side up, rear ports close to bottom, large format horns directly on top.

Last pic is mocked up for some bracing. Looking for some guidance.

2 side

3 length

4 or 5 front/back

Is this sufficient? Too much? Too little?

Look forward to all comments or suggestions.

Attachments

Last edited:

Run braces the long way. I also like to uise them to brace the drivers to more walls to share the reactive forces.

dave

dave

Thanks Dave.

Would 3 braces running long way be better approach? The ports are huge, need to work around them that way.

I remember watching video of someone disassembling a SVS subwoofer. The magnet fit directly into a circular brace with some type of foam or rubber trim for a snug fit.

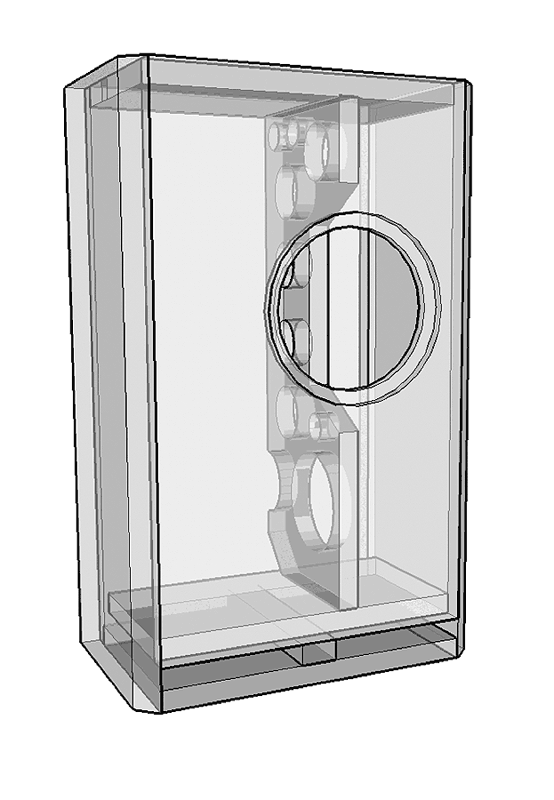

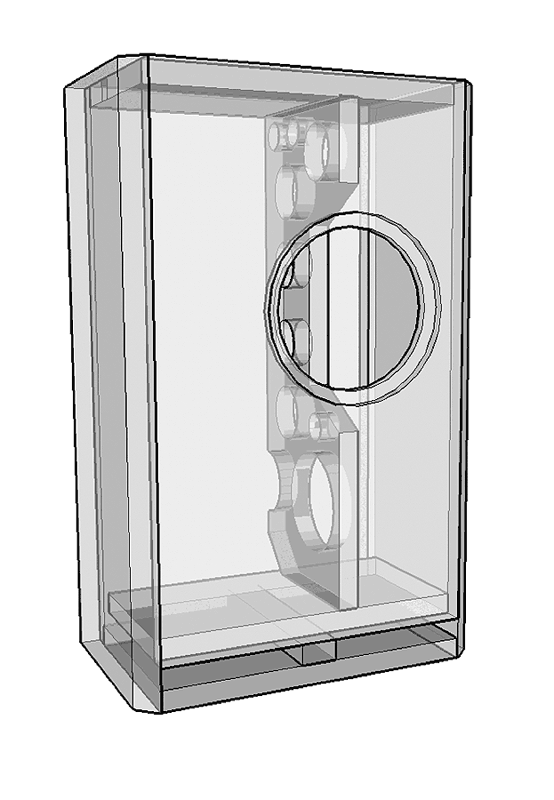

How about this pic?

3 length

2 sides glued to each length

I've never measured the effects of different bracing to know what is gained or lost. I do want to put some effort into this but don't have the ability to make highly detailed interlocking CNC braces. Working with a jigsaw and table saw here.

Would 3 braces running long way be better approach? The ports are huge, need to work around them that way.

Trying to visualize this ... do you mean an actual brace that fits firmly around the entire magnet or basket?I also like to uise them to brace the drivers to more walls to share the reactive forces.

I remember watching video of someone disassembling a SVS subwoofer. The magnet fit directly into a circular brace with some type of foam or rubber trim for a snug fit.

How about this pic?

3 length

2 sides glued to each length

I've never measured the effects of different bracing to know what is gained or lost. I do want to put some effort into this but don't have the ability to make highly detailed interlocking CNC braces. Working with a jigsaw and table saw here.

Attachments

Here is a picture (a push-push pr).

Here one woofer is pushing against the other, the way you have yours configured it would be speaker vrs back.

If your woofers required bandwidth does not need to etend that far up, arranging 2 woofers push-push has significant benefits.

Here is a visual of a small box with one brace:

Your box is about 68 litres, similar size to the big box in the A26ReViz document. https://frugal-phile.com/boxlib/A26-ReViz-0v90-080323.pdf

dave

Here one woofer is pushing against the other, the way you have yours configured it would be speaker vrs back.

If your woofers required bandwidth does not need to etend that far up, arranging 2 woofers push-push has significant benefits.

Here is a visual of a small box with one brace:

Your box is about 68 litres, similar size to the big box in the A26ReViz document. https://frugal-phile.com/boxlib/A26-ReViz-0v90-080323.pdf

dave

Whatcha running for horn/compression driver up top ?

I've been itching to run a double 12 / horn for a while now.................

With .32 qts / 52hz Fs / 2.2ft3

I get 1ft3 tune to 63hz and f3 of 73hz............

or slightly bigger ported butterworth of 1.25ft3 tune to 60.9hz and f3 of 66.64hz

I've been itching to run a double 12 / horn for a while now.................

With .32 qts / 52hz Fs / 2.2ft3

I get 1ft3 tune to 63hz and f3 of 73hz............

or slightly bigger ported butterworth of 1.25ft3 tune to 60.9hz and f3 of 66.64hz

| butterworth Ported equations |

| Vb = qts^2.87 x 15 x Vas |

| F3 = qts^ -1.4 x .26 x fs |

| Fb (tuning) = qts^ -.9 x 0.42 x fs |

Last edited:

Thanks Dave! This is good reference material. The attached pictures, cutsheets and weblink are perfect. The bracing is next level.

The idea was to use 2" bracing strips throughout but no reason why I can't cut the braces full depth as shown then drill out holes using different hole saw bits. Don't think I can incorporate as much bracing as your example but it'll be considerably more than my initial approach.

I want to try and brace the drivers this way too.

The idea was to use 2" bracing strips throughout but no reason why I can't cut the braces full depth as shown then drill out holes using different hole saw bits. Don't think I can incorporate as much bracing as your example but it'll be considerably more than my initial approach.

I want to try and brace the drivers this way too.

I've been buying upgrades for a while, this year its going to (slowly) come together.Whatcha running for horn/compression driver up top ?

First pic is going to morph into second pic. All through quality DSP (VTC 4080DLMS - Canadian rebranded Xilica XP4080) and 4 x Yorkville amps.

2 x 18" VBSS (20Hz - 75Hz) hopefully upgrading to 3 x JBL 4645c spread out through the room.

1 x 2206H (75Hz - 600Hz) upgrading to dual 2206H with wide "faux" baffle

1 x Community M200 on 33" wide Community BRH90 radial (600Hz - 3kHz) no change, I've yet to hear better 2" midrange driver.

1 x Community VHF100 on 25" wide Community RH90 radial - (3kHz - Up) upgrading from RCF ND350 - no comparison the VHF100 is a unicorn of a driver.

@norman bates Allow me to have a Saturday morning coffee fanboy moment... There is something noticeably different about the Community drivers, I recall us reminiscing about DJK's (RIP brother) valuable advice in an older thread. They are heart of this system. Both very low compression ratio's and extremely low distortion. DJK claimed you'd be hard pressed to tell the difference between them vs TAD drivers. People he upgraded to Community drivers never turned back. I understand why. They are satisfying, never experience listening fatigue like other drivers I've owned. A pile of VHF100 showed up on ebay recently, expensive IMO but I've been waiting for years for an opportunity to buy them. Thankfully they measured excellent and weren't abused. I need to baby them now because diaphragms are no longer available.

The VHF100 is the only 1" driver I've ever had to attenuate above 7kHz with a high shelf. It's so clean on the high end I had to learn how to listen again. The difference from other 1" drivers is not subtle. I would love for someone like Joseph (Troy) Crowe to do his full measurement analysis of these Community drivers because I don't have the technical knowledge to explain why they sound so pleasing. Bruce Howze is underrated. Guy developed some awesome horns and drivers.

Attachments

Last edited:

Paging @planet10 or anyone who can offer their expert insight.

I did a mock up of the middle brace with some of my daughters arts and craft paper.

The 2206's have 3 vents on the back, in an effort not to block them I'm trying to support the back of the magnet instead.

Leaving a tiny gap above the vents.

If this makes sense I'll do the same on either side of each woofer.

Thoughts?

I did a mock up of the middle brace with some of my daughters arts and craft paper.

The 2206's have 3 vents on the back, in an effort not to block them I'm trying to support the back of the magnet instead.

Leaving a tiny gap above the vents.

If this makes sense I'll do the same on either side of each woofer.

Thoughts?

Attachments

A long as you get the contact with the driver just right, not loose, but not so tight to put stress on the basket.

dave

dave

Ok, thanks. I appreciate your guidance here.

Thinking of leaving the drivers screwed in place when clamping these braces to ensure 100% contact.

Would it be fine to apply some firm pressure against the basket? Or is this a bad idea?

I have standard workouts weights, circular individual plates 5lbs, 10lbs, 25lbs, 45lbs.

Thinking of leaving the drivers screwed in place when clamping these braces to ensure 100% contact.

Would it be fine to apply some firm pressure against the basket? Or is this a bad idea?

I have standard workouts weights, circular individual plates 5lbs, 10lbs, 25lbs, 45lbs.

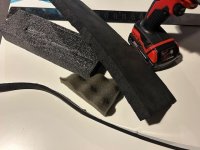

Thanks @Arez, it did cross my mind. Maybe need to find the right material for the job.

I have various materials discarded from work used for packing Telecommunications equipment. Many types of foam and rubber, see pics.

I found Penn ultra-blue raquetballs work amazing for vibrations/isolation, see last pic. Cut them in half like dome isolators. These were the only effective material that seem to isolate my turntables from subsonic basslines when listening at extreme loud levels. Not sure it would be effective when bracing but I could cut them into small strips and use as a buffer between magnet and brace. No issues trying something new and no issues with failing miserably. I tend to learn best the hard way. Trial and error. Obviously people prefer one attempt and done but my DIY experience has been full of mistakes and steep learning curves.

How hot do the magnets actually get if I go full power for small 10 minutes intervals? Hot enough to melt rubber?

I typically listen around 90dB but do crank it up over 100dB because I like to feel the room "breathing" for certain tunes. There is heavy acoustic treatment in my unfinished basement. Its my personal lab, mancave, hobby room whatever you want to call it. It is dedicated to listening, when the wife and daughter are away .... playback tends to get very loud.

I have various materials discarded from work used for packing Telecommunications equipment. Many types of foam and rubber, see pics.

I found Penn ultra-blue raquetballs work amazing for vibrations/isolation, see last pic. Cut them in half like dome isolators. These were the only effective material that seem to isolate my turntables from subsonic basslines when listening at extreme loud levels. Not sure it would be effective when bracing but I could cut them into small strips and use as a buffer between magnet and brace. No issues trying something new and no issues with failing miserably. I tend to learn best the hard way. Trial and error. Obviously people prefer one attempt and done but my DIY experience has been full of mistakes and steep learning curves.

How hot do the magnets actually get if I go full power for small 10 minutes intervals? Hot enough to melt rubber?

I typically listen around 90dB but do crank it up over 100dB because I like to feel the room "breathing" for certain tunes. There is heavy acoustic treatment in my unfinished basement. Its my personal lab, mancave, hobby room whatever you want to call it. It is dedicated to listening, when the wife and daughter are away .... playback tends to get very loud.

Attachments

Ok, I hear you.solid contact, but non stress, it is tricky.

Chris always temorarily fixed the drivers while he got the brace just right.

Yeah, can't imagine fitting the brace into position behind the magnet without the drivers in place.

Time to give it a go.

Appreciate the advice. Thanks.

Hello AE13 !

Personally, I try as much as possible to avoid breaking the rear waves of the boomers. Here's an example:

with MDF reinforcements openwork to "cushion" the rear wave near the speakers and a volume frame made of pine strips to reinforce and cushion as well.

Bye !

Laurent

Personally, I try as much as possible to avoid breaking the rear waves of the boomers. Here's an example:

with MDF reinforcements openwork to "cushion" the rear wave near the speakers and a volume frame made of pine strips to reinforce and cushion as well.

Bye !

Laurent

- Home

- Loudspeakers

- Multi-Way

- Advice on bracing this ported enclosure ...