Hello community,

I am new member here although I visited this site anonymously many times in the past. Thank you for many useful information, tips and tricks and all 🙂

In the past, I built several loudspeakers following known designs. Recently I decided to build Visaton's Clou. It is almost finished but I am having trouble with one of the SC 10 Ns.

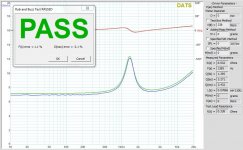

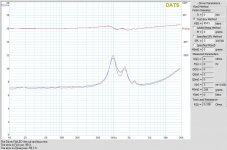

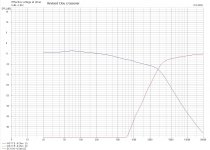

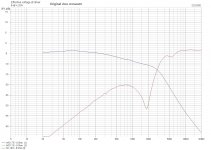

I use Dayton Audio DATS V2 to test and measure all my drivers before installing them. I tested about a dozen of Visaton drivers so far but the SC 10 N showed anomalies I did not like - it had triple impedance peaks and did not pass the DATS rub and buzz test. I returned that faulty SC 10 N to the seller and they exchanged it for another specimen which had similar issues. (The "good" SC 10 N I have measures just fine on DATS and passes the rub and buzz test.)

I also talked to Visaton people and one of their technicians suggested I should excite the transducer with a 4 Volts sine tone at drivers resonant frequency (~1500 Hz -to evenly distribute ferrofluid - alleged culprit of the issue). I did that and here is the summary of that experiment:

-Exciting the transducer with sine wave at frequencies at or near its F(s) eliminates most anomalous impedance peaks 🙂

-However, the same transducer subsequently excited with signals carrying other frequencies (including plain music) goes back to its faulty state 🙁

I reported these results back to Visaton and last they said is that those multiple peaks "are not critical" for normal operation. I hear some difference and I also used ARTA and REW to verify my suspicion; the curves for my good SC 10 N and the bad ones are somewhat different. (However, I still do not have a calibrated mic.)

I also do not have experience with problems of this kind and the SC 10 N is sealed so I do not want to temper with it and void the warranty.

Please advise, thanks.

I am new member here although I visited this site anonymously many times in the past. Thank you for many useful information, tips and tricks and all 🙂

In the past, I built several loudspeakers following known designs. Recently I decided to build Visaton's Clou. It is almost finished but I am having trouble with one of the SC 10 Ns.

I use Dayton Audio DATS V2 to test and measure all my drivers before installing them. I tested about a dozen of Visaton drivers so far but the SC 10 N showed anomalies I did not like - it had triple impedance peaks and did not pass the DATS rub and buzz test. I returned that faulty SC 10 N to the seller and they exchanged it for another specimen which had similar issues. (The "good" SC 10 N I have measures just fine on DATS and passes the rub and buzz test.)

I also talked to Visaton people and one of their technicians suggested I should excite the transducer with a 4 Volts sine tone at drivers resonant frequency (~1500 Hz -to evenly distribute ferrofluid - alleged culprit of the issue). I did that and here is the summary of that experiment:

-Exciting the transducer with sine wave at frequencies at or near its F(s) eliminates most anomalous impedance peaks 🙂

-However, the same transducer subsequently excited with signals carrying other frequencies (including plain music) goes back to its faulty state 🙁

I reported these results back to Visaton and last they said is that those multiple peaks "are not critical" for normal operation. I hear some difference and I also used ARTA and REW to verify my suspicion; the curves for my good SC 10 N and the bad ones are somewhat different. (However, I still do not have a calibrated mic.)

I also do not have experience with problems of this kind and the SC 10 N is sealed so I do not want to temper with it and void the warranty.

Please advise, thanks.

Attachments

If the driver failed rub and buzz tests I would return the unit.

This is easier found out with a woofer, (no need for DATS to tell me its rubbing).

I would return any 'bad' units, with the fault description of "coil rub", no other explanation.

By engaging in this way, the company advice to redistribute ferrofluid, that's frankly avoiding the issue.

"Within nominal production tolerances" would be a similar remark.

Just return, and ask for replacement, until you have enough drivers that are satisfactory.

Dont expect to be receiving a matched pair, tolerances are probably +/-20%.

I'd be especially careful but it's possible the magnet and faceplate are slightly misaligned- shipping and handling can knock the VC off centre - it possible to improve or worsen rubs by loosening or tightening faceplate screws (in general, not specifically this tweeter, also I can't see fixings so it may have none).

I once had some Audax tweeters that had marked THD until I undid the faceplate screws, pulled the diaphragm and voice coil out, turned 180deg and assembled again.

Oh and lastly, there is no warranty to void.

This is easier found out with a woofer, (no need for DATS to tell me its rubbing).

I would return any 'bad' units, with the fault description of "coil rub", no other explanation.

By engaging in this way, the company advice to redistribute ferrofluid, that's frankly avoiding the issue.

"Within nominal production tolerances" would be a similar remark.

Just return, and ask for replacement, until you have enough drivers that are satisfactory.

Dont expect to be receiving a matched pair, tolerances are probably +/-20%.

I'd be especially careful but it's possible the magnet and faceplate are slightly misaligned- shipping and handling can knock the VC off centre - it possible to improve or worsen rubs by loosening or tightening faceplate screws (in general, not specifically this tweeter, also I can't see fixings so it may have none).

I once had some Audax tweeters that had marked THD until I undid the faceplate screws, pulled the diaphragm and voice coil out, turned 180deg and assembled again.

Oh and lastly, there is no warranty to void.

Last edited:

Thank you mondogenerator 🙂 I needed expert opinion to back me up.

I'll post the results of my SC 10 N adventure when it ends.

I guess I was lucky with the other drivers for the Clou (four WS 17 Es) as they measured pretty close, 1-3 Hz difference between their F(s) and few minor points difference between Q(es), Q(ms) and Q(ts). As the manufacturers usually declare 15% tolerance on their drivers' parameters I'll be OK with that too. Clou is not a high end anyway.

Thanks again, have a good day 🙂

I'll post the results of my SC 10 N adventure when it ends.

I guess I was lucky with the other drivers for the Clou (four WS 17 Es) as they measured pretty close, 1-3 Hz difference between their F(s) and few minor points difference between Q(es), Q(ms) and Q(ts). As the manufacturers usually declare 15% tolerance on their drivers' parameters I'll be OK with that too. Clou is not a high end anyway.

Thanks again, have a good day 🙂

Time is passing by too quickly for me but that is no excuse for not posting the update earlier…

I got my second good tweeter for the Clou and it was a very close match to the other, lucky me. This is thanks to the local distributor (Conrad.ba). Visaton people were not helpful, I communicated with two of them. One kept on saying things like: “…it cannot be controlled… it is not critical for performance” etc. and the other representative said “we cannot help you because we do not sell directly to your country”. Well, ok, thank you, goodbye, nevermore.

Anyhow, the Clou is finished and I am pleased with them. I am not going to write comments here about how they sound because I agree with the reviews posted on Visaton's page.

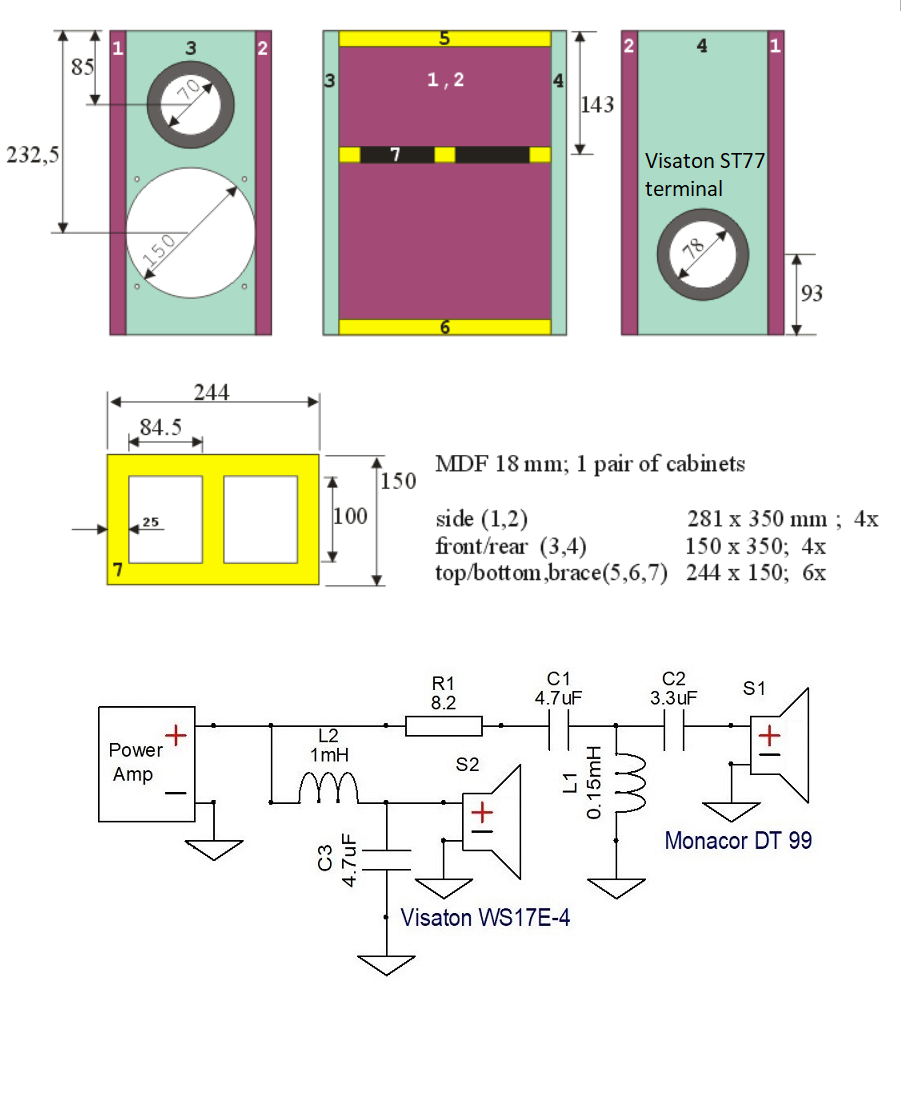

Compared to the original design and construction instructions I made a few small changes:

- used 18mm MDF instead of 16mm

- put three reinforcers instead of one

- chamfered back of the driver openings

- used pillow PE stuffing and some Acousta stuff surplus from another project instead of Visaton PE wool mats

- beveled top edge (should have used a bigger router bit on it and on the side edges as well)

Finish is oak veneer, few layers of water based oak lazure and on top of that clear yacht varnish. Not tested if the enclosures are now seaworthy, haha. (But they very well should be.)

All in all, not perfect but good enough…

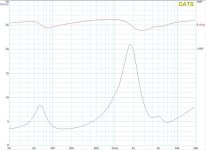

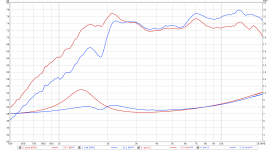

Photos attached. Impedance and phase angle measured and look good. Acoustic measurement? Did it but need better equipment and more practice to get consistent results. And not to be lazy.

After the Clous I completed 2-3 other projects, will post soon.

Have a good day 🙂

I got my second good tweeter for the Clou and it was a very close match to the other, lucky me. This is thanks to the local distributor (Conrad.ba). Visaton people were not helpful, I communicated with two of them. One kept on saying things like: “…it cannot be controlled… it is not critical for performance” etc. and the other representative said “we cannot help you because we do not sell directly to your country”. Well, ok, thank you, goodbye, nevermore.

Anyhow, the Clou is finished and I am pleased with them. I am not going to write comments here about how they sound because I agree with the reviews posted on Visaton's page.

Compared to the original design and construction instructions I made a few small changes:

- used 18mm MDF instead of 16mm

- put three reinforcers instead of one

- chamfered back of the driver openings

- used pillow PE stuffing and some Acousta stuff surplus from another project instead of Visaton PE wool mats

- beveled top edge (should have used a bigger router bit on it and on the side edges as well)

Finish is oak veneer, few layers of water based oak lazure and on top of that clear yacht varnish. Not tested if the enclosures are now seaworthy, haha. (But they very well should be.)

All in all, not perfect but good enough…

Photos attached. Impedance and phase angle measured and look good. Acoustic measurement? Did it but need better equipment and more practice to get consistent results. And not to be lazy.

After the Clous I completed 2-3 other projects, will post soon.

Have a good day 🙂

Attachments

Lovely project, Alipos. Wish I could do woodwork! 😀

We like the the W17E!

Visaton-Monacor 2 way sealed simple loudspeaker build plans

Original Clou:

CLOU | Visaton

I'd get modelling:

Software | Visaton

Put this file in the projekte folder:

Clou – Boxsim Projektdatenbank

I think the crossover could be better. Third order tweeter. But closed box is right.

We like the the W17E!

Visaton-Monacor 2 way sealed simple loudspeaker build plans

Original Clou:

CLOU | Visaton

I'd get modelling:

Software | Visaton

Put this file in the projekte folder:

Clou – Boxsim Projektdatenbank

I think the crossover could be better. Third order tweeter. But closed box is right.

Last edited:

Hey system7, thanks for the comments!

I did see Lojzek’s project before and as it happens I made something similar with that Visaton midbass and a Dayton Audio tweeter. Will post it later.

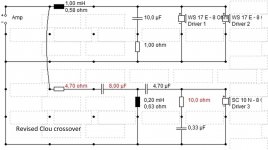

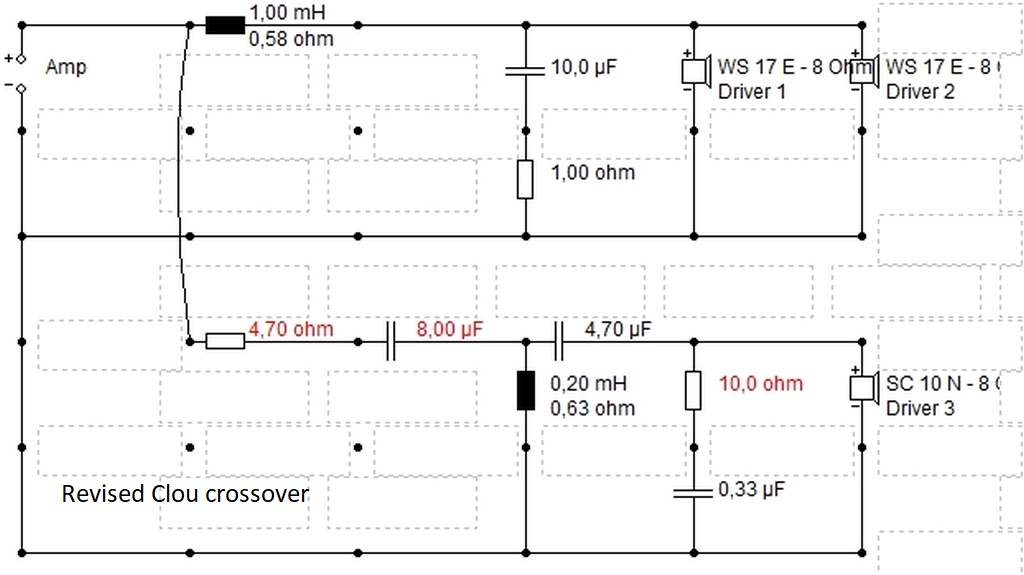

About the Clou crossover... I had questions about the original one, especially the look of the frequency/electrical response for the tweeter so I modeled other versions in Boxsim and tested the one from the attached files. The overall sound was more... relaxed. However, at the end I used the original version because I had it assembled and on forums I looked people said like “leave it as it is, Visaton knows what they are doing”.

Cheers!

I did see Lojzek’s project before and as it happens I made something similar with that Visaton midbass and a Dayton Audio tweeter. Will post it later.

About the Clou crossover... I had questions about the original one, especially the look of the frequency/electrical response for the tweeter so I modeled other versions in Boxsim and tested the one from the attached files. The overall sound was more... relaxed. However, at the end I used the original version because I had it assembled and on forums I looked people said like “leave it as it is, Visaton knows what they are doing”.

Cheers!

Attachments

Having superbly built this TMM, I would persist with this crossover:

Except the two tweeter capacitors are in the wrong order. Swap them round. 🙂

I detest parallel MTM or TMM on principle. 4 ohms gives amps a hard time.

Wire them in series. Then add an LCR notch around 500Hz. Takes away a bit of shout in the voices. Making for a great speaker.

Mr Troels Gravesen, who knows this territory usually uses an LCR notch:

DIY-Loudspeakers

But what do I know?

Except the two tweeter capacitors are in the wrong order. Swap them round. 🙂

I detest parallel MTM or TMM on principle. 4 ohms gives amps a hard time.

Wire them in series. Then add an LCR notch around 500Hz. Takes away a bit of shout in the voices. Making for a great speaker.

Mr Troels Gravesen, who knows this territory usually uses an LCR notch:

DIY-Loudspeakers

But what do I know?

Thank you for all the comments, tips and links 🙂

I consider the Clou project completed for now.

Perhaps in the future, if I get "inspired", I will change its crossover.

Before that, I would like to build a nice 3-way 😉

I consider the Clou project completed for now.

Perhaps in the future, if I get "inspired", I will change its crossover.

Before that, I would like to build a nice 3-way 😉

I measured my old SC 10 N tweeters. I didn't use them for probably more than 10 years.

One has similar issue. It also has a lot of distortion. It must be rubbing or something with ferrofluid. It could be it was bad as new.

Anyway I stored them back in closed.

One has similar issue. It also has a lot of distortion. It must be rubbing or something with ferrofluid. It could be it was bad as new.

Anyway I stored them back in closed.

Attachments

- Home

- Loudspeakers

- Multi-Way

- Advice needed for Visaton SC 10 N problem