VEC7OR said:

😀 😀 😀

Profanity took a very interesting form in Russia where there exists a language of sorts, most of its words based on four basic profane roots - nouns p...is, wh.0.e, c..t and verb f..k. It is possible to sensibly communicate using just these four basic roots.

Its even true...ive heard russians communicating like this 😀

Blin..blad..blin...and so forth.....the less educated russians usually stick to blin...blin...blin...blin 🙂

No offence, but it sure sounds funny 😀

Magura

Concerns

1) Cone

large size. Low frequency of cone modes?

2) Suspension requirements!

assuming particurly 2) being satisfactroy

=

🙂

🙂

you could lose an eye with that thing flying back and forth!

just what i needed.!

But it still isnt a real woofer yet.

When i see t/s specs of the woofer,well see 😀

IT better not be a crap large speaker like the other rip offf designs

the 32" clarion..the other underdamped large woofers

even the fostex800, no (-not much ) electrical damping

-i dont imagine it would be,but $$$$ can be risky with limited number products?

🙂

1) Cone

large size. Low frequency of cone modes?

2) Suspension requirements!

assuming particurly 2) being satisfactroy

=

🙂

🙂 you could lose an eye with that thing flying back and forth!

just what i needed.!

But it still isnt a real woofer yet.

When i see t/s specs of the woofer,well see 😀

IT better not be a crap large speaker like the other rip offf designs

the 32" clarion..the other underdamped large woofers

even the fostex800, no (-not much ) electrical damping

-i dont imagine it would be,but $$$$ can be risky with limited number products?

🙂

121db anechoic and i dont have to build a box, just have it siting on the floor!!!! even if it sounded average you could just have it crossed at 30Hz so that it then takes care of EVERYTHING below there 😀

Drooling will get you know where

I think it's time to quit drooling and time to start deducing the construction of the beast. This is a diy site after all. And the machining is simple as pie. Are you up for it???

Mark

I think it's time to quit drooling and time to start deducing the construction of the beast. This is a diy site after all. And the machining is simple as pie. Are you up for it???

Mark

Looks kind of interesting, but I'll bet you can't put it near a TV, and with 12 inches of xmax, I definitely wouldn't want to make a front-firing woofer out of it, lest the suspension should give way and you have a 30-inch woofer flying at your face. What material could they possibly make a cone (and suspension) out of that could withstand such high excursions at even 30Hz without being ripped apart? I don't see any good use for it, and I think it has a potential to actually be dangerous, and not just to your ears.

they didnt mention efficiency? didnt see it.. quad 2ohm coils is it/

so u need four abnormally low ohm load amps -well thats just GREAT!

wire it in series? ugh! what a waste...

parallel all the way..

dont bother thinking about how it works unless you enjoy FEA and hysteresis loops and advanced mag theory.I think it's time to quit drooling and time to start deducing the construction of the beast.

see the guy at HOMETHEATRE FORUM he analsed the xbl2 by adire.got quite close

Bunch of Chicken arm Chair Quarterbacks

OK enough condemnation. Lets see if I can stir the pot a little.

Question #1 Who in their right mind that frequents this forum would not want one of these???????

Silence of the crickets is deafening.

OK my Notes and musings on the beasts.

3" diameter core is actuallly a little less. DUh

.750 vent

16 columns at .875"

top plate .500"

Back plate .750"

OD 8.75

Height 7.125

1008 steel

if overall height= 7.125 then top plate minus back plate = 5.875"

from scalling the pictures I came up with a magnet height of .750"

from the same scaling of another one of the pictures I came up with 5.125 for actual height for the longer columns. the middle plate has to be joined to the center core for magnetic paths and because in the photos there is a clear shadow beneath it showing that it is a one piece turning.

For magnet sources I came up with:

www.kjmagnetics.com/ZR5.html

and better ( ie cheaper )

www.engconcepts.net/Magnets/Pages/Ring_Magnets.htm

I acknowledge that there are more measurements to be had such as the spacing of the bolt holes but that is childs play. 360/8 = 40 degree equal spacing for the outside. The internal opening for the voice coil is one that can be scaled out to a degree and the voice coil itself will determine most of it. Then we have the questions of how many layers, inside wind, outside or most probalbly both in and out side windings. Former type might be kapton or black anodised aluminum. The harder points for he diy guy is the spiders. Yes there must be multiple spiders on some thing with this much x-max. And the surround must be made as well. But for that see the second last audio Xpress for ideas on that.

So I'mm a pushing anyone else game to do some armchair engineering???

I have access to facilities to machine such a beast and have most of the metal allready. Want to go for it??????

Mark

OK enough condemnation. Lets see if I can stir the pot a little.

Question #1 Who in their right mind that frequents this forum would not want one of these???????

Silence of the crickets is deafening.

OK my Notes and musings on the beasts.

3" diameter core is actuallly a little less. DUh

.750 vent

16 columns at .875"

top plate .500"

Back plate .750"

OD 8.75

Height 7.125

1008 steel

if overall height= 7.125 then top plate minus back plate = 5.875"

from scalling the pictures I came up with a magnet height of .750"

from the same scaling of another one of the pictures I came up with 5.125 for actual height for the longer columns. the middle plate has to be joined to the center core for magnetic paths and because in the photos there is a clear shadow beneath it showing that it is a one piece turning.

For magnet sources I came up with:

www.kjmagnetics.com/ZR5.html

and better ( ie cheaper )

www.engconcepts.net/Magnets/Pages/Ring_Magnets.htm

I acknowledge that there are more measurements to be had such as the spacing of the bolt holes but that is childs play. 360/8 = 40 degree equal spacing for the outside. The internal opening for the voice coil is one that can be scaled out to a degree and the voice coil itself will determine most of it. Then we have the questions of how many layers, inside wind, outside or most probalbly both in and out side windings. Former type might be kapton or black anodised aluminum. The harder points for he diy guy is the spiders. Yes there must be multiple spiders on some thing with this much x-max. And the surround must be made as well. But for that see the second last audio Xpress for ideas on that.

So I'mm a pushing anyone else game to do some armchair engineering???

I have access to facilities to machine such a beast and have most of the metal allready. Want to go for it??????

Mark

see the guy at HOMETHEATRE FORUM he analsed the xbl2 by adire.got quite close

Thanks for noticing. 'Twas I. At your service...😎

So I'mm a pushing anyone else game to do some armchair engineering???

Ok. If you can supply the machining, I can supply the FEA-optimized motor design. (Actually, I already have a couple designs, complete with unique suspension, but I can't share until my patent apps are submitted.)

What I am willing to do, though, is supply a more standard design approach, much like the Parthenon.

However, I propose that we set out with the goal not to clone the Parthenon, but to improve upon it. 🙂 For starters, I suggest we move beyond the Parthenon's twin gaps on a 3" dia. pole, and do a three-gapper on a 4" pole. This will let us either a) build it for more excursion 😱 or b) use a shorter coil stack for greater efficiency/lower Le.

So, you ready Mark? 😀

Hi bill its michael-E form the HT forum here..

i was wondering do you know of any online sites that show diagrams and information about the magnetic circuits and flux densities etc in speaker magnets??

i had a book out of the library that started delving into it,but was only a few pages.and basicaly all i remember was that saturation is good.. lol! it went into very basic issues such as overhung,underhung,but gave a babyish explanation

So any links around??? its very specialised..

i was wondering do you know of any online sites that show diagrams and information about the magnetic circuits and flux densities etc in speaker magnets??

i had a book out of the library that started delving into it,but was only a few pages.and basicaly all i remember was that saturation is good.. lol! it went into very basic issues such as overhung,underhung,but gave a babyish explanation

So any links around??? its very specialised..

Time to knock heads

OK Bill lets see what the two of us can come up with. I've built drivers from the motor up before. The suspension is one of the harder parts. The cone is not that hard. The surround is the easiest part of the bunch. The basket could be made of engineered wood without to much trouble. Now what are your ideas???

Mark

OK Bill lets see what the two of us can come up with. I've built drivers from the motor up before. The suspension is one of the harder parts. The cone is not that hard. The surround is the easiest part of the bunch. The basket could be made of engineered wood without to much trouble. Now what are your ideas???

Mark

This is getting good . A four in VC is a must. 3" just seems a little too small for a piston like that. Even the JBL 2206 has a 4" VC, and that doesn't have excursion enywhere near what is being attempted here.

. A four in VC is a must. 3" just seems a little too small for a piston like that. Even the JBL 2206 has a 4" VC, and that doesn't have excursion enywhere near what is being attempted here.

Cheers,

Zach

. A four in VC is a must. 3" just seems a little too small for a piston like that. Even the JBL 2206 has a 4" VC, and that doesn't have excursion enywhere near what is being attempted here.

. A four in VC is a must. 3" just seems a little too small for a piston like that. Even the JBL 2206 has a 4" VC, and that doesn't have excursion enywhere near what is being attempted here.Cheers,

Zach

I've found the hardest part to be winding the voice coil so far (without the right tools). If anyone can offer an accurate DIY coil winding method, that would be a great help! And how do you plan on making a cone?The suspension is one of the harder parts. The cone is not that hard. The surround is the easiest part of the bunch. The basket could be made of engineered wood without to much trouble. Now what are your ideas???

Revenge of the Cone Heads

Vikash I think I remember your cone and motor structure. You were trying to get a high efficiency full range???

This monster would need a stiff cone. l would probably make it out of an extruded foam. Fancy name for extruded not beaded styrofoam. It's light and relatively stiff. And fairly easy to machine with a hot wire. I have a couple of big variacs and could rig up something in a pinch. As for a voice coil it is no picnic. Ihave rwound them, repaired them and read articles in books and voice coil as to how to make them. As with all things a lot of thought and some research then ingenuity and then musckle power.

With a voice coil the size that Bill mentioned the wire diameter can be a little bigger to. A turning jig between two centers is where I would start. You would need a mandrel to support the former and a guide like that on an old time fishing reel to lay the wire with some control. A days worth of fooling around just to jig up the thing and I think at least a two or three day off and on period of fooling with the wire before it would look like something useable. as for a former I have an inside track on data for voice coils. There are well engineered tables available from coil suppliers that provide most of the leg work. No use reinventing a wheel that is allready rolling. A cone that is thin and light would be cool. I always wanted to try metal spinning and I do have a large capacity wood lathe. Maybe that would be a route to go. The biggest thing that is needed is TIME. AH what we could pull off if we had enough time!!!!!

OK enough babbling. Hows your project coming along vikash?

Mark

Vikash I think I remember your cone and motor structure. You were trying to get a high efficiency full range???

This monster would need a stiff cone. l would probably make it out of an extruded foam. Fancy name for extruded not beaded styrofoam. It's light and relatively stiff. And fairly easy to machine with a hot wire. I have a couple of big variacs and could rig up something in a pinch. As for a voice coil it is no picnic. Ihave rwound them, repaired them and read articles in books and voice coil as to how to make them. As with all things a lot of thought and some research then ingenuity and then musckle power.

With a voice coil the size that Bill mentioned the wire diameter can be a little bigger to. A turning jig between two centers is where I would start. You would need a mandrel to support the former and a guide like that on an old time fishing reel to lay the wire with some control. A days worth of fooling around just to jig up the thing and I think at least a two or three day off and on period of fooling with the wire before it would look like something useable. as for a former I have an inside track on data for voice coils. There are well engineered tables available from coil suppliers that provide most of the leg work. No use reinventing a wheel that is allready rolling. A cone that is thin and light would be cool. I always wanted to try metal spinning and I do have a large capacity wood lathe. Maybe that would be a route to go. The biggest thing that is needed is TIME. AH what we could pull off if we had enough time!!!!!

OK enough babbling. Hows your project coming along vikash?

Mark

My goals weren't as high as that...I was/am aiming for a simple midrange to begin with. The whole project is more a reason to getting some experience with the various parts of a transducer. Once I realised my motor's shortcomings (after playing with femm and learning many things from Bill F and others) things have kinda slowed down (until the metal lathe arrives hopefully). But I've been thinking about how to make a winding jig. I've seen one simple idea that uses an old manual drill to turn the former which is something I was going attempt. Needless to say, I'm very interested in your ideas for coil winding because this has been the main showstopper for me (and coil winding machines are ridiculously priced!)

I still want to use electro-magnetic-suspension, so this just adds to the complexity of the coil winding.

Anyway, another thread jacking is taking place and our ideas may better be collated in a new thread where we can discuss ideas since there is clearly a bunch of us interested in designing a transducer from the ground up...

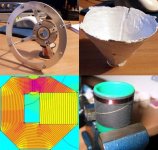

And since we all love pics...

I still want to use electro-magnetic-suspension, so this just adds to the complexity of the coil winding.

Anyway, another thread jacking is taking place and our ideas may better be collated in a new thread where we can discuss ideas since there is clearly a bunch of us interested in designing a transducer from the ground up...

And since we all love pics...

Attachments

SkinnyBoy said:I have no idea what anyones talking about.... lol but I want a big subwoofer.. 😀😀

😀

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Adire Audio's new motor (Parthenon)