Yes, the raspberry pi is tinker friendly.

Have been reading about small form factor computers a lot, even purchased the cubox 4 pro or what's it called, a few years back. It's not powerful enough for my needs.

Maybe in 5 years the latest and greatest rpi or equivalent will be as powerful as a proper desktop computer from 2016, that would be good.

Have been reading about small form factor computers a lot, even purchased the cubox 4 pro or what's it called, a few years back. It's not powerful enough for my needs.

Maybe in 5 years the latest and greatest rpi or equivalent will be as powerful as a proper desktop computer from 2016, that would be good.

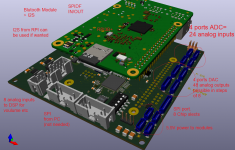

Turns out you can choose tcp/ip as interface in Sigma studio instead of USB.

And there is code for Linux available.

Meaning that you can use let the raspberry pi be the interface and your laptop will not be tied down to the board via a USB cable.

Also saves $, even tough the raspberry has a price of course, but hard (not clever) to avoid that cost.

And there is code for Linux available.

Meaning that you can use let the raspberry pi be the interface and your laptop will not be tied down to the board via a USB cable.

Also saves $, even tough the raspberry has a price of course, but hard (not clever) to avoid that cost.

You could also go to an arduino or stm32 microcontroller for about a single USD on ebay for the great clones. Steep learning curve if you are not at all familiar with embedded programming though. They are similar to the raspberry pi in that there is a huge community of people building with them. There are tons of add on boards that plug together like $3 2.5" touch screens for a user interface. I plan to do the arduino route since that is what I have laying around, and it should allow me another fun open source project for others to build on top of as well.

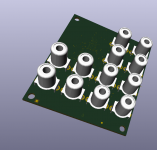

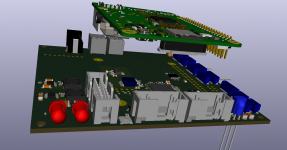

I removed the 2pcs AD1939 codecs from main board and made a separeta I/O board.

So I can put them vertical to the back of the cabinet.

Enables me to populate as many as i want and use different I/O combinations.

made a vertical pcb with 1 pcs AD1939

4 inputs at the "top"

8 outputs at the "bottom"

So I can put them vertical to the back of the cabinet.

Enables me to populate as many as i want and use different I/O combinations.

made a vertical pcb with 1 pcs AD1939

4 inputs at the "top"

8 outputs at the "bottom"

Attachments

I really like the look of that! So clean and tidy.

Only missing volume control now, but that is not so important.

Only missing volume control now, but that is not so important.

Volume control you do in the ADAU1467.

Or in the ad1939 (but I can't see why you would do that)

This is all digital.

Or in the ad1939 (but I can't see why you would do that)

This is all digital.

Maybe you refer to the human machine interface

HMI

Thats a topic....

But a rotatry knob on the front I guess is minimum.

A display.

HMI

Thats a topic....

But a rotatry knob on the front I guess is minimum.

A display.

Hi

the HMI has been moved/postponed to a universal remote.

need to get this HW produced into v1.0 as the major task will be the software.

also there is a bunch of interface cards to be made.

the HMI has been moved/postponed to a universal remote.

need to get this HW produced into v1.0 as the major task will be the software.

also there is a bunch of interface cards to be made.

Making good progress. 🙂

I have not been able to look at my ADAU1466 much, I tried several times, but the kids are shouting about something every single time I sit down to focus...

It seems to work well though, will have to put it in a box eventually. Aux ADC is working well for volume control, have been trying to make the other Aux ADC to control input selection, no success so far, it's just for fun.

I have not been able to look at my ADAU1466 much, I tried several times, but the kids are shouting about something every single time I sit down to focus...

It seems to work well though, will have to put it in a box eventually. Aux ADC is working well for volume control, have been trying to make the other Aux ADC to control input selection, no success so far, it's just for fun.

*bump*

How are things going over there dspswede?

I would like to purchase some dsp units from you if at all possible. Do not know how much help I would be in testing, but maybe I could help you "infantry proof" it. :-D

Putting together an integrated amp with DSP and 2 TPA3255 (dual mono), need to know what holes to make for whatever DSP solution I am going for. 🙂

How are things going over there dspswede?

I would like to purchase some dsp units from you if at all possible. Do not know how much help I would be in testing, but maybe I could help you "infantry proof" it. :-D

Putting together an integrated amp with DSP and 2 TPA3255 (dual mono), need to know what holes to make for whatever DSP solution I am going for. 🙂

You can get 1 pcb for free and schematics etc

I have not had time to assemble them.

But I have been thinking about it....

Hehe

I have not had time to assemble them.

But I have been thinking about it....

Hehe

But I have the solder paste screen so I realize I need to focus on getting them assembled.

Next week of to China but final parts are under procurement.

Next week of to China but final parts are under procurement.

Hmmmm. I would have to get two hot air guns and perhaps mount them to a fixture of sorts, make some adjustable PCB holders from alu profiles, would take some time to calibrate temperature and airflow to make a proper hot air station. Separate timers for the hot air guns... Starts adding up.

Do not want to use the oven in the kitchen, but it would probably be fine for the purpose...

How much would you charge to solder the chips to the board? I do not mind doing the small parts by hand, but it does delay my project some.

Do not want to use the oven in the kitchen, but it would probably be fine for the purpose...

How much would you charge to solder the chips to the board? I do not mind doing the small parts by hand, but it does delay my project some.

You could just put the pcb in a frying pan on the stove.

Mounting the big problematic chip will be no problem for me and solder it for you.

I don't need money I just need some time.

Will fix it on return from China.

Mounting the big problematic chip will be no problem for me and solder it for you.

I don't need money I just need some time.

Will fix it on return from China.

I do not have any problems soldering µBGA components or the like with just a regular hot air gun and some bricks to help with air flow and support.

It's just that I would like to do it properly, have not used a proper hot air station since 2005.

Proper cool down process is important to get the most reliable solder connections.

Edit:

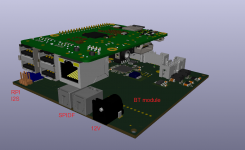

So what PCB's do you have? One for IO and one for the ADAU1467? Is there spdif conenctivity?

Is there an option to connect things to AUX ADC on the ADAU board?

It's just that I would like to do it properly, have not used a proper hot air station since 2005.

Proper cool down process is important to get the most reliable solder connections.

Edit:

So what PCB's do you have? One for IO and one for the ADAU1467? Is there spdif conenctivity?

Is there an option to connect things to AUX ADC on the ADAU board?

Last edited:

- Home

- Source & Line

- Digital Line Level

- ADAU1467 Evaluation board?