The Maelstrom subs I'm working on needed to be a bit different that the typical Sonotube as I just don’t want to have what everyone else has, plus I like to experiment and put theory to test, so I've already gone thru about 3 different volume prototypes and a least a dozen port changes while playing test tones.

That being said, I've already learned a lot about tuning a enclosure using the test tone method, and found that none of the modeling programs are exact, some not even close depending on how complex the box is.

After I found the perfect enclosure volume and tuning (266L gross with 33"x8" port for 20Hz) I found that the port wont fit down all the way into the sonotube, so I built one a bit bigger that would, then I compared the 2 side by side, both with 400W mono amps and level matched. To my surprise the smaller 266L with the 33" port sticking out sounded better than the larger 340L with the flush port, I also noted that by moving the port in and out of the enclosure I could fine tune a Hz or so.

That left me with the idea of doing something along the lines of the Polk Power Port, and since some one sent me the Spread-Sheet and program to do the calculations I decided to put a adjustable version on top of the port sticking out, first to dress up this ugly beast and allow the valve to be used as a shelf, second and most important to do some experiments with opening and closing the valve. Maybe I can actually hear it go aperiodic just before it closes.

So I have made plans to have this tulip shaped valve hovering above the opening of the port suspended by a length of all-thread rod so that it can be screwed in, and even closed off completely. The valve will be turned out of a solid block of Red Oak 8” diameter at the top tapering to about ½” at the stem where the rod will be affixed.

I modeled the 266L enclosure as a sealed and it looks quite good, not nearly as low but very good nonetheless.

The Polk paper says the stem diameter needs to be precise as well as the distance of the valve from the port opening, since the valve will be adjustable this should be easy, but I will need to play with the stem diameter to get it right.

When this thing is done it should be quite versatile, and very unique looking, as I’m also adding Oak inlays to the top (larger) disk so that it will match the inlays on my mains.

Any critiques or comments?

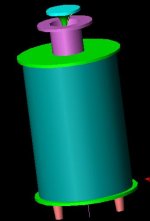

Here are AutoCAD 3-D drawings of the project, note the valve on top.

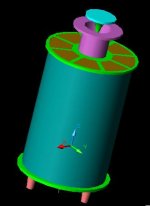

Wire frame

The Maelstrom subs I'm working on needed to be a bit different that the typical Sonotube as I just don’t want to have what everyone else has, plus I like to experiment and put theory to test, so I've already gone thru about 3 different volume prototypes and a least a dozen port changes while playing test tones.

That being said, I've already learned a lot about tuning a enclosure using the test tone method, and found that none of the modeling programs are exact, some not even close depending on how complex the box is.

After I found the perfect enclosure volume and tuning (266L gross with 33"x8" port for 20Hz) I found that the port wont fit down all the way into the sonotube, so I built one a bit bigger that would, then I compared the 2 side by side, both with 400W mono amps and level matched. To my surprise the smaller 266L with the 33" port sticking out sounded better than the larger 340L with the flush port, I also noted that by moving the port in and out of the enclosure I could fine tune a Hz or so.

That left me with the idea of doing something along the lines of the Polk Power Port, and since some one sent me the Spread-Sheet and program to do the calculations I decided to put a adjustable version on top of the port sticking out, first to dress up this ugly beast and allow the valve to be used as a shelf, second and most important to do some experiments with opening and closing the valve. Maybe I can actually hear it go aperiodic just before it closes.

So I have made plans to have this tulip shaped valve hovering above the opening of the port suspended by a length of all-thread rod so that it can be screwed in, and even closed off completely. The valve will be turned out of a solid block of Red Oak 8” diameter at the top tapering to about ½” at the stem where the rod will be affixed.

I modeled the 266L enclosure as a sealed and it looks quite good, not nearly as low but very good nonetheless.

The Polk paper says the stem diameter needs to be precise as well as the distance of the valve from the port opening, since the valve will be adjustable this should be easy, but I will need to play with the stem diameter to get it right.

When this thing is done it should be quite versatile, and very unique looking, as I’m also adding Oak inlays to the top (larger) disk so that it will match the inlays on my mains.

Any critiques or comments?

Here are AutoCAD 3-D drawings of the project, note the valve on top.

That being said, I've already learned a lot about tuning a enclosure using the test tone method, and found that none of the modeling programs are exact, some not even close depending on how complex the box is.

After I found the perfect enclosure volume and tuning (266L gross with 33"x8" port for 20Hz) I found that the port wont fit down all the way into the sonotube, so I built one a bit bigger that would, then I compared the 2 side by side, both with 400W mono amps and level matched. To my surprise the smaller 266L with the 33" port sticking out sounded better than the larger 340L with the flush port, I also noted that by moving the port in and out of the enclosure I could fine tune a Hz or so.

That left me with the idea of doing something along the lines of the Polk Power Port, and since some one sent me the Spread-Sheet and program to do the calculations I decided to put a adjustable version on top of the port sticking out, first to dress up this ugly beast and allow the valve to be used as a shelf, second and most important to do some experiments with opening and closing the valve. Maybe I can actually hear it go aperiodic just before it closes.

So I have made plans to have this tulip shaped valve hovering above the opening of the port suspended by a length of all-thread rod so that it can be screwed in, and even closed off completely. The valve will be turned out of a solid block of Red Oak 8” diameter at the top tapering to about ½” at the stem where the rod will be affixed.

I modeled the 266L enclosure as a sealed and it looks quite good, not nearly as low but very good nonetheless.

The Polk paper says the stem diameter needs to be precise as well as the distance of the valve from the port opening, since the valve will be adjustable this should be easy, but I will need to play with the stem diameter to get it right.

When this thing is done it should be quite versatile, and very unique looking, as I’m also adding Oak inlays to the top (larger) disk so that it will match the inlays on my mains.

Any critiques or comments?

Here are AutoCAD 3-D drawings of the project, note the valve on top.

Wire frame

The Maelstrom subs I'm working on needed to be a bit different that the typical Sonotube as I just don’t want to have what everyone else has, plus I like to experiment and put theory to test, so I've already gone thru about 3 different volume prototypes and a least a dozen port changes while playing test tones.

That being said, I've already learned a lot about tuning a enclosure using the test tone method, and found that none of the modeling programs are exact, some not even close depending on how complex the box is.

After I found the perfect enclosure volume and tuning (266L gross with 33"x8" port for 20Hz) I found that the port wont fit down all the way into the sonotube, so I built one a bit bigger that would, then I compared the 2 side by side, both with 400W mono amps and level matched. To my surprise the smaller 266L with the 33" port sticking out sounded better than the larger 340L with the flush port, I also noted that by moving the port in and out of the enclosure I could fine tune a Hz or so.

That left me with the idea of doing something along the lines of the Polk Power Port, and since some one sent me the Spread-Sheet and program to do the calculations I decided to put a adjustable version on top of the port sticking out, first to dress up this ugly beast and allow the valve to be used as a shelf, second and most important to do some experiments with opening and closing the valve. Maybe I can actually hear it go aperiodic just before it closes.

So I have made plans to have this tulip shaped valve hovering above the opening of the port suspended by a length of all-thread rod so that it can be screwed in, and even closed off completely. The valve will be turned out of a solid block of Red Oak 8” diameter at the top tapering to about ½” at the stem where the rod will be affixed.

I modeled the 266L enclosure as a sealed and it looks quite good, not nearly as low but very good nonetheless.

The Polk paper says the stem diameter needs to be precise as well as the distance of the valve from the port opening, since the valve will be adjustable this should be easy, but I will need to play with the stem diameter to get it right.

When this thing is done it should be quite versatile, and very unique looking, as I’m also adding Oak inlays to the top (larger) disk so that it will match the inlays on my mains.

Any critiques or comments?

Here are AutoCAD 3-D drawings of the project, note the valve on top.

Attachments

Hello KindDaddy!

Nice 3D modeling.

I see two things wrong with the design.

(1) The enclosure will have no loading capability with port at the top, you will get less bass out of this design than Polk Audio does as Polks's design relies on floor/wall interaction (as most subs do) to aquire some DB gain.

(2) With the Polk design, the floor & base of the speaker are as much of a factor as the rest of the 'Power Port'. Bass is so omni directional that I do not believe that having the 'tulip shaped valve' on top will do much if the floor and base of the speaker are not there to work in unison.

(3) Closing the 'tulip' too much will be an invitation to port noise.

Also, with a port, it does not matter too much whether the port tube is in the box flush or sticking out of the box some, the port is still the same length.

Just some thoughts.

Thanks

KevinLee🙂

Nice 3D modeling.

I see two things wrong with the design.

(1) The enclosure will have no loading capability with port at the top, you will get less bass out of this design than Polk Audio does as Polks's design relies on floor/wall interaction (as most subs do) to aquire some DB gain.

(2) With the Polk design, the floor & base of the speaker are as much of a factor as the rest of the 'Power Port'. Bass is so omni directional that I do not believe that having the 'tulip shaped valve' on top will do much if the floor and base of the speaker are not there to work in unison.

(3) Closing the 'tulip' too much will be an invitation to port noise.

Also, with a port, it does not matter too much whether the port tube is in the box flush or sticking out of the box some, the port is still the same length.

Just some thoughts.

Thanks

KevinLee🙂

KevinLee said:Hello KindDaddy!

Nice 3D modeling.

I see two things wrong with the design.

(1) The enclosure will have no loading capability with port at the top, you will get less bass out of this design than Polk Audio does as Polk's design relies on floor/wall interaction (as most subs do) to acquire some DB gain.

(2) With the Polk design, the floor & base of the speaker are as much of a factor as the rest of the 'Power Port'. Bass is so omni directional that I do not believe that having the 'tulip shaped valve' on top will do much if the floor and base of the speaker are not there to work in unison.KevinLee🙂

Good point, this seems logical, however the corner loading will help some, and even if it doesn’t work the same as the Polk design, the primary idea should still work, which it to go sealed by screwing the plug all the way in.

Originally posted by KevinLee (3) Closing the 'tulip' too much will be an invitation to port noise.[/B]

This is something I would like to expermint with, so far theory has shown to be not exact according to my prototypes.

Originally posted by KevinLee Also, with a port, it does not matter too much whether the port tube is in the box flush or sticking out of the box some, the port is still the same length.

KevinLee🙂 [/B]

This is also true about port length, but is since there isn't enough room for the port in the box, I don’t have much a choice unless I go with the bigger box, which I didn’t like compared to the smaller one. BTW it does matter for tuning sake how much volume the port takes up in the box, I've already proved this to myself.

Thanks for your input you make some good observations, just what i was looking for, two brains are better than one.

Hello again KingDaddy,

I have learned much from the forums and always welcome others ideas or experiences as well.

One more idea:

If you make your port diameter smaller you will be able to shorten it by the corresponding percentage.

Eg. Take a 4"port down to a 3"port, you will need to shorten it 25% to achieve same sound.

Thanks again

KevinLee

I have learned much from the forums and always welcome others ideas or experiences as well.

One more idea:

If you make your port diameter smaller you will be able to shorten it by the corresponding percentage.

Eg. Take a 4"port down to a 3"port, you will need to shorten it 25% to achieve same sound.

Thanks again

KevinLee

KevinLee said:Hello again KingDaddy,

I have learned much from the forums and always welcome others ideas or experiences as well.

One more idea:

If you make your port diameter smaller you will be able to shorten it by the corresponding percentage.

Eg. Take a 4"port down to a 3"port, you will need to shorten it 25% to achieve same sound.

Thanks again

KevinLee

No, I dont think the port diameter is a linear function of the length, I do know that multiple ports will be longer than a single though.

Actually i'd have to say you are both somewhat right...although port length is in relevance to cross sectional area which does incorporate diameter, the equation is much more complex than that...jl audio (the car audio manufacturer) has some really good tutorials on port construction at their site...jlaudio.com...and although moving the port in and out of the box will not make the port and higher or lower tuned itself, it will as it interacts with the box volume displacing less or more air for the vent itself...this probably works with your design because port displacement may have been forgotten to be compensated for...just a thought...also i dont really see why you would really make a speaker that was designed for an application such as a vented box to go to an aperiodic enclosure...but i really like the approach youre taking by not letting the normal rules of audio take over...who knows you may have something that you end up really liking and as quite the conversation starter

Something I find very interesting about modeling vs. real tests is that none of the modeling programs account for the port volume, everything is calculated by Gross Volume, not Net.

This is a problem as I've tried about 5 different port lengths several different volumes and many different configurations of the port partially in and out of the enclosure.

What this has shown me is that the modeling programs will get you close, and probably very close if you carefully calculate exact Net Volume, but you still have to fine tune in the real world, and sometimes the modeling isn't even close at all so you still have to prove it when your done.

The Test Tone method works so well I cant imagine doing it any other way, and when your done your sure of the exact Tuning of the enclosure, plus playing a strong 20Hz sine wave will let you know if there is any chance of port noise.

Theory is all fine and well and a great tool to cut down on unnecessary mistakes, but in the end the real world tests is what matters.

Thanks for you input.

This is a problem as I've tried about 5 different port lengths several different volumes and many different configurations of the port partially in and out of the enclosure.

What this has shown me is that the modeling programs will get you close, and probably very close if you carefully calculate exact Net Volume, but you still have to fine tune in the real world, and sometimes the modeling isn't even close at all so you still have to prove it when your done.

The Test Tone method works so well I cant imagine doing it any other way, and when your done your sure of the exact Tuning of the enclosure, plus playing a strong 20Hz sine wave will let you know if there is any chance of port noise.

Theory is all fine and well and a great tool to cut down on unnecessary mistakes, but in the end the real world tests is what matters.

Thanks for you input.

<b>One</b> theory stated behind the "Power Port" is that it keeps the air flow "laminar". The theory behind the B&W port with the dimples is same as golf balls. Why golf balls and B&W ports are dimpled is to make the air flow around it "turbulent" (The exact <b>opposite</b> of "laminar"). Turbulent flow offers less resistance. Totally laminar flow, I assume, reduced noise, since the "transition" between laminar flow and turbulent flow is wacky...?

I don't have (or remember) the working knowledge to figure out whether a given port (air) velocity for a given port is high enough to transition to turbulent, or if it's too slow to transition to turbulent even with dimples, but I just thought I would throw out some terms as a starting place for your research about "fluid dynamics". Maybe in the end you can tell us all something like:

<i>

If the port velocity is above X, add dimples, and if you port velocity is below X, add a power port.

</i>

That would really help alot of people, I think.

I don't have (or remember) the working knowledge to figure out whether a given port (air) velocity for a given port is high enough to transition to turbulent, or if it's too slow to transition to turbulent even with dimples, but I just thought I would throw out some terms as a starting place for your research about "fluid dynamics". Maybe in the end you can tell us all something like:

<i>

If the port velocity is above X, add dimples, and if you port velocity is below X, add a power port.

</i>

That would really help alot of people, I think.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Adaptation on the Polk Power Port